Magnesium dioxide/carbon black composite material and preparation method and application thereof

A composite material, manganese dioxide technology, applied in fuel cell type half cells and primary cell type half cells, electrical components, battery electrodes, etc., can solve the problems of complex devices, high energy consumption, and unsuitable for industrial production. , to achieve the effect of simple device, low energy consumption and stable synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

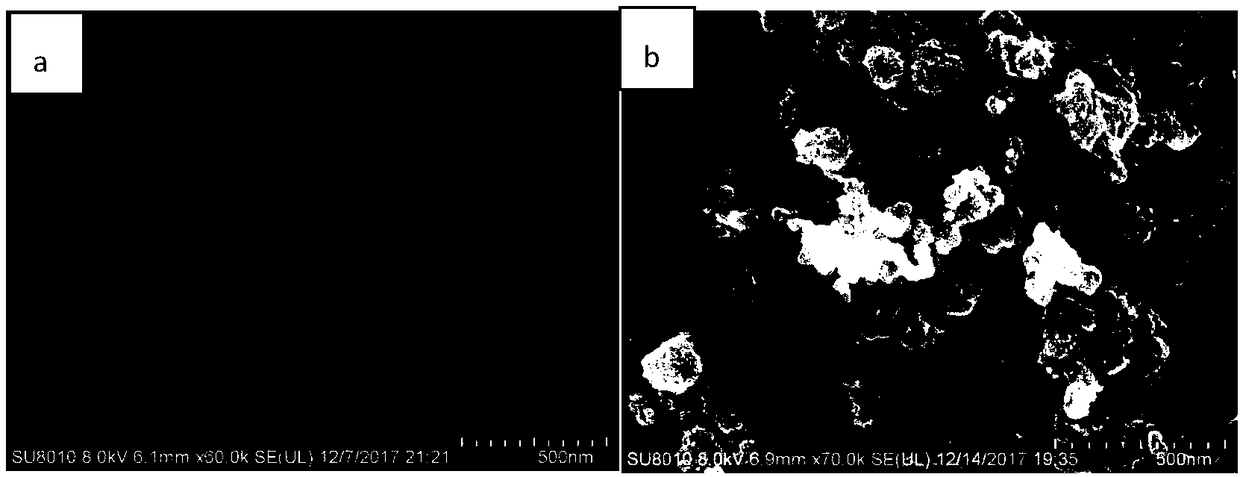

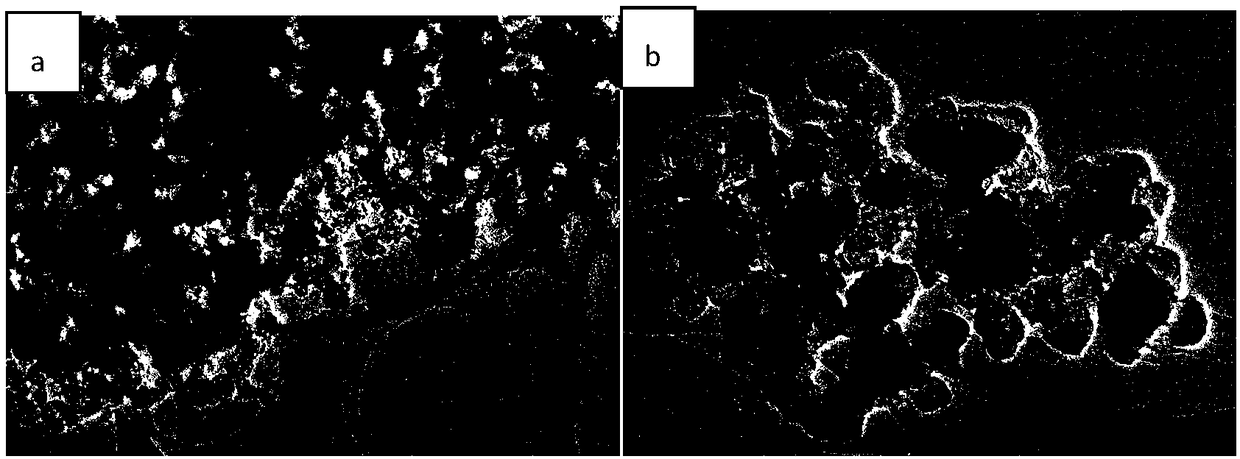

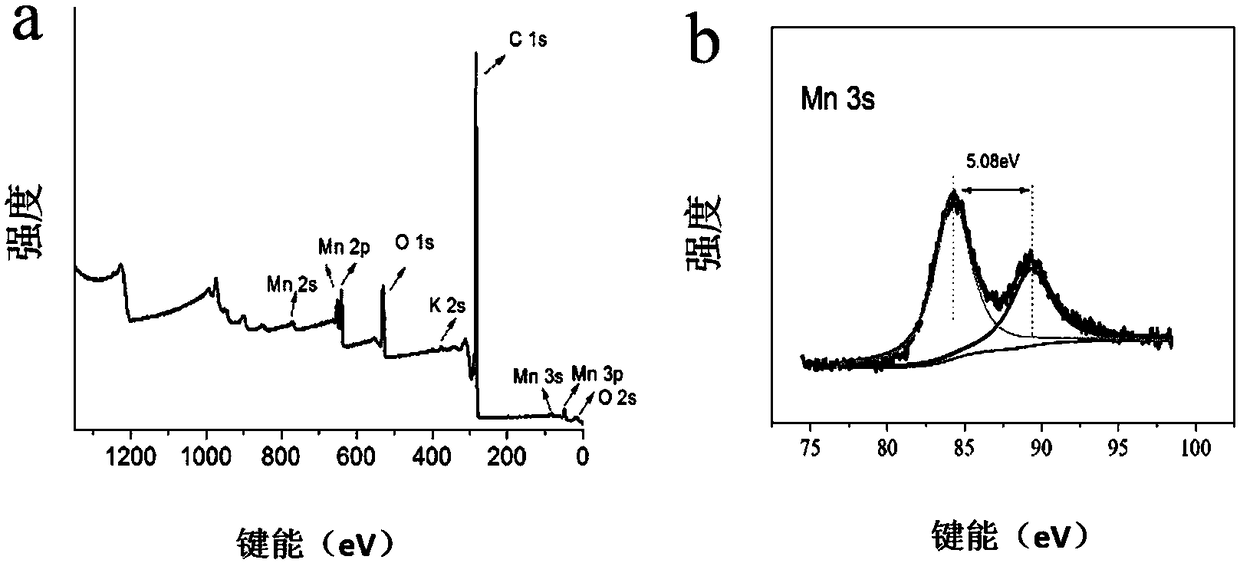

[0037] Add 5 g of acetylene carbon black into a glass bottle with 1000 mL of deionized water, stir to obtain a 5 mg / mL dispersed carbon black solution; slowly add 1000 mL of potassium permanganate solution with a concentration of 0.1 mol / L to the resulting dispersion, Stir for 10 minutes to obtain a homogeneous mixture; place the obtained mixed solution in a water bath at 85°C, heat it and ultrasonically (ultrasonic power: 800W) for 3 hours; repeatedly suction-filter and wash the obtained solution with deionized water for 3 to 5 times, and finally dry at 120°C The manganese dioxide / carbon black composite material was obtained in 8 hours.

Embodiment 2

