3D sand mold printing furan resin curing agent and preparing method thereof

A technology of furan resin and curing agent, which is applied in the fields of foundry adhesives and organic chemistry. It can solve the problems of high particle size and uniformity of raw sand, complex processing technology, and impact on equipment life. Effect of uneven atomization and reduction of free sulfuric acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

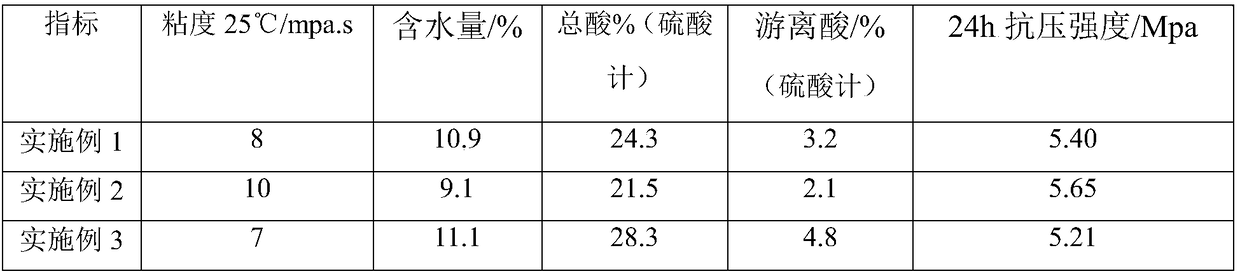

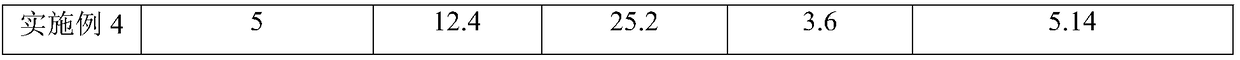

Examples

Embodiment 1

[0027] (1) Throw 100g of toluene and 50g of ethylbenzene in the reactor;

[0028] (2) Add 350g of concentrated sulfuric acid dropwise, control the reaction temperature not to exceed 60°C, and add about 2 hours for about 2 hours;

[0029] (3) Heating up to 110°C and keeping warm for 3 hours under reflux;

[0030] (4) Cool to below 50°C, add dropwise 400g of ethanol, and control the reaction temperature not to exceed 50°C;

[0031] (5) After dropping, add 50g tannic acid, 20g oxalic acid and 30g epoxy emulsion, stir and discharge.

Embodiment 2

[0033] (1) Throw 75g of xylene and 75g of ethylbenzene in the reactor;

[0034] (2) Add 300g of concentrated sulfuric acid dropwise, control the reaction temperature not to exceed 60°C, and add dropwise for about 2 hours;

[0035] (3) Heating up to 115°C and keeping warm for 2 hours under reflux;

[0036] (4) Cool to below 50°C, add dropwise 380g of ethanol, and control the reaction temperature not to exceed 50°C;

[0037] (5) After the dropwise addition, add 40g of tannic acid, 80g of salicylic acid, 30g of hydroxyethyl methacrylate and 20g of aliphatic polyoxyethyl ether, and stir to discharge.

Embodiment 3

[0039] (1) Throw 100g of toluene and 40g of xylene in the reactor;

[0040] (2) 450g of concentrated sulfuric acid was added dropwise, the reaction temperature was controlled not to exceed 60°C, and the dropwise addition time was about 2.5h;

[0041] (3) Heating up to 110°C and keeping warm for 4 hours under reflux;

[0042] (4) Cool to below 50°C, add 300g of ethanol dropwise, and control the reaction temperature not to exceed 50°C;

[0043] (5) After the dropwise addition, add 60g of formic acid, 30g of stearic acid and 20g of vinyl acetate, and stir to discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com