Liquid crystal compound containing dibenzofuran ring as well as preparation method and application thereof

A technology of liquid crystal compounds and liquid crystal compositions, applied in chemical instruments and methods, organic chemistry, liquid crystal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a kind of liquid crystal compound a, its chemical formula is

[0067]

[0068] Its synthetic route is as follows:

[0069]

[0070]

[0071] The specific operation steps are as follows:

[0072] 1) Synthesis of a-1

[0073] Add 10g of 2-bromo-4-fluorophenol, 3.15g of sodium hydroxide, and 50g of water to a 250mL three-necked flask in sequence, stir until completely dissolved, add 8.6g of ethyl chloroformate dropwise, and react at room temperature for 1 hour after the dropwise addition. The lower product a-1 was obtained, 13.8 g, with a yield of 100% and a main content >99%.

[0074] 2) Synthesis of a-2

[0075] Add 13.8g of a-1 and 61.6g of concentrated sulfuric acid to a 250mL three-necked flask in turn, stir and cool down to 0°C, add 18.5g of potassium nitrate, control the temperature at 0°C, and react for 1 hour after adding, then pour the reaction solution into stirred ice water, Product a-2 was obtained by filtration, 16g, yiel...

Embodiment 2

[0098] This embodiment provides a kind of liquid crystal compound b, its chemical formula is

[0099]

[0100] Its synthetic route is as follows:

[0101]

[0102] The specific operation steps are as follows:

[0103] 1) The synthesis of a-10 is the same as in Example 1;

