Preparation method of alkali phenolic resin for 3D sand mold printing

A technology of phenolic resin and sand mold, which is applied in the field of foundry adhesives and organic chemistry, can solve the problems of unfavorable secondary curing and fluidity of resin sand, unable to meet the needs of 3D sand mold printing, poor high temperature resistance, etc., to achieve good application and Development prospects, good development potential and application prospects, and the effect of improving curing speed and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

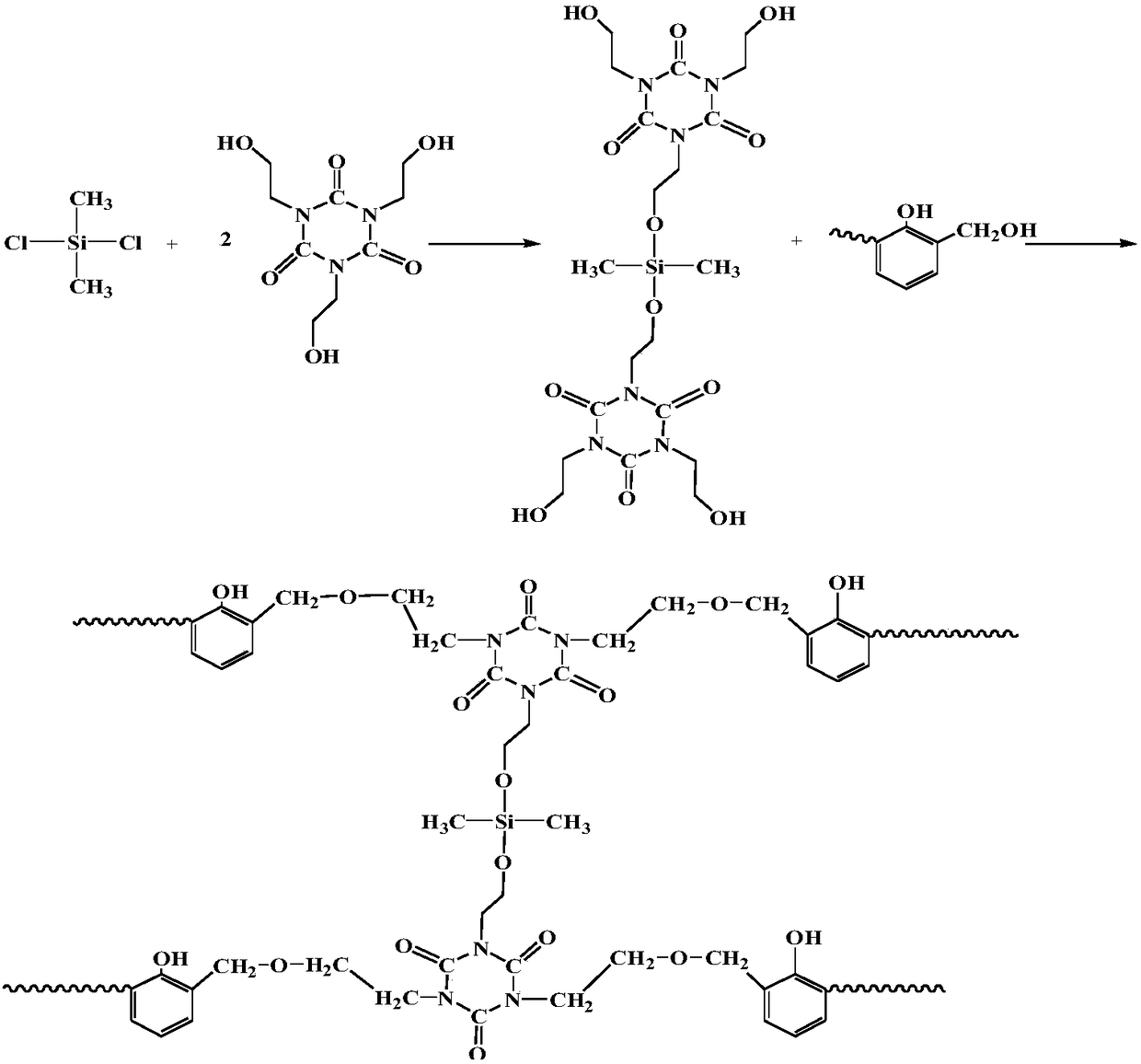

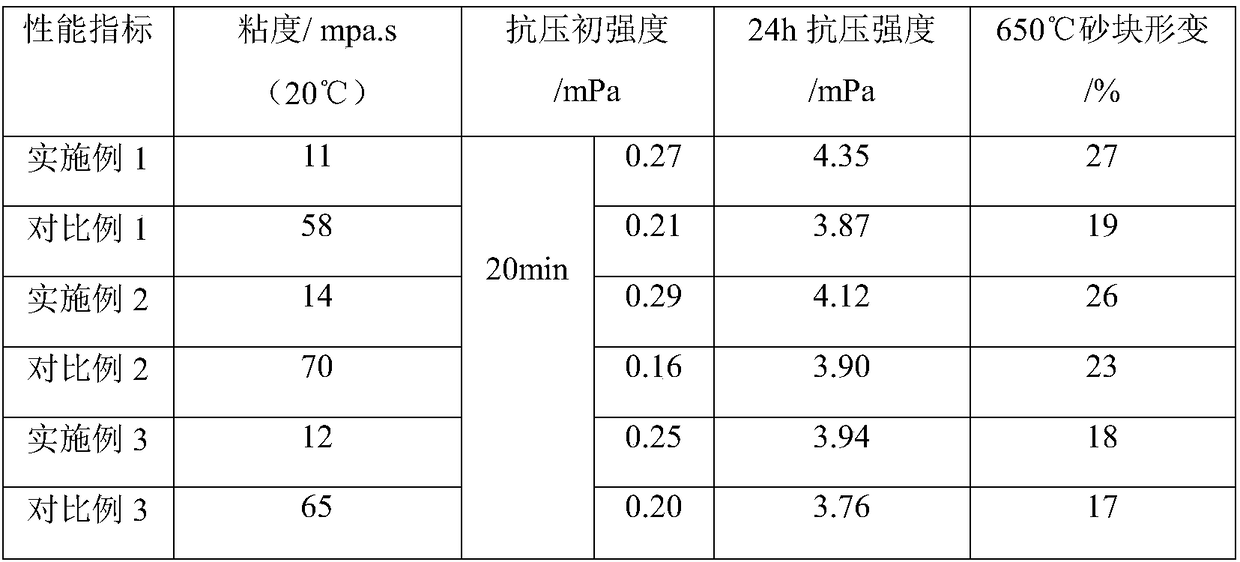

[0035] In a 250ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser, and a drying tube at the top of the condenser, replace the air in the bottle with nitrogen, and add 26.2g (0.1mol) (2-hydroxy Ethyl) isocyanurate and 50ml tetrachloroethane, and heated up to 50 ~ 70 ℃, dissolved under stirring; 4.68g (0.05mol) of dimethyl chlorosilane was added dropwise, and the reaction temperature was controlled during the dropwise addition process. Not higher than 70°C; after dripping, raise the temperature to 90°C, and react for 5 hours; after the HCl gas is released, add 0.9g sodium hydroxide, keep stirring for 1 hour, and detect that the pH of the solution is 5-6 as the reaction end point; Organic solvents are recycled for use to obtain phenolic resin modifiers;

[0036] Weigh 100g of phenol, 30g of modifier, and 8.4g of 30% sodium hydroxide solution in a 500ml reaction kettle, and raise the temperature to 78-80°C, then add 140g of formaldehyde d...

Embodiment 2

