Treatment method of radioactive waste negative ion exchange resin

An exchange resin and radioactive waste technology, which is applied in the field of radioactive waste anion exchange resin treatment, can solve the problems of lower oxidant utilization rate, fast oxidant drip rate, large amount of defoamer, etc., and achieve long continuous defoaming time and low price. Inexpensive, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: the selection of reaction system pH

[0059] The ionic state of IRN-78 anion resin is OH - , contacting with aqueous solution can exchange OH - , the pH of the system rises. In the experiment, it was found that 10g of wet IRN-78 anion resin was added to 10mL of water, and after standing still for a period of time, the pH of the resin was greater than 11; at the same time, it was found that during the reaction, as the resin quaternary ammonium ion fell off, the pH would also rise. Therefore, it is necessary to adjust the pH value of the reaction system.

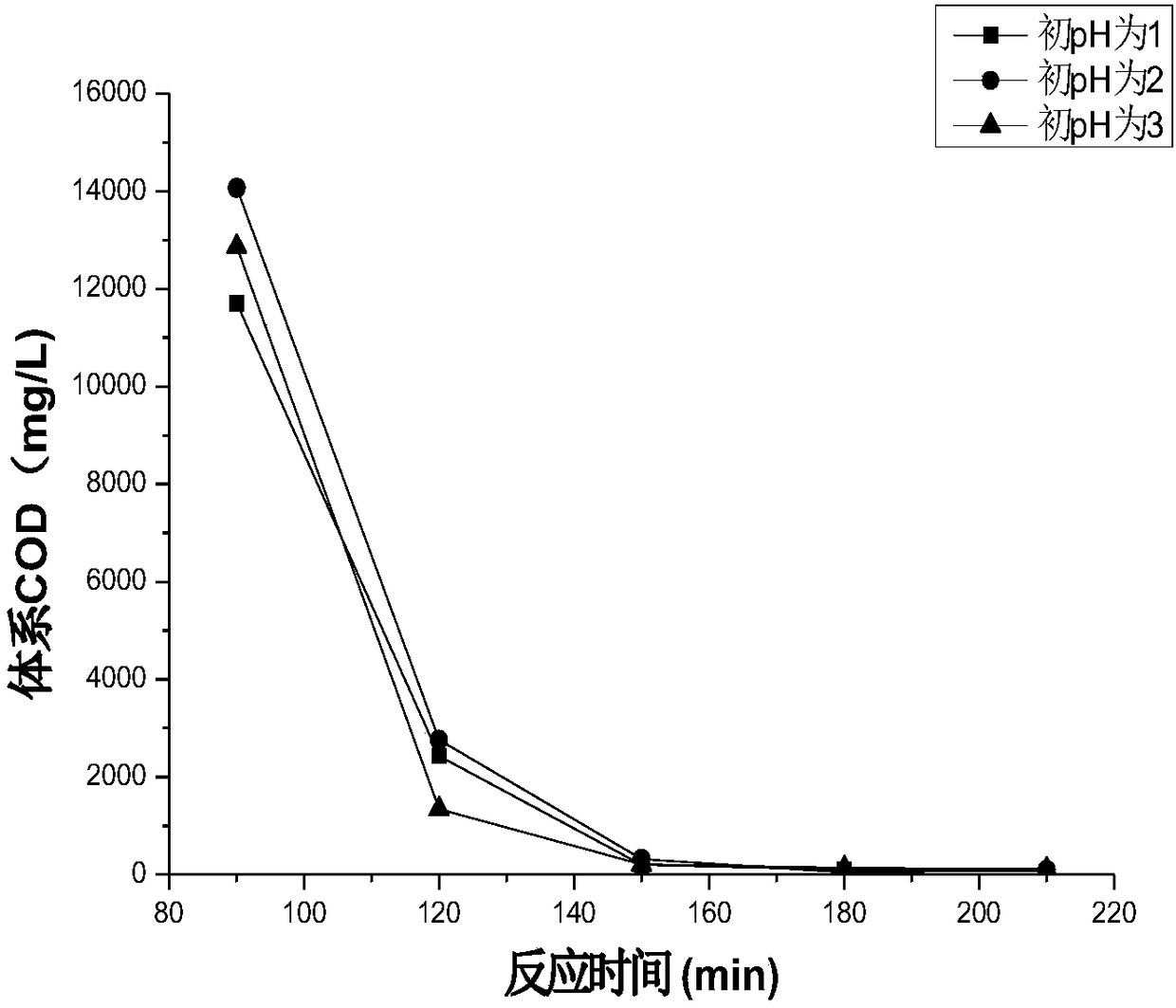

[0060] Such as figure 1 As shown, under the conditions of three different pH values, the variation trend of the residual liquid COD (chemical oxygen demand) in the reaction system is studied. It can be seen that: when the pH is controlled to be 1 and 2, the COD value of the reaction system at the same time point similar; comparatively speaking, the COD value of controlling pH to 3 is smaller. Therefor...