[0104] 2) Synthesis of b

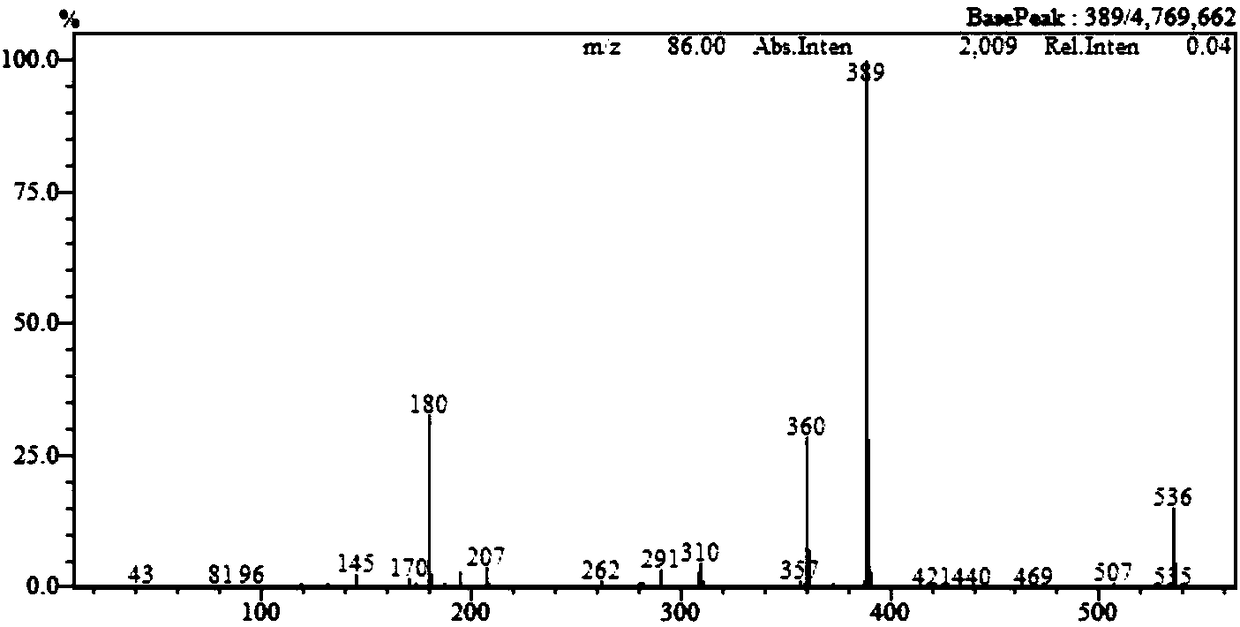

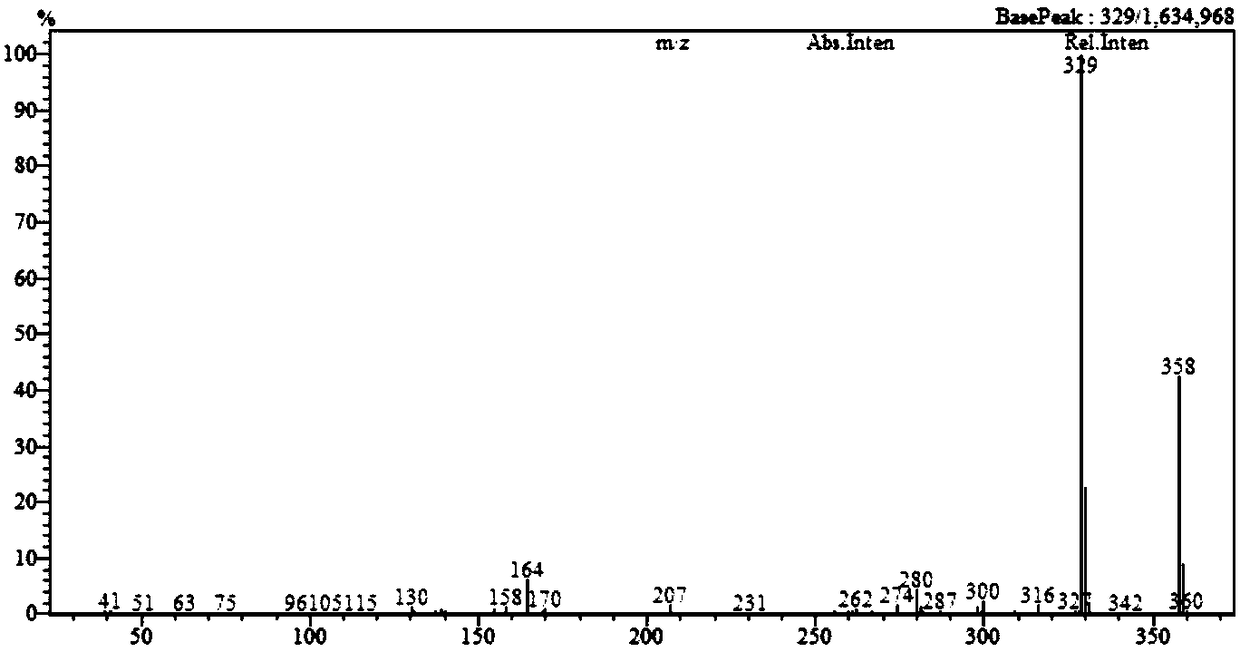

[0105] Add 1.5g of a-10, 0.74g of 3,4,5-trifluorophenylboronic acid, 1.2g of potassium carbonate, 0.3g of tetrabutylammonium bromide, palladium catalyst, and 12g of toluene to a 100mL three-necked flask protected by nitrogen. Ethanol 1.5g, water 1.5g, heated to reflux for 1h, acidified with hydrochloric acid, washed with water and concentrated, recrystallized from toluene ethanol to obtain 0.3g of product, GC: 99%, yield 40%, its mass spectrum is as follows figure 2 shown.

[0106] The clearing point of compound b is 44°C, the birefringence is 0.1661, and the dielectric anisotropy is 20.13.

Embodiment 3

[0108] This embodiment provides a kind of liquid crystal compound c, its chemical formula is

[0109]

[0110] Its synthetic route is as follows:

[0111]

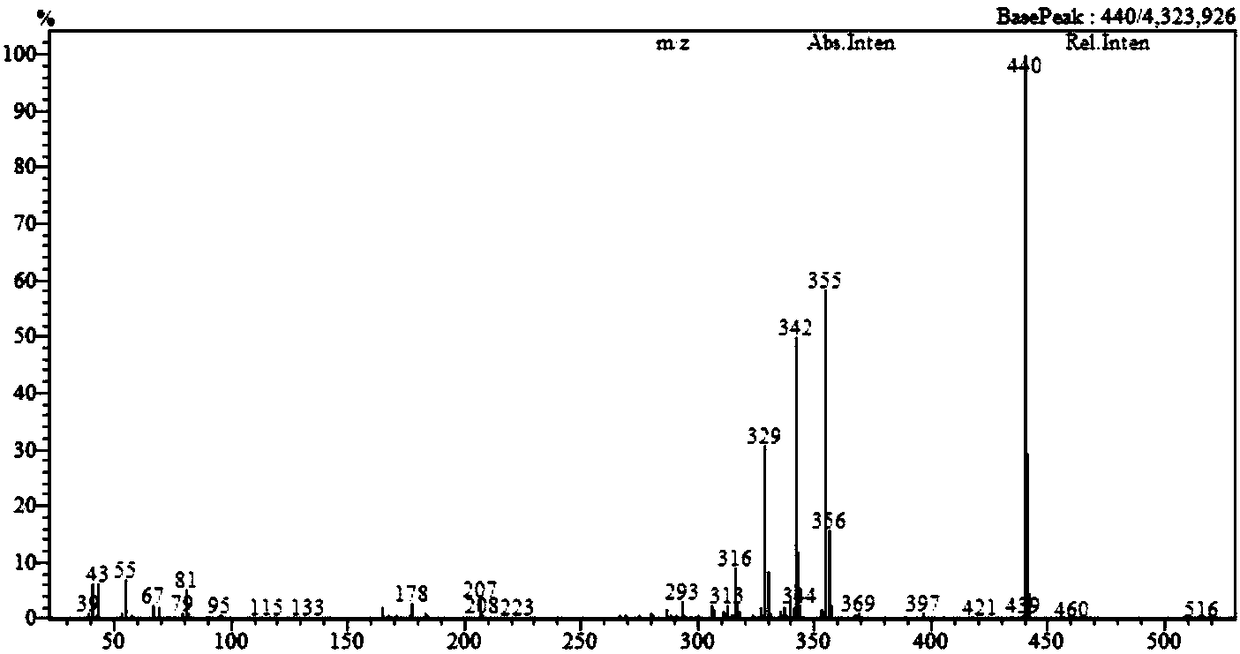

[0112] The specific operation steps are as follows:

[0113] 1) Synthesis of c-1

[0114] Add 5g of 2-bromo-4-fluoro-5-nitrophenol, 6.7g of 2-fluoro-4-propylphenylboronic acid, 1.7g of potassium carbonate, and 1.7g of tetrabutylammonium bromide to a 250mL three-necked flask protected by nitrogen. , palladium catalyst, 40g of toluene, 5g of water, 5g of ethanol, heated to reflux for 3h, extracted with hydrochloric acid, extracted with ethyl acetate, washed with water, and concentrated to obtain a crude product with a yield of 70% and a main content of >50%.

[0115] 2) Synthesis of c-2

[0116] Add 4g of c-1, 4.4g of potassium carbonate, and 20g of DMF to a 250mL three-necked flask in sequence, heat up to reflux for 5 hours, evaporate half of the DMF, pour the reaction solution into 10 times the water and stir, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com