An oil smoke filtration system

A technology of oil fume filtration and oil fume separator, which is applied in the direction of oil fume removal, dispersed particle filtration, household heating, etc., which can solve the problems of high operating cost, environmental pollution, and low cost, so as to avoid cleaning and maintenance, eliminate air pollution, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

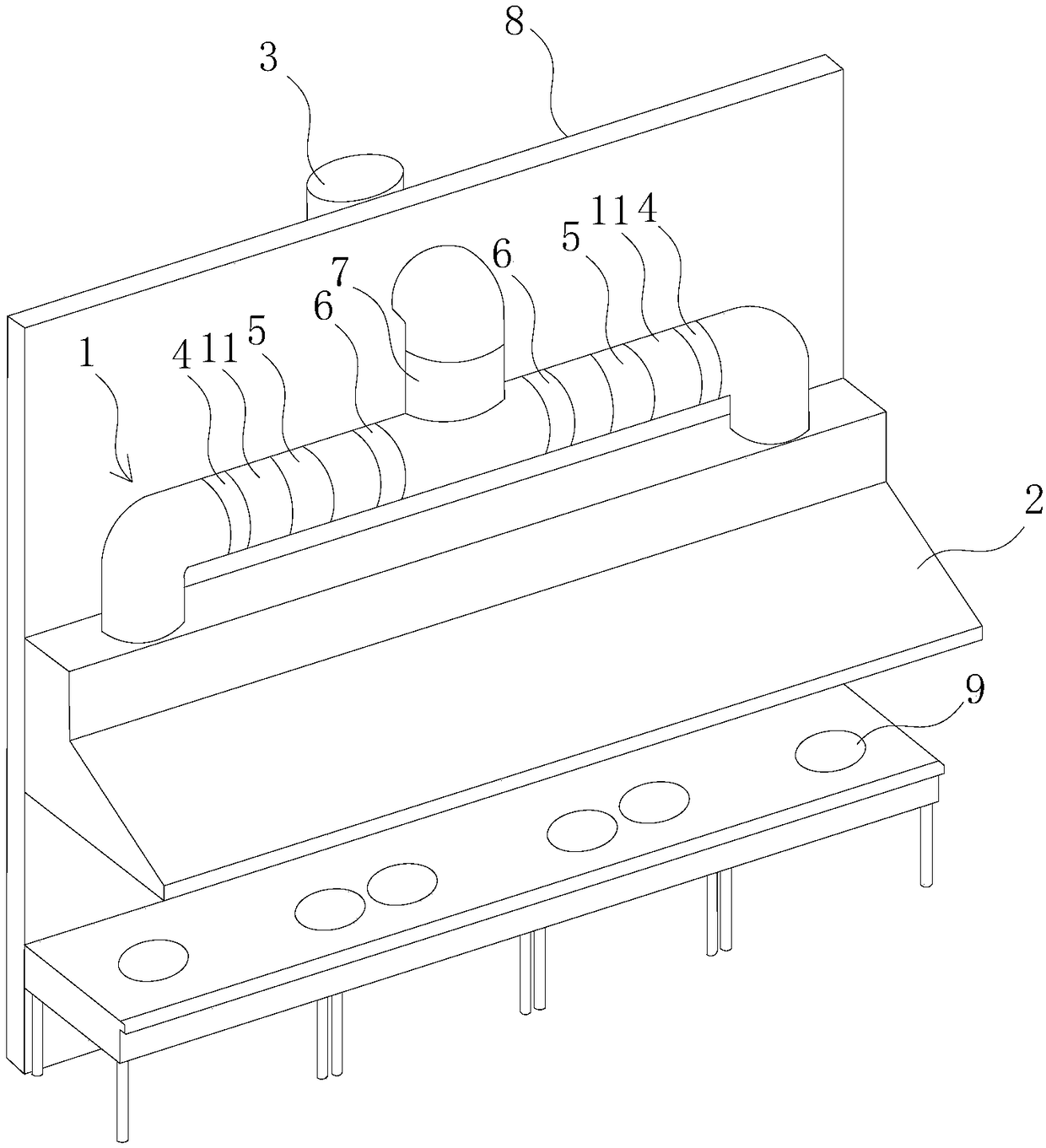

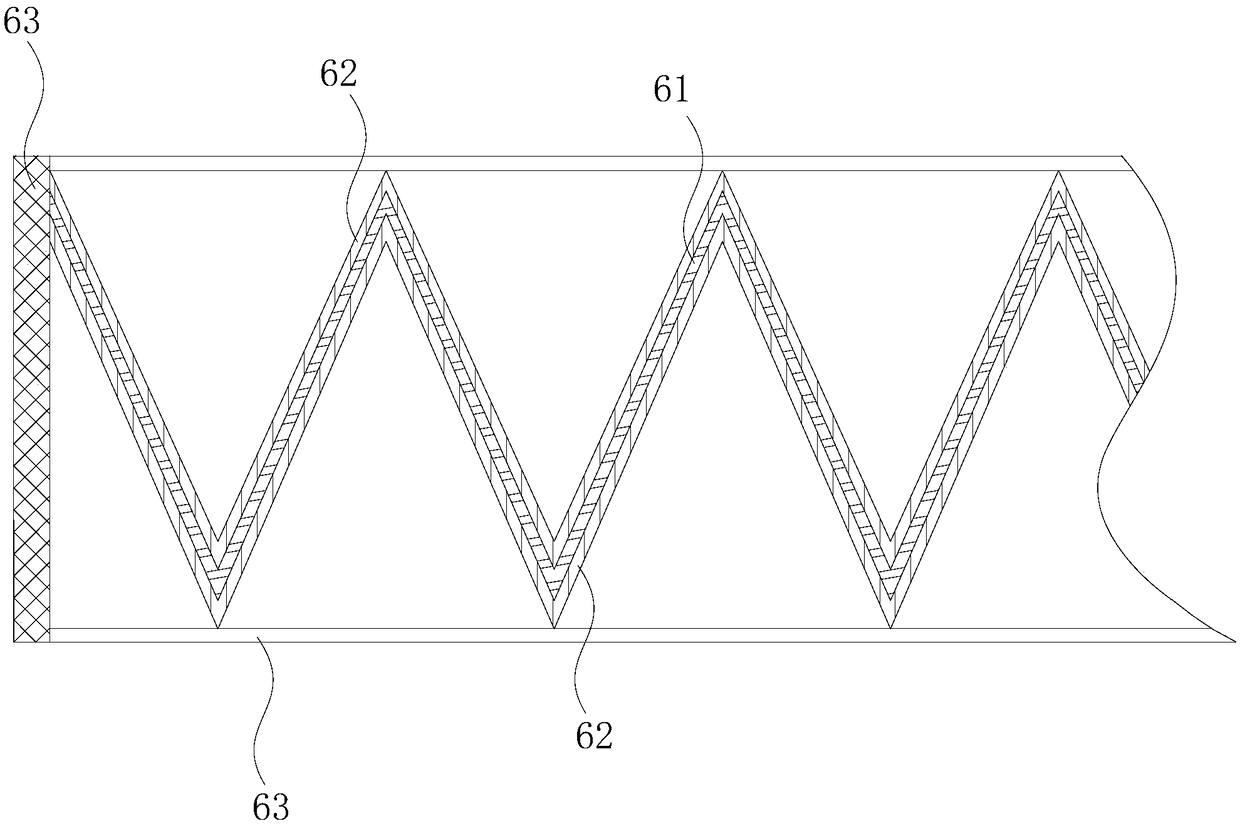

[0036] An oil fume filtering system, comprising an exhaust tube 1, the head end of the exhaust tube 1 is provided with a gas collecting hood 2, the gas collecting hood 2 is located above the stove 9, and the tail end of the exhaust tube 1 is an outer wall discharge end 3 , The oil film device 4, the oil fume separator 5, the modified composite membrane device 6 and the fan 7 are arranged in sequence between the gas collecting hood 2 and the exhaust pipe 1 at the discharge end 3 of the outer wall. In this embodiment, the oil fume separator 5 is a hydrocyclone. The exhaust tube 1 includes two exhaust tubes 11, the head end of each exhaust tube 11 is connected to the gas collecting hood 2, and the tail end of each exhaust tube 11 is connected to the fan 7 , and between the gas collecting hood 2 and the exhaust branch 11 of the fan 7, an oil film device 4, an oil fume separator 5 and a modified composite membrane device 6 are arranged in sequence.

[0037] Preparation of oil film...

Embodiment 2

[0047] An oil fume filtering system, comprising an exhaust tube 1, the head end of the exhaust tube 1 is provided with a gas collecting hood 2, the gas collecting hood 2 is located above the stove 9, and the tail end of the exhaust tube 1 is an outer wall discharge end 3 , The oil film device 4, the oil fume separator 5, the