High-activity hydro-cracking preprocessing catalyst and preparing method and application thereof

A hydrocracking and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems of reducing catalyst reactivity, aggregation of active metal components, uneven metal distribution, etc., to achieve shortening The effect of drying activation time, reducing production cost, and improving drying activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

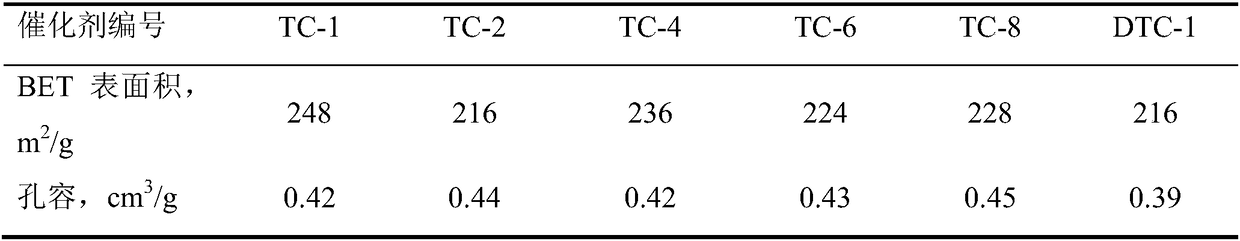

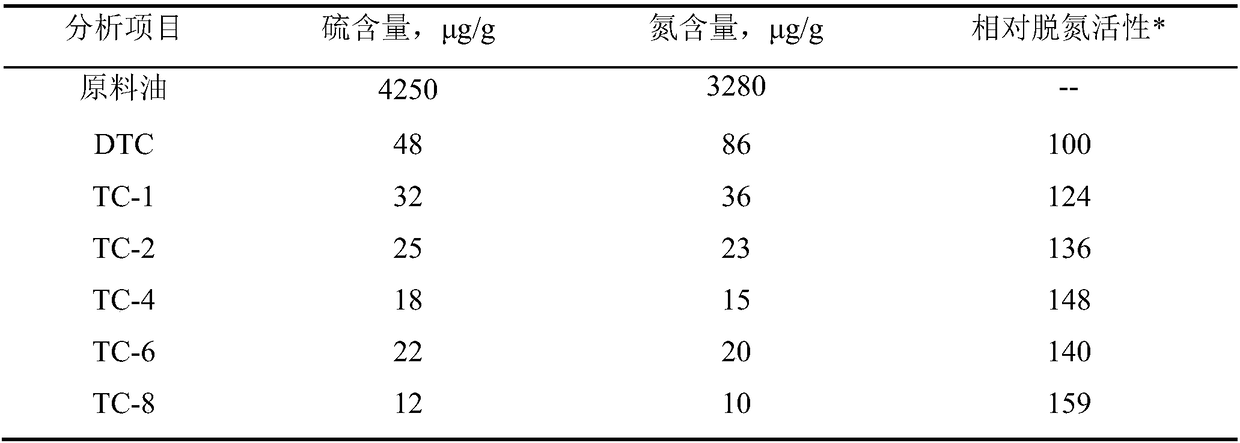

[0033] Catalyst design: NiO:4.0wt%, MoO 3 :4.0wt%, WO 3 : 20.0wt%, P 2 o 5 : 2.0wt%, silicon modified alumina 28.0wt%, modified USY molecular sieve 12.0wt%, macroporous alumina 30.0wt%.

