Environment-friendly building cement

A construction cement and environmental protection technology, applied in the direction of cement production, etc., can solve the problems of increased manufacturing costs, complex production processes, environmental pollution, etc., and achieve the effects of reduced usage, excellent comprehensive performance, and better comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

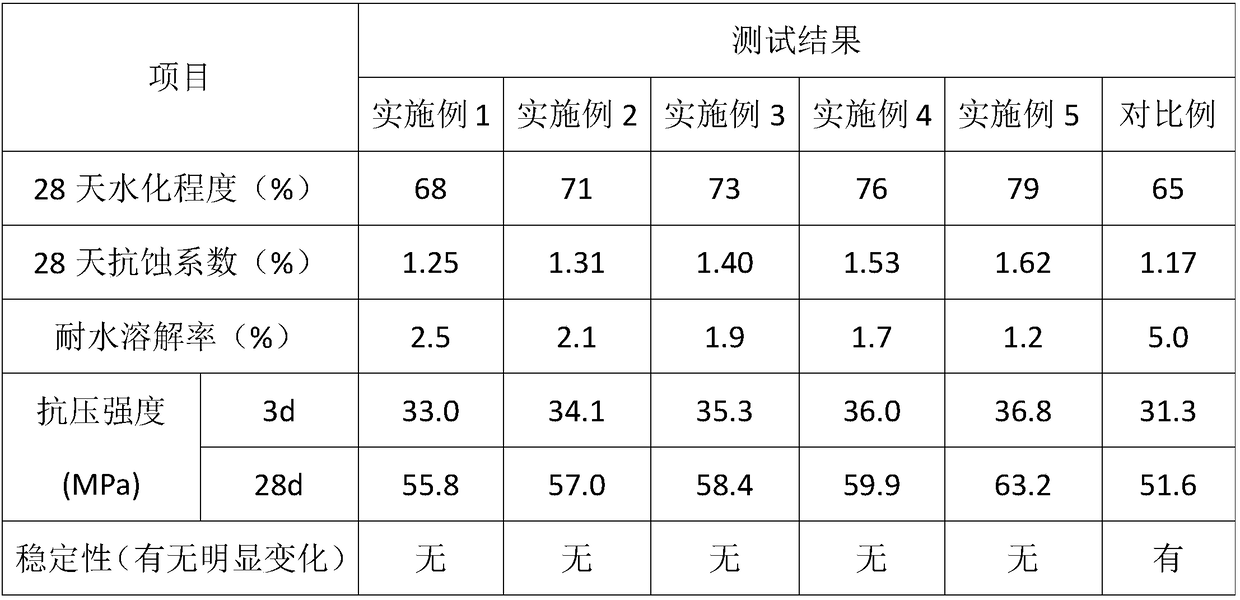

Examples

Embodiment 1

[0026] An environmentally friendly building cement, made of the following components by weight: 55 parts of cement clinker, 5 parts of modified hair fiber, 3 parts of nano boron fiber, 10 parts of olivine powder, 1 part of rare earth slag, and 1 part of functional additive;

[0027] The functional additive is prepared by solution copolymerization of vinyl borate pinacol ester, vinyl phosphate dimethyl ester, methyl acrylate and trans-zeatin glucoside.

[0028] The preparation method of described modified hair fiber, comprises the steps:

[0029] Ⅰ Disperse 30 g of shredded hair fibers in 150 g of ethanol to form a dispersion, then add 2 g of γ-glycidyl etheroxypropyl trimethoxysilane to it, stir and react at room temperature for 3 hours, then filter and wash with ethanol for 3 hours Once again, place it in a vacuum drying oven at 70°C for 10 hours to obtain epoxy-modified hair fibers;

[0030] II Disperse 20 g of the epoxy-modified hair fibers prepared in step I in 100 g of e...

Embodiment 2

[0033] An environmentally friendly building cement, made of the following components by weight: 58 parts of cement clinker, 7 parts of modified hair fiber, 5 parts of nano-boron fiber, 12 parts of olivine powder, 2 parts of rare earth slag, and 2 parts of functional additives;

[0034] The functional additive is prepared by solution copolymerization of vinyl borate pinacol ester, vinyl phosphate dimethyl ester, methyl acrylate and trans-zeatin glucoside.

[0035] The preparation method of described modified hair fiber, comprises the steps:

[0036] Ⅰ Disperse 35 g of shredded hair fibers in 170 g of ethanol to form a dispersion, then add 2 g of γ-glycidyl etheroxypropyl trimethoxysilane to it, stir and react at room temperature for 3.5 hours, then filter and wash with ethanol for 4 Once again, placed in a vacuum drying oven at 73°C for 10.5 hours to obtain epoxy-modified hair fibers;

[0037] II Disperse 25g of the epoxy-modified hair fiber prepared in step I in 130g of isopr...

Embodiment 3

[0040] An environmentally friendly building cement, made of the following components by weight: 60 parts of cement clinker, 8 parts of modified hair fiber, 6 parts of nano-boron fiber, 13 parts of olivine powder, 3 parts of rare earth slag, and 3 parts of functional additives;

[0041] The functional additive is prepared by solution copolymerization of vinyl borate pinacol ester, vinyl phosphate dimethyl ester, methyl acrylate and trans-zeatin glucoside.

[0042] The preparation method of described modified hair fiber, comprises the steps:

[0043] Ⅰ Disperse 40 g of shredded hair fibers in 180 g of ethanol to form a dispersion, then add 2 g of γ-glycidyl etheroxypropyl trimethoxysilane to it, stir and react at room temperature for 4 hours, then filter and wash with ethanol for 5 Once again, placed in a vacuum drying oven at 75°C for 11 hours to obtain epoxy-modified hair fibers;

[0044] II Disperse 30 g of the epoxy-modified hair fiber prepared in step I in 140 g of dichlorom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com