Grinding technology for ion implantation technology cavity

An ion implantation and grinding process technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of difficulty in meeting the vacuum degree of the process chamber, high vacuum degree requirements, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The present invention is a welding process for an ion implantation process cavity, which includes the following process steps for the weldment in sequence: 1. Pretreatment of the weldment before welding; 2. Welding the cavity weldment by gas shielded welding; 3. 1. Treatment of the weldment after welding; the shielding gas used in step 2 is a mixture of argon and hydrogen; in the process of welding the weldment into a cavity in step 2, spot welding is used on the atmospheric side of the cavity. The solder joints on the atmospheric side of the cavity are strip-shaped, and the distance between adjacent solder joints is less than the length of the solder joints. In step 1, use acetone to clean the groove of the weldment and the dirt within 30-50mm from both sides of the groove, and preheat the vacuum chamber to 10°C to ensure a uniform preheating temperature. In step 2, the welding line energy is controlled at 20-25kJ / cm, the welding wire is ER316L, the diameter of the wel...

Embodiment 2

[0018] The only difference from Example 1 is that the electrolyte is a mixed solution composed of 70% by mass of phosphoric acid, 20% of sulfuric acid and 10% of hydrofluoric acid. The mass ratios of argon and hydrogen in the mixed gas are 90% and 10% respectively. Preheat the vacuum chamber to 250°C to ensure uniform preheating temperature.

Embodiment 3

[0020] The only difference from Example 1 is that the electrolyte is a mixed solution composed of 69% phosphoric acid, 28% sulfuric acid and 3% hydrofluoric acid. The mass ratios of argon and hydrogen in the mixed gas are 99.99% and 0.01% respectively; the vacuum chamber is preheated to 100°C to ensure uniform preheating temperature.

