AlGaN/GaN schottky diode with Al component gradually changed and preparation method thereof

A Schottky diode and diode technology, applied in the field of microelectronics, can solve the problems that the concentration of two-dimensional electron gas is not high enough, and is not suitable for higher frequency and larger current working conditions, so as to reduce material stress, increase concentration, and improve The effect of device speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

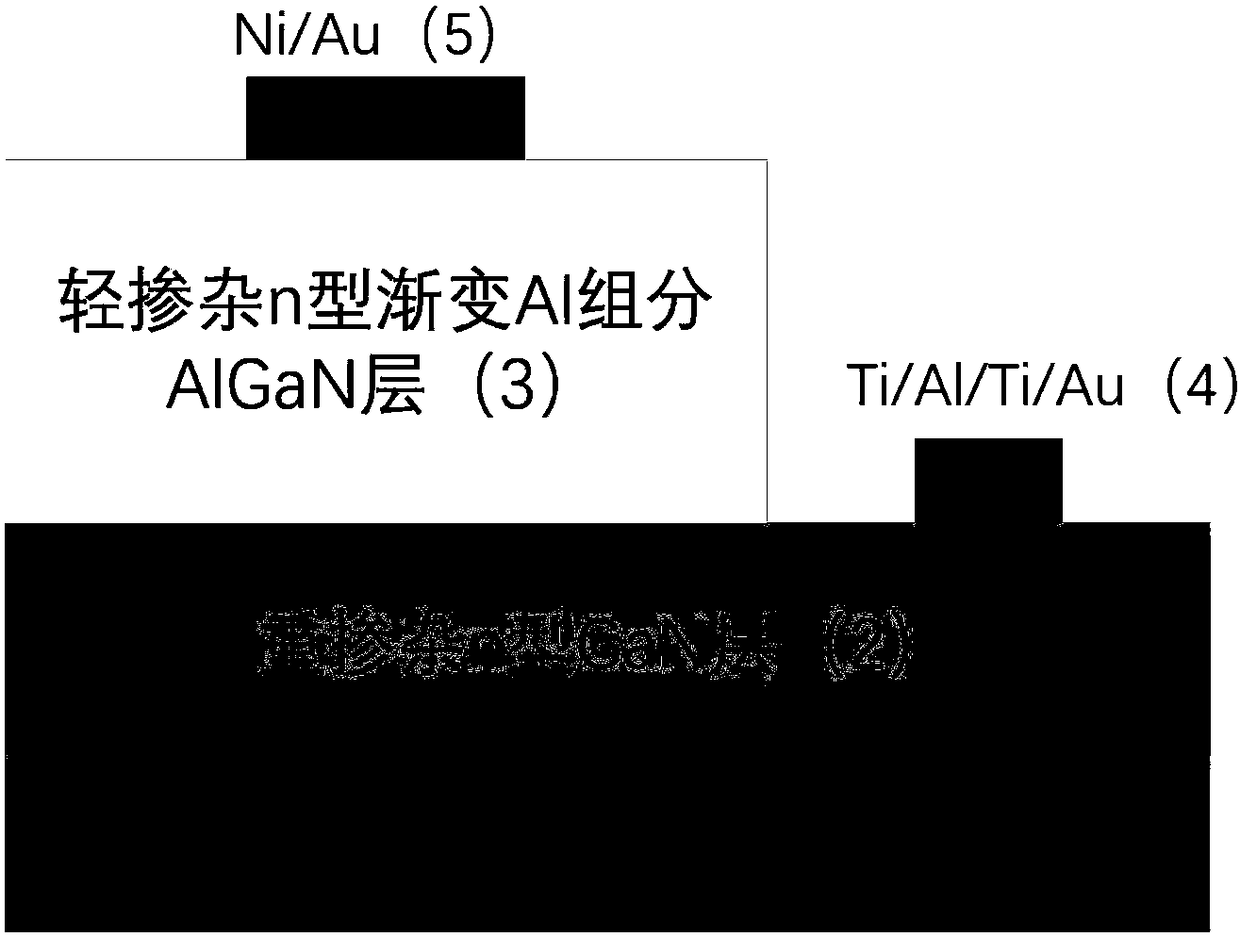

[0029] Example 1, the preparation of heavily doped n-type concentration is 10 18 cm -3 , the lightly doped n-type concentration is 10 14 cm -3 Graded Al composition AlGaN / GaN Schottky diodes.

[0030] Step one, heat treatment.

[0031] After the sapphire substrate was polished and cleaned, it was placed in the metal organic chemical vapor deposition MOCVD reaction chamber, and the vacuum degree of the reaction chamber was reduced to 2×10 -2 Torr;

[0032] Introduce hydrogen gas into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 20 Torr, the substrate is heated to a temperature of 1200° C. and kept for 10 minutes to complete the heat treatment of the substrate.

