Fly ash grouting material and preparation method thereof

A technology for grouting material and fly ash, which is applied in the field of grouting material and its preparation, can solve the problems of high energy consumption for raw material acquisition, long setting time, low solidification rate, etc. , the effect of fast hydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

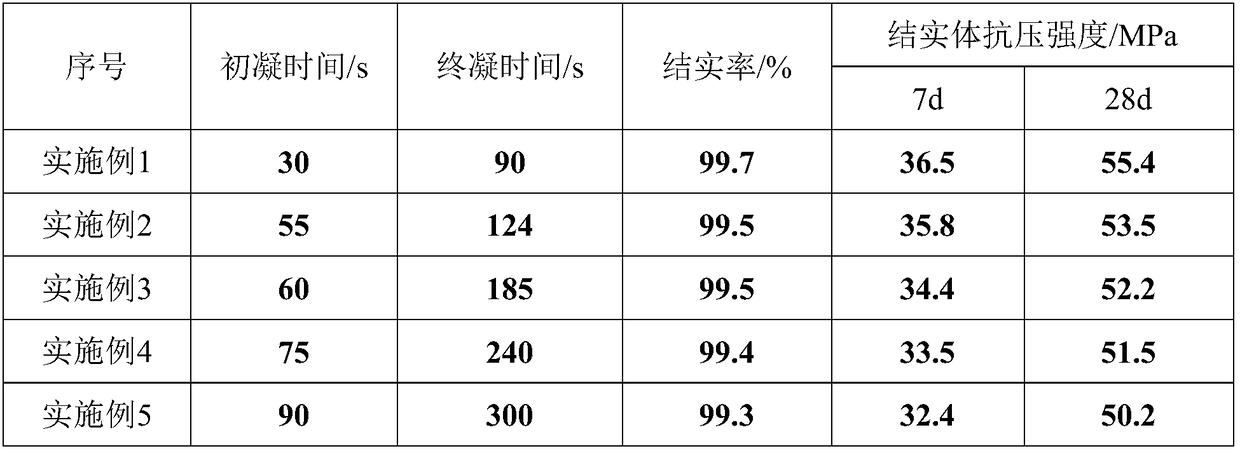

Examples

Embodiment 1

[0065] A preparation method of fly ash grouting material, comprising the steps of:

[0066] (1) Preparation of component A: Take by weighing 50 parts of fly ash, 15 parts of ammonium dihydrogen phosphate, 10 parts of potassium dihydrogen phosphate, and 2 parts of pH regulator (component ratio is: 30 parts of disodium hydrogen phosphate , 70 parts of dipotassium hydrogen phosphate), 1 part of organosilicon defoamer, 0.04 part of basalt fiber, mix and stir evenly for later use;

[0067] (2) Preparation of component B: take 10 parts of magnesium oxide in proportion (component distribution ratio is: 60 parts of heavy light burned magnesium, 40 parts of light light burned magnesium), 2 parts of polymer emulsion (component distribution ratio is : 50 parts of polyacrylic acid, 50 parts of polyvinyl acetate, the solid content of the emulsion is 42%), 0.5 part of polycarboxylate ammonium salt dispersant (solid content is 26%), 1 part of retarder (component distribution ratio is: three ...

Embodiment 2

[0070] A preparation method of fly ash grouting material, comprising the steps of:

[0071] (1) Preparation of Component A: Weigh 100 parts of fly ash, 10 parts of ammonium dihydrogen phosphate, 5 parts of potassium dihydrogen phosphate, and 1.5 parts of pH regulator (the component distribution ratio is: 40 parts of disodium hydrogen phosphate, 60 parts of dipotassium hydrogen phosphate), 0.7 part of organosilicon defoamer, 0.03 part of basalt fiber, mix, stir well and set aside;

[0072] (2) Preparation of component B: Weigh 20 parts of magnesium oxide in proportion (the component distribution ratio is: 70 parts of heavy light burned magnesium, 30 parts of light light burned magnesium), 2 parts of polymer emulsion (the component distribution ratio is: 40 parts of polyacrylic acid, 60 parts of polyvinyl acetate, the solid content of the emulsion is 45%), 0.2 part of polycarboxylate ammonium salt dispersant (solid content is 27%), 2 parts of retarder (component distribution rat...

Embodiment 3

[0075] A preparation method of fly ash grouting material, comprising the steps of:

[0076] (1) Preparation of component A: Take 100 parts of fly ash in proportion, 5 parts of ammonium dihydrogen phosphate, 10 parts of potassium dihydrogen phosphate, and 1 part of pH regulator (the component distribution ratio is: 20 parts of disodium hydrogen phosphate, 80 parts of dipotassium hydrogen phosphate), 1 part of organosilicon defoamer, 0.04 part of basalt fiber, mixed, stirred evenly and set aside.

[0077] (2) Preparation of component B: Weigh 30 parts of magnesium oxide in proportion (component distribution ratio is: 80 parts of heavy light burnt magnesium, 20 parts of light light burnt magnesium), 3 parts of polymer emulsion (component distribution ratio is: 40 parts of polyacrylic acid, 60 parts of polyvinyl acetate, the solid content of the emulsion is 52%), 0.4 part of polycarboxylate ammonium salt dispersant (solid content is 26%), 5 parts of retarder (the component distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com