modified composite membrane device 6 and the fan 7 are arranged in sequence between the gas collecting hood 2 and the exhaust pipe 1 at the discharge end 3 of the outer wall. In this embodiment, the oil fume separator 5 is a hydrocyclone. The exhaust tube 1 includes two exhaust tubes 11, the head end of each exhaust tube 11 is connected to the gas collecting hood 2, and the tail end of each exhaust tube 11 is connected to the fan 7 , and between the gas collecting hood 2 and the exhaust branch 11 of the fan 7, an oil film device 4, an oil fume separator 5 and a modified composite membrane device 6 are arranged in sequence.

[0048] Preparation of oil film...

Embodiment 3

[0058] An oil fume filtering system, comprising an exhaust tube 1, the head end of the exhaust tube 1 is provided with a gas collecting hood 2, the gas collecting hood 2 is located above the stove 9, and the tail end of the exhaust tube 1 is an outer wall discharge end 3 , The oil film device 4, the oil fume separator 5, the modified composite membrane device 6 and the fan 7 are arranged in sequence between the gas collecting hood 2 and the exhaust pipe 1 at the discharge end 3 of the outer wall. In this embodiment, the oil fume separator 5 is a hydrocyclone. The exhaust tube 1 includes two exhaust tubes 11, the head end of each exhaust tube 11 is connected to the gas collecting hood 2, and the tail end of each exhaust tube 11 is connected to the fan 7 , and between the gas collecting hood 2 and the exhaust branch 11 of the fan 7, an oil film device 4, an oil fume separator 5 and a modified composite membrane device 6 are arranged in sequence.

[0059] Preparation of oil film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ventilation rate | aaaaa | aaaaa |

| Ventilation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com