[0039] Add 1 g of acetylene black into a flask filled with 200 mL of deionized water, and stir to obtain a 5 mg / mL dispersion; slowly add 200 mL of potassium permanganate solution with a concentration of 0.05 mol / L to the obtained dispersion, and stir for 10 minutes to obtain a uniform The mixture; the resulting mixed solution was placed in a water bath at 80° C., heated and ultrasonically (ultrasonic power: 300 W) for 5 hours; the resulting solution was repeatedly suction-filtered and washed 3 to 5 times with deionized water, and finally dried at 100° C. for 8 hours. A manganese dioxide / carbon black composite material is obtained.

Embodiment 3

[0041] Add 0.1g of Ketjen Black EC-300J conductive carbon black into a flask containing 200mL of deionized water, stir to obtain a 0.5mg / mL dispersion solution; slowly add 200mL of high concentration 0.01mol / L to the resulting dispersion Lithium manganate solution, stirred for 10 minutes to obtain a homogeneous mixture; placed the obtained mixed solution in a water bath at 90°C, heated and ultrasonicated (ultrasonic power: 2400W) for 30 minutes; repeatedly suction-filtered and washed the obtained solution with deionized water for 3 to 5 times, Finally, dry at 80° C. for 12 hours to obtain a manganese dioxide / carbon black composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com