Heat conducting and storing graphene sizing phase-change material and preparation method thereof

A phase-change material, graphene technology, applied in the field of thermally conductive materials, can solve problems such as strong safety, low thermal conductivity, energy storage, and lower temperature of electronic products, and achieve the effect of flexible application form and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

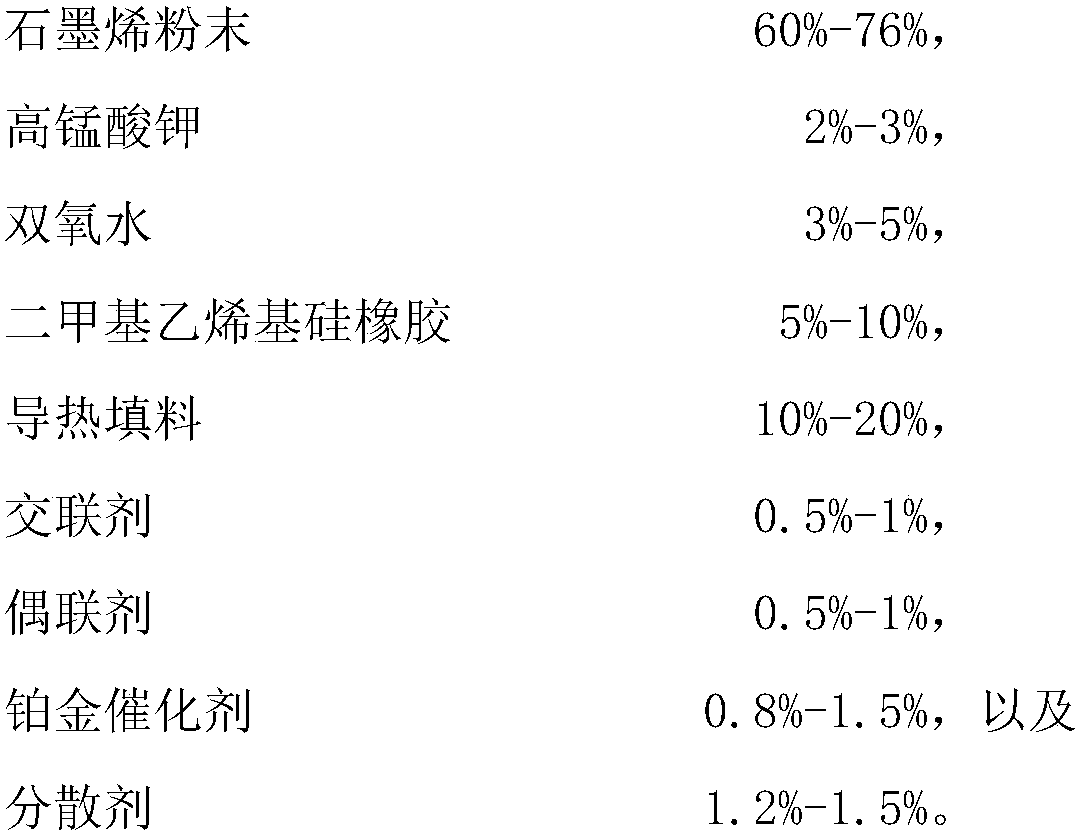

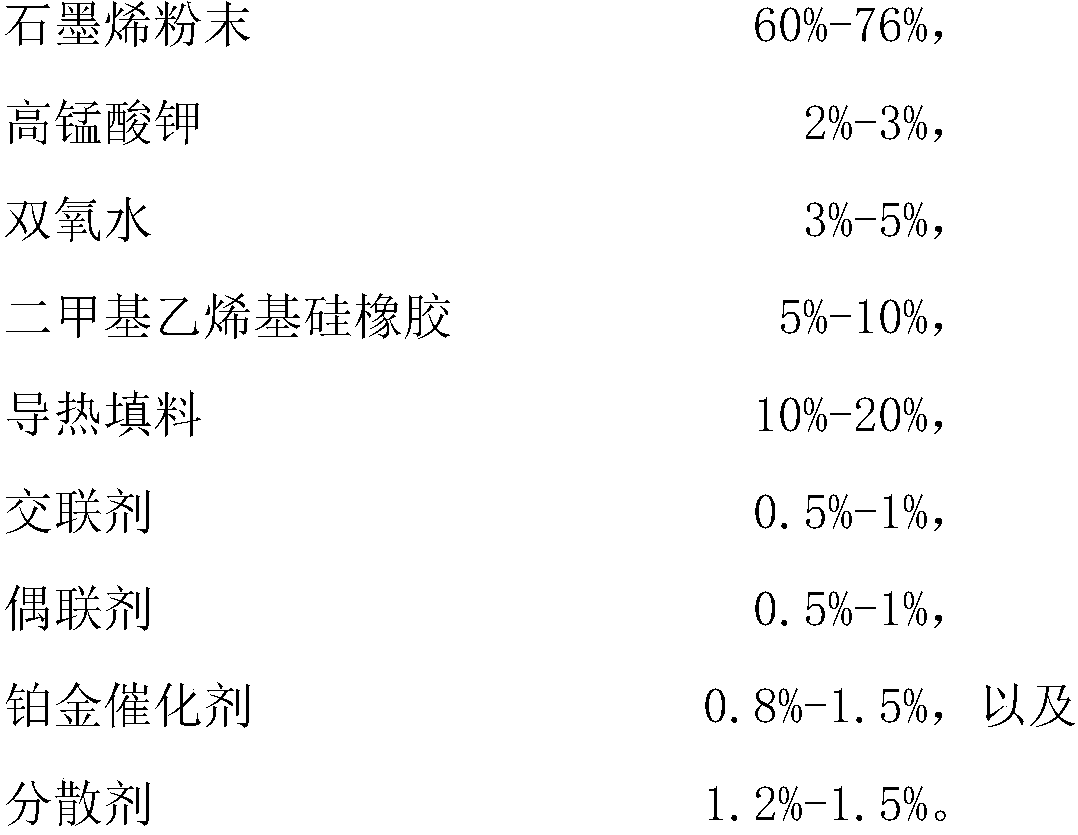

[0035] This embodiment provides a preparation process of a heat conduction heat storage graphene shaped phase change material, including the following process steps:

[0036] Step 1): Add 66g of graphene powder into a reactor equipped with deionized water, ultrasonically stir to make it evenly dispersed, and configure it into a graphene solution;

[0037] Step 2): the reactor is placed in an ice-water bath, and adding mass concentration to the reactor is 98% H 2 SO 4 , and potassium nitrate solution, stirred until completely dissolved, and kept at 85°C for 15 minutes;

[0038] Step 3): Then add 2.5 g of potassium permanganate with a particle size below the micron level, and then stir the reactor at slightly higher than normal temperature (25-35° C.) for 3 hours;

[0039] Step 4): Take out the reactor, cool it down, then add 3g of hydrogen peroxide dropwise under the condition of uninterrupted stirring, and separate the layers after standing for 8h;

[0040]Step 5): Pour off...

Embodiment 2

[0044] This embodiment provides a preparation process of a heat conduction heat storage graphene shaped phase change material, including the following process steps:

