Alkyne liquid crystal compound, preparation method, composition containing compound and high-frequency assembly containing liquid crystal medium

A liquid crystal compound and liquid crystal composition technology, applied in chemical instruments and methods, liquid crystal materials, etc., to achieve the effects of low dielectric loss, wide nematic phase temperature range, and short synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

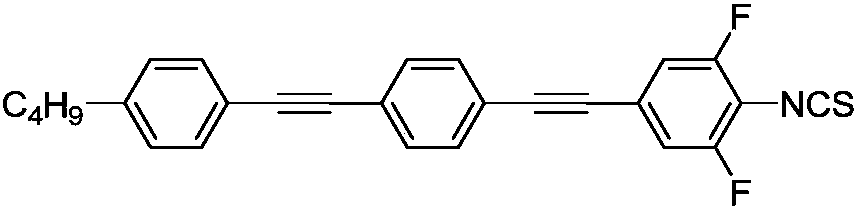

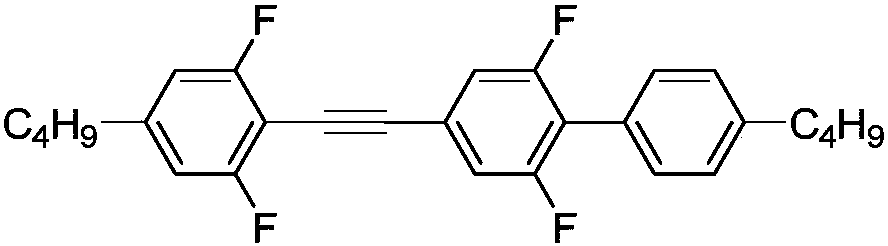

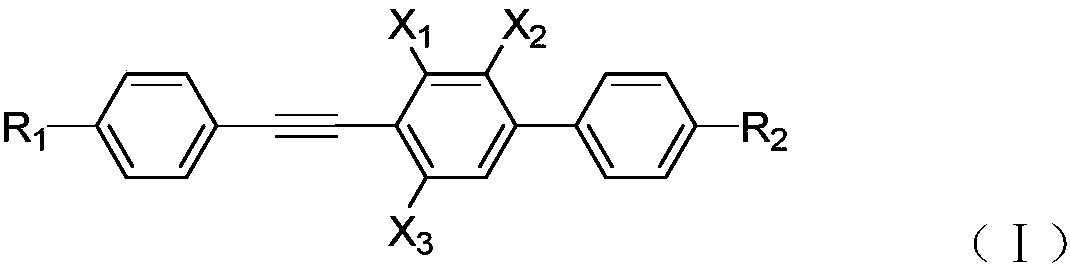

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of 4'-ethyl-2-methyl-4-((4-propylphenyl)ethynyl)-1,1'-biphenyl

[0037] The specific structure is as follows:

[0038]

[0039] The preparation process is as follows:

[0040] Step 1: Synthesis of 1-bromo-2-methyl-4-((4-propylphenyl)ethynyl)benzene

[0041]

[0042] Under nitrogen protection, in the there-necked flask, add 1-bromo-4-iodo-2-methylbenzene (20g, 0.067mol), bis(triphenylphosphine) palladium dichloride (0.48g, 1% mol), iodine Cuprous (0.38g, 3%mol), PPh 3 (0.54 g, 3% mol), triethylamine 250 mL. Propylphenylacetylene (9.7 g, 0.067 mol) was added dropwise at 10° C., and the reaction was incubated for 2 h for post-treatment. Filter the reaction solution, add n-heptane to dissolve the filtrate after rotary evaporation, wash with water until neutral, filter after drying with anhydrous magnesium sulfate, perform column chromatography on the filtrate, and recrystallize the eluate after rotary evaporation to obtain 15.7 g of solid, GC purity 99.49...

Embodiment 2

[0051] Synthesis of 2-methyl-4'-propyl-4-((4-propylphenyl)ethynyl)-1,1'-biphenyl

[0052] The specific structure is as follows:

[0053]

[0054] Use propylbenzene boronic acid to replace the ethyl benzene boronic acid in Example 1 step (2), adopt the same method as Example 1 to synthesize 2-methyl-4'-propyl-4-((4-propylbenzene Synthesis of yl)ethynyl)-1,1'-biphenyl.

Embodiment 3

[0056] Synthesis of 4'-butyl-2-methyl-4-((4-propylphenyl)ethynyl)-1,1'-biphenyl

[0057] The specific structure is as follows:

[0058]

[0059] Using butylbenzene boronic acid to replace the ethyl benzene boronic acid in the step (2) of Example 1, 4'-butyl-2-methyl-4-((4-propylbenzene was synthesized by the same method as in Example 1) yl)ethynyl)-1,1'-biphenyl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com