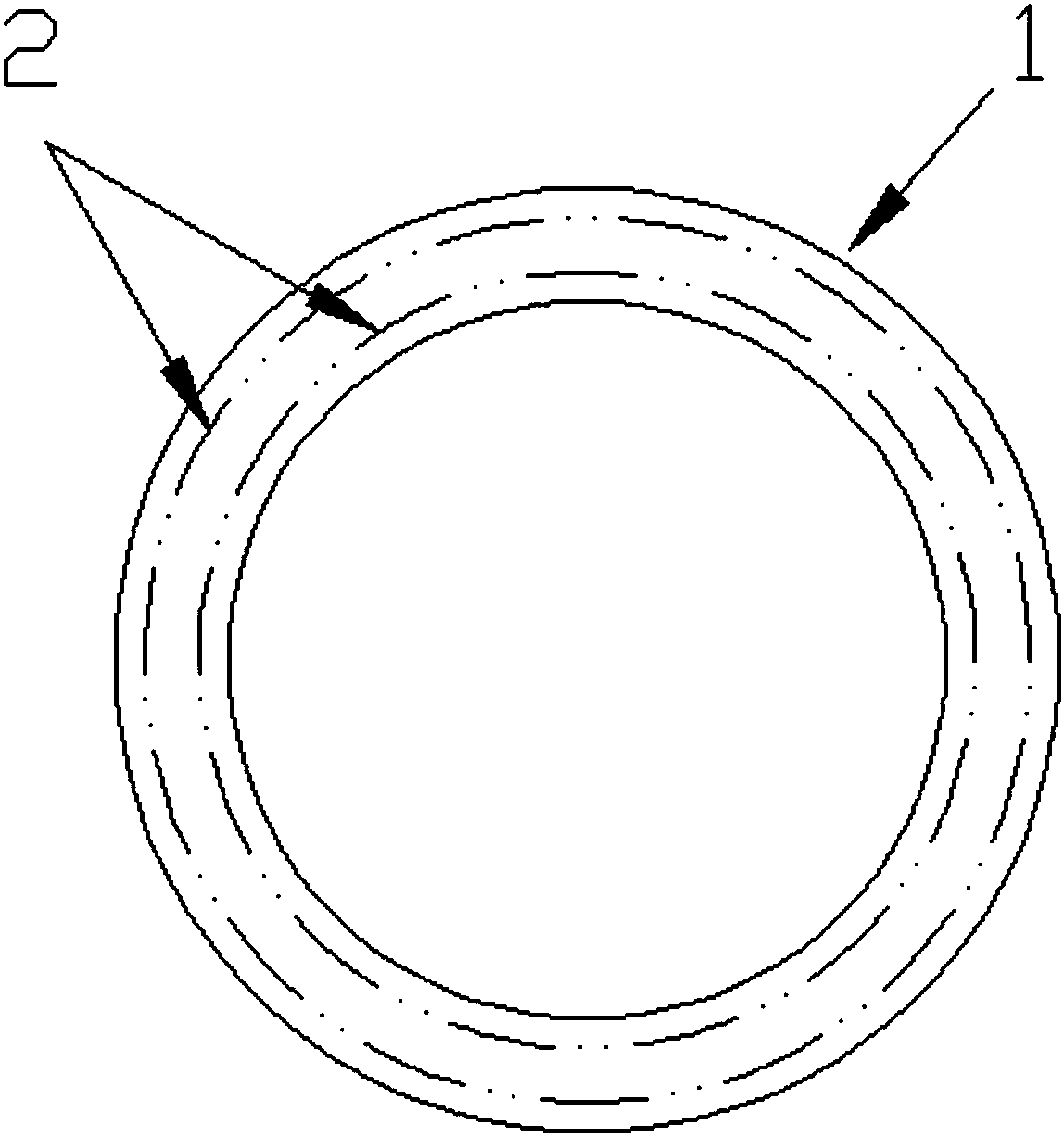

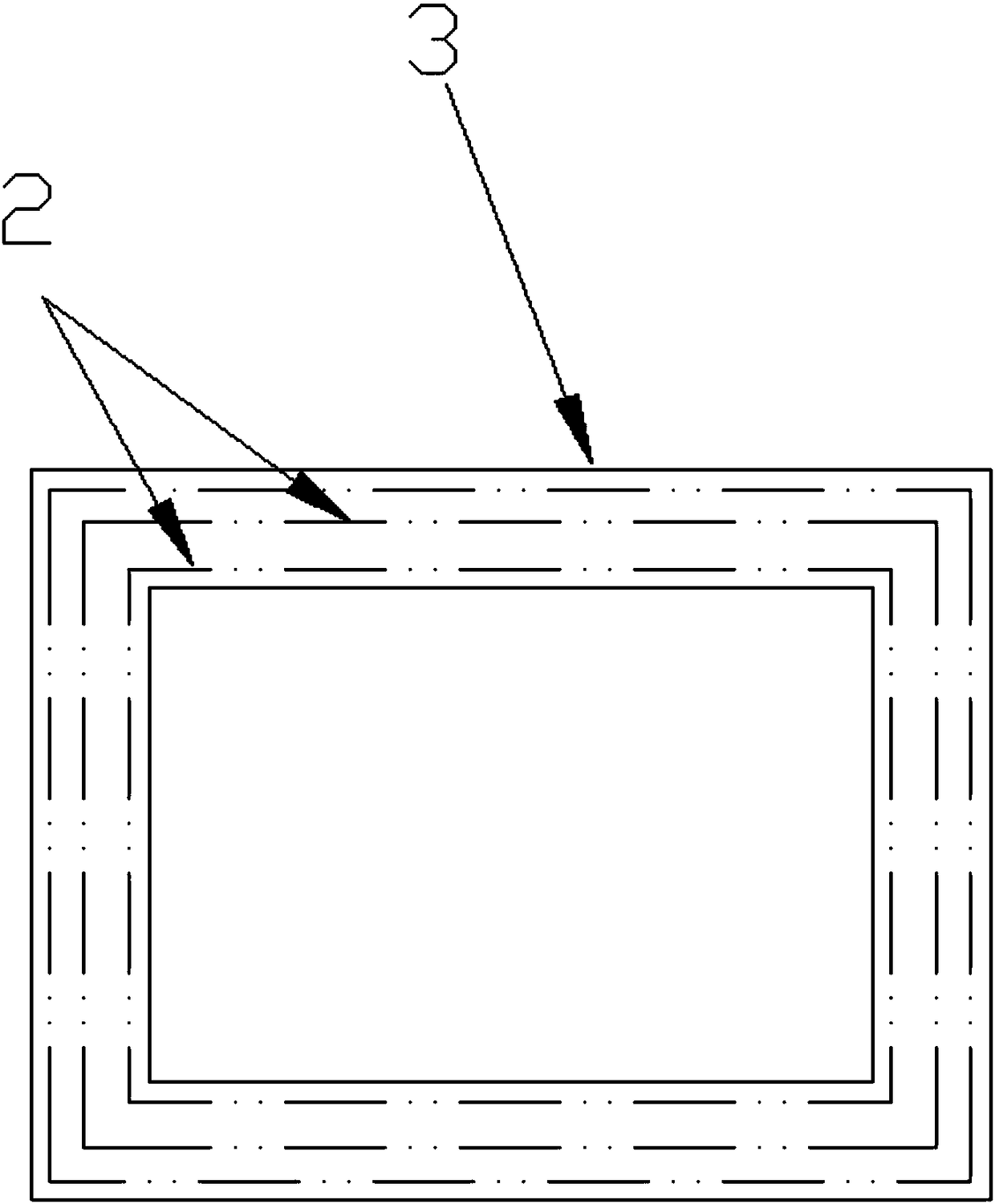

[0021] Such as figure 1 , figure 2 As shown, the schematic diagram of the ground surface texture 2 of the flange surface 1 and the sealing groove 3 after being processed by this process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com