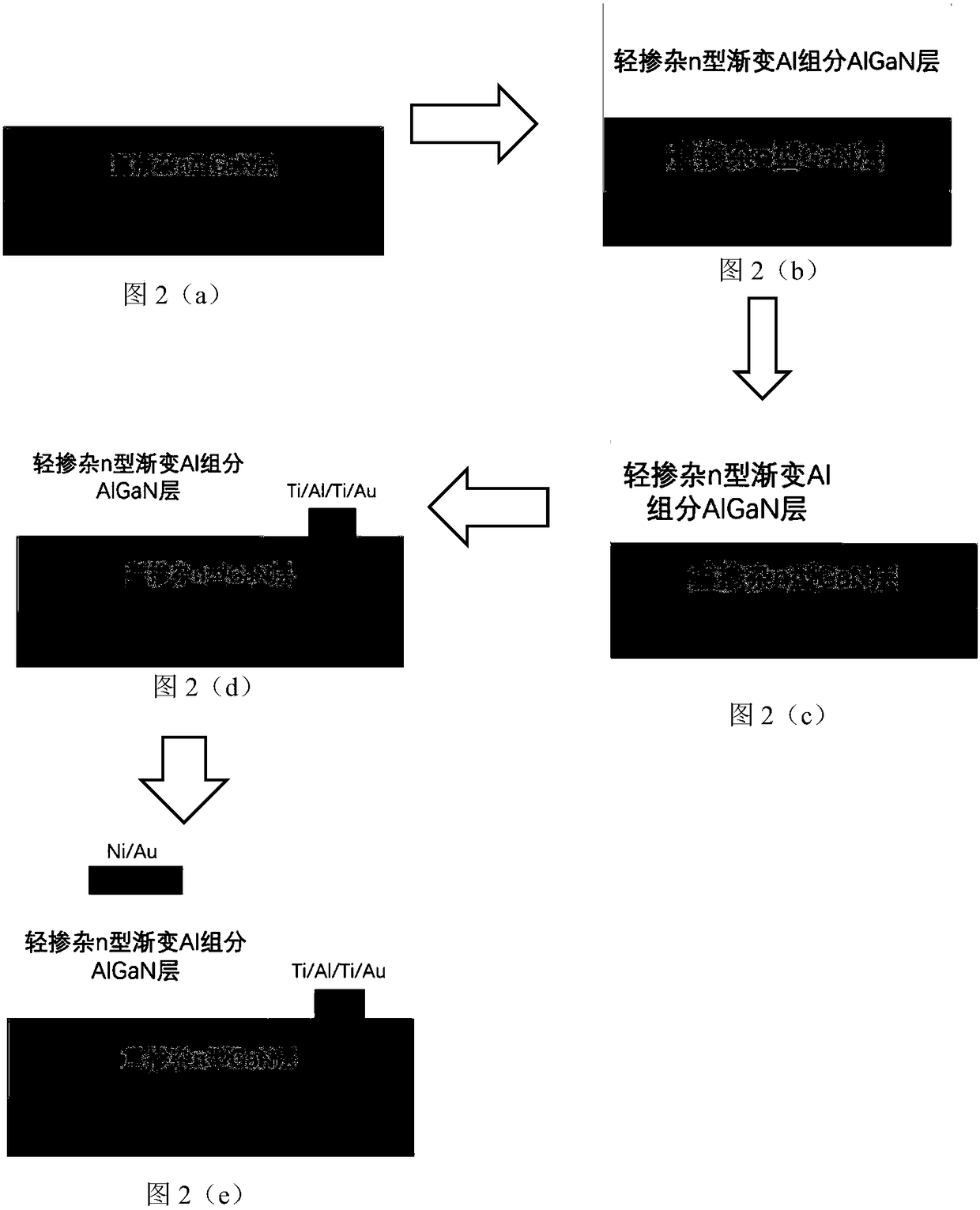

[0033] Step 2, growing a heavily doped n-type non-polar GaN layer, as shown in Figure 2(a).

[0034] The MOCVD process was adopted on the sapphire substrate. Under the condition of the reaction chamber temperature of 1000°C, the ammonia gas with a flow rate ...

Embodiment 2

[0042] Example 2, the preparation of heavily doped n-type concentration is 10 20 cm -3 , the lightly doped n-type concentration is 10 16 cm -3 Graded Al composition AlGaN / GaN Schottky diodes.

[0043] Step 1, heat treatment.

[0044] The specific implementation of this step is the same as step 1 of Embodiment 1.

[0045] Step 2, growing a heavily doped n-type non-polar GaN layer, as shown in Figure 2(a).

[0046] The MOCVD process is adopted on the sapphire substrate, and the temperature of the reaction chamber is set to 1100°C. At the same time, ammonia gas with a flow rate of 3000 sccm, a gallium source with a flow rate of 200 sccm, and a silicon source with a flow rate of 80 sccm are introduced into the reaction chamber. A heavily doped n-type non-polar GaN layer with a thickness of 2 μm was grown under the conditions, in which the silicon doping concentration was 10 20 cm -3 .

[0047] Step 3, growing a lightly doped n-type graded Al composition AlGaN layer.

[00...

Embodiment 3

[0054] Example 3, the preparation of heavily doped n-type concentration is 10 19 cm -3 , the lightly doped n-type concentration is 10 15 cm -3 Graded Al composition AlGaN / GaN Schottky diodes.

[0055] Step A, heat treatment.

[0056] The specific implementation of this step is the same as step 1 of Embodiment 1.

[0057] Step B, growing a heavily doped n-type non-polar GaN layer, as shown in Figure 2(a).

[0058] Place the heat-treated sapphire substrate in the reaction chamber, heat the reaction chamber to 1080°C, and simultaneously feed ammonia gas with a flow rate of 2500 sccm, a gallium source with a flow rate of 150 sccm, and a silicon source with a flow rate of 70 sccm, at a pressure of 40 Torr Under the conditions of growth thickness of 3 μm and silicon doping concentration of 10 19 cm -3 A heavily doped n-type nonpolar GaN layer.

[0059] Step C, growing a lightly doped n-type graded Al composition AlGaN layer.

[0060] C1) Place the substrate grown on the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com