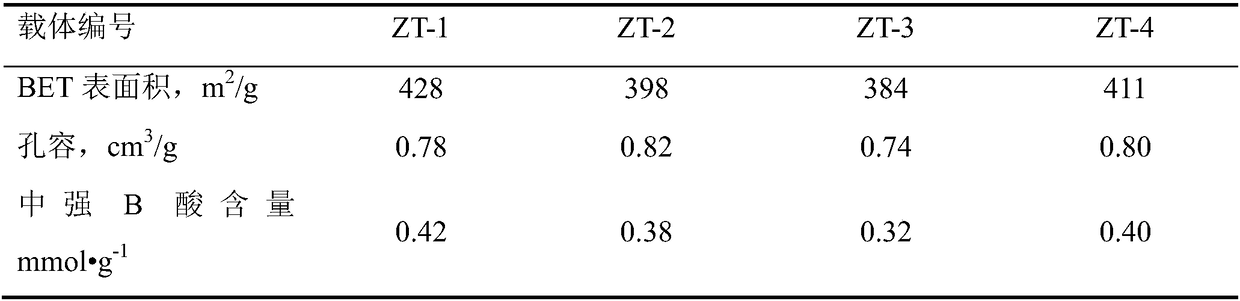

[0034] 238.0g macroporous alumina (dry basis content 72%), 222.0g silicon modified alumina (SiO 2 Content 4wt%, dry basis content 74%), 78.0g modified Y molecular sieve (SiO 2 / Al 2 o 3 =25.0, dry basis content 88%) mixed with 8.0g methyl cellulose, put into kneader and knead for 20min, add 500g of acidic solution prepared by water, acetic acid, citric acid into dry powder successively, first knead until extrudable paste The material is then extruded once through an empty plate and a cylindrical orifice plate with a diameter of 8 mm, and finally formed into a butterfly-shaped bar with a diameter of 1.5 mm; the obtained wet bar is dried in an oven at 120 ° C for 8 hours, and finally placed in a muffle furnace The temperature was programmed to rise to 500°C for 3 hours to obtain the carr...

Embodiment -2

[0037] Catalyst design: NiO:4.0wt%, MoO 3 :4.0wt%, WO 3 : 20.0wt%, P 2 o 5 : 2.0wt%, silicon-zirconium modified alumina 24.0wt%, H-Beta molecular sieve 14.0wt%, macroporous alumina 32.0wt%.

[0038] 256.0g macroporous alumina (dry basis content 72%), 183.0g silicon zirconium modified alumina (SiO 2 , ZrO 2 Total content 8wt%, dry basis content 75%), 94.0g H-Beta molecular sieve (SiO 2 / Al 2 o 3 =40.0, dry basis content 85%), 8.0g kale powder mixed with 4.0g methyl cellulose and then dropped into a kneader for 20min mixing, and 490g was added successively in the dry powder by the acidic solution prepared by water, acetic acid and citric acid. Knead until extrudable paste, then extrude through an empty plate and a cylindrical orifice plate with a diameter of 8 mm, and finally form a butterfly-shaped bar with a diameter of 1.5 mm; dry the obtained wet bar in an oven at 120 ° C for 8 hours, and finally Place in a muffle furnace and heat up to 500°C for 3 hours to obtain th...

Embodiment -3

[0041] Catalyst design: NiO:4.0wt%, MoO 3 :4.0wt%, WO 3 : 20.0wt%, P 2 o 5 : 2.0wt%, silicon phosphorus modified alumina 28.0wt%, H-SAPO-5 molecular sieve 14.0wt%, macroporous alumina 28.0wt%.

[0042] 222.0g macroporous alumina (dry basis content 72%), 222.0g silicon phosphorus modified alumina (SiO 2 ,P 2 o 5 Total content 6wt%, dry basis content 72%), 89.0g H-Beta molecular sieve (SiO 2 / Al 2 o 3 = 0.3, dry basis content 90%), 8.0g kale powder and 4.0g soluble starch are mixed and put into a kneader for 20min. The acid solution prepared by water, acetic acid and citric acid is added to the dry powder successively by 490g, and first kneaded to The extrudable paste is extruded through a toothed spherical orifice, stretched and broken by a belt transmission device, and finally pelletized to obtain a toothed spherical carrier with a particle size of 2.0mm; the obtained wet ball is dried in an oven at 120°C for 6 hours , and finally placed in a muffle furnace and progra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com