[0045] Step 1): Add 70g of graphene powder into a reactor equipped with deionized water, ultrasonically stir to make it evenly dispersed, and configure it into a graphene solution;

[0046] Step 2): the reactor is placed in an ice-water bath, and adding mass concentration to the reactor is 98% H 2 SO 4 , and sodium nitrate solution, stirred until completely dissolved, and kept at 90°C for 20 minutes;

[0047] Step 3): Then add 3 g of potassium permanganate with a particle size below the micron level, and then stir the reactor at slightly higher than normal temperature (25-35° C.) for 3.5 hours;

[0048] Step 4): Take out the reactor, cool it down, and then add 4.8g of hydrogen peroxide dropwise under continuous stirring, and let it stand for 8 hours to separate layers;

[0049] Step 5): Pour off the upper lay...

Embodiment 3

[0053] This embodiment provides a preparation process of a heat conduction heat storage graphene shaped phase change material, including the following process steps:

[0054] Step 1): Add 64g of graphene powder into a reactor equipped with deionized water, ultrasonically stir to make it evenly dispersed, and configure graphene solution;

[0055] Step 2): the reactor is placed in an ice-water bath, and adding mass concentration to the reactor is 98% H 2 SO 4 , and sodium sulfate solution, stirred until completely dissolved, and kept at 88°C for 18 minutes;

[0056] Step 3): Then add 3 g of potassium permanganate with a particle size below the micron level, and then stir the reactor at a temperature slightly higher than normal temperature (25-35°C) for 4 hours;

[0057] Step 4): Take out the reactor, cool it down, and then add 4.8g of hydrogen peroxide dropwise under continuous stirring, and let it