[0038] In a 250ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser, and a drying tube on the top of the condenser, replace the air in the bottle with nitrogen, and add 26.2g (0.1mol) (2-hydroxy Ethyl) isocyanurate and 45ml of dioxane, and heated to 50 ~ 70 ° C, dissolved under stirring; 4.68g (0.05mol) of dimethyl chlorosilane was added dropwise, and the reaction temperature was controlled during the dropwise addition process. Not higher than 70°C; after dripping, raise the temperature to 95°C, and react for 2 hours; after the HCl gas is released, add 0.7g sodium hydroxide, keep stirring for 1 hour, and detect that the pH of the solution is 5-6 as the reaction end point; Organic solvents are recycled for use to obtain phenolic resin modifiers;

[0039] Weigh 90g of phenol, 10g of resorcinol, 20g of modifier and 4.9g of 40% potassium hydroxide solution into a 500ml reaction kettle, and raise the temperature to 74-76°C, then add 105g of ...

Embodiment 3

[0041] In a 250ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser, and a drying tube on the top of the condenser, replace the air in the bottle with nitrogen, and add 26.2g (0.1mol) (2-hydroxy Ethyl) isocyanurate and 60ml ethylene glycol dimethyl ether, and heated to 50 ~ 70 ° C, dissolved under stirring; dropwise added 4.68g (0.05mol) of dimethyl chlorosilane, dropwise process control The reaction temperature is not higher than 70°C; after dripping, raise the temperature to 90°C, and react for 4 hours; after the HCl gas is released, add 0.7g of sodium hydroxide, keep stirring for 1 hour, and detect that the pH of the solution is 5-6 as the reaction end point; Evaporate the organic solvent and recycle it for later use to obtain a phenolic resin modifier;

[0042] Weigh 80g of phenol, 20g of o-cresol, 10g of modifier and 7.6g of 30% sodium hydroxide solution in a 500ml reaction kettle, and raise the temperature to 78-80°C, then add 95g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com