Preparation method of mortar sealing adhesive material

A sealing bonding and mortar technology, which is applied in the field of building materials, can solve problems such as affecting bonding strength, low bonding strength, and inability to withstand long-term heat resistance, and achieves increased compatibility, improved toughening effect, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

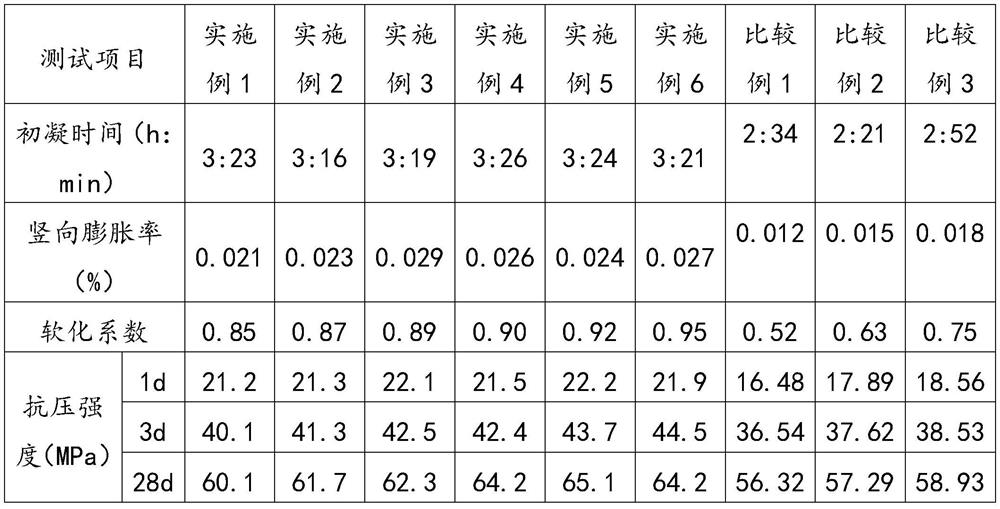

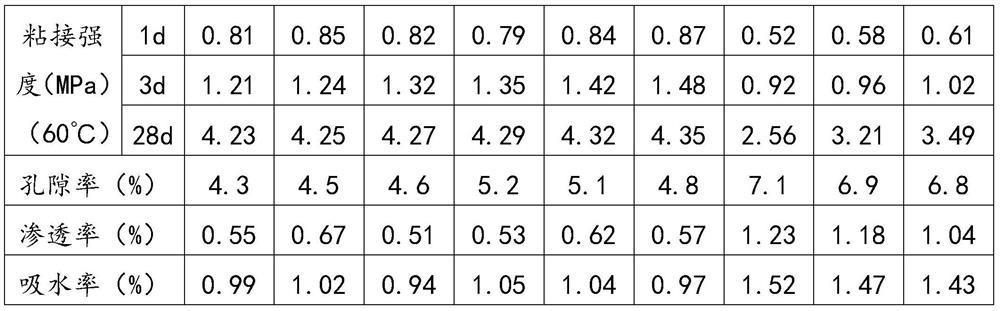

Examples

Embodiment 1

[0030] Step 1: Take 1 weight part of carbon nanotubes and add 20 weight parts of acidic solution (a mixture of concentrated sulfuric acid and concentrated nitric acid, the mixing mass ratio of the two is 3:1), and then add 0.2 weight part of dispersant (polyethylene Diol, molecular weight is 190) ultrasonic dispersion (ultrasonic power is 150KW, and ultrasonic temperature is stabilized at 25 ℃) obtains the acidified chopped carbon nanotube S-CNT-COOH that length is 30nm, then adds 1 weight part of molecular weight and is 80000 Methoxy-PEG-amino, reacted for 30min, and then centrifuged, washed and vacuum freeze-dried to prepare methoxy-PEG-amino modified chopped carbon nanotubes (S-CNT-COOH@MPEG-NH 2 );

[0031] Step 2: Take 50 parts by weight of steel slag, 40 parts by weight of granulated slag, 45 parts by weight of water, 0.01 part by weight of water reducing agent, and 0.6 part by weight of retarder, and mix and wet grind until the median particle size is ≤ 6um , to prepar...

Embodiment 2

[0035]Step 1: Take 3 parts by weight of carbon nanotubes and add 20 parts by weight of an acidic solution (a mixture of concentrated sulfuric acid and concentrated nitric acid, the mixing mass ratio of which is 3:1), and then add 1 part by weight of a dispersant (polyethylene Glycol, molecular weight is 420) ultrasonic dispersion (ultrasonic power is 150KW, and ultrasonic temperature is stable at 25 ℃) obtains the acidified short-cut carbon nanotube S-CNT-COOH that length is 50nm, adds the molecular weight of 0.5 weight part again and is 10000 Methoxy-PEG-amino, reacted for 60min, and then centrifuged, washed and vacuum freeze-dried to prepare methoxy-PEG-amino modified chopped carbon nanotubes (S-CNT-COOH@MPEG-NH 2 );

[0036] Step 2: Take 50 parts by weight of steel slag, 50 parts by weight of granulated slag, 50 parts by weight of water, 0.6 part by weight of water reducing agent, and 0.01 part by weight of retarder, mix and wet grind until the median particle size is ≤ 6um...

Embodiment 3

[0040] Step 1: Take 2 parts by weight of carbon nanotubes and add 20 parts by weight of an acid solution (a mixture of concentrated sulfuric acid and concentrated nitric acid, the mixing mass ratio of which is 3:1), and then add 1 part by weight of a dispersant (polyethylene Glycol, molecular weight is 420) ultrasonic dispersion (ultrasonic power is 150KW, and ultrasonic temperature is stable at 25 ℃) obtains the acidified chopped carbon nanotube S-CNT-COOH that length is 40nm, then adds 2 parts by weight of molecular weight of 10000 Methoxy-PEG-amino, reacted for 60min, and then centrifuged, washed and vacuum freeze-dried to prepare methoxy-PEG-amino modified chopped carbon nanotubes (S-CNT-COOH@MPEG-NH 2 );

[0041] Step 2: Take 60 parts by weight of steel slag, 40 parts by weight of granulated slag, 50 parts by weight of water, 0.6 part by weight of water reducing agent, and 0.01 part by weight of retarder, and mix and wet grind until the median particle size is ≤ 6um , to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com