Embodiment 2

[0061] Embodiment 2: the selection of reaction system catalyst

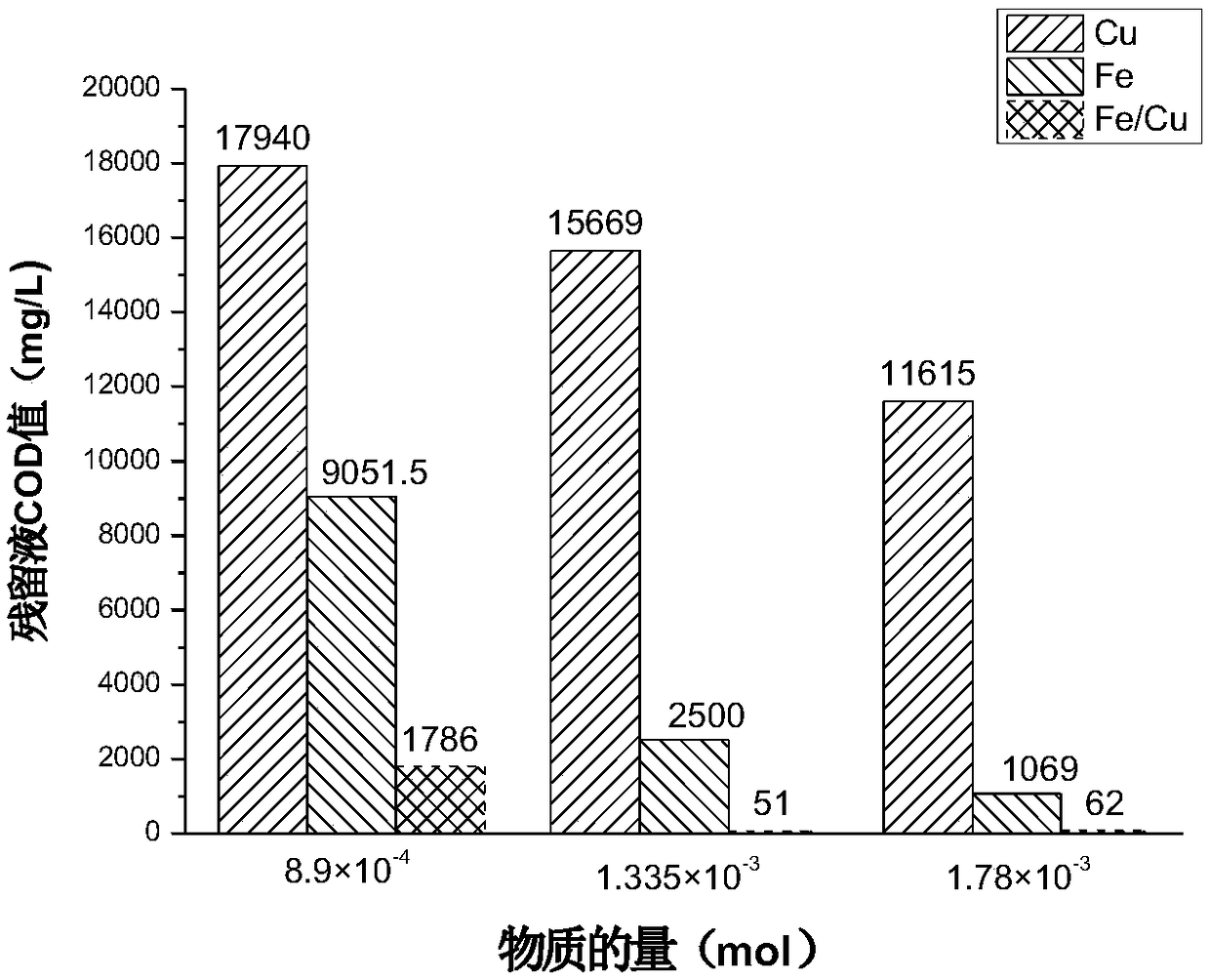

[0062] The selection of catalysts includes the selection of catalyst types and the determination of the molar ratio of mixed catalysts (add sulfuric acid to control the pH of the reaction system to be 2). Depend on figure 2 It can be seen that Fe 2+ with Cu 2+ The catalytic effect of the mixed catalyst is higher than that of Fe 2+ or Cu 2+ The catalytic effect of a single catalyst is obviously better.

Embodiment 3

[0063] Embodiment 3: the selection of reaction system defoamer

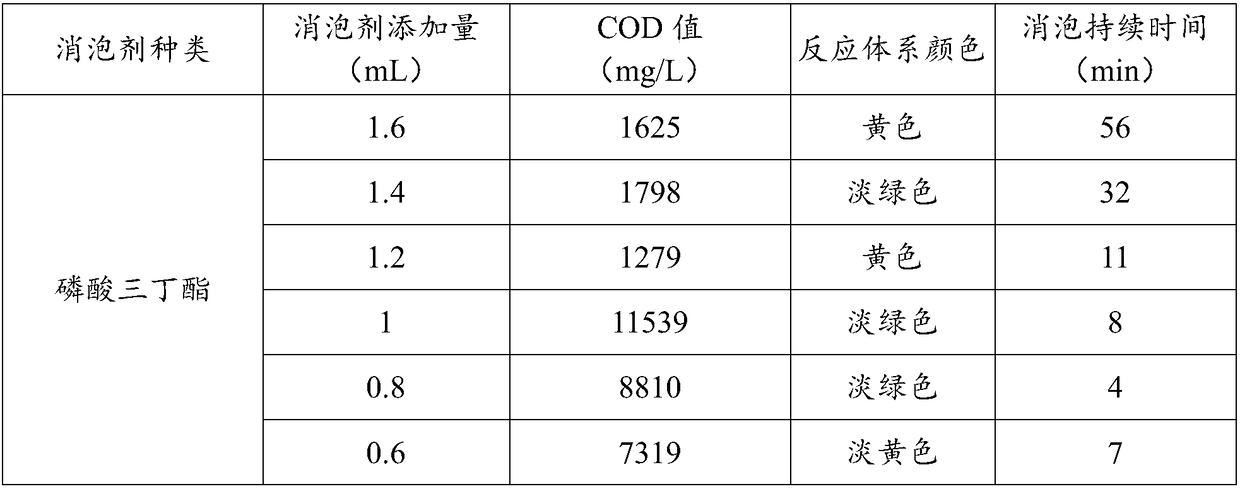

[0064] Select acetic acid, tributyl phosphate and two kinds of organosilicon oil defoamers, totally four kinds of defoamers are carried out defoaming comparative test (add sulfuric acid to control reaction system pH to be 2; adopt Fe 2+ with Cu 2+ Mixed catalyst, the molar ratio of the two is 2:1), during the test, it was found that acetic acid could not eliminate the bubbles, and tributyl phosphate would quickly repeat the foaming. Therefore, the latter three defoamers were selected to carry out single factor experiments (adding sulfuric acid to control the pH of the reaction system was 2; using Fe 2+ with Cu 2+ Mixed catalyst, the molar ratio of the two is 2:1), the results are shown in Table 1.

[0065] It can be seen from Table 1 that compared with tributyl phosphate, silicone oil defoamer has the obvious advantages of less addition and longer defoaming duration. Among them, Dow Corning-3168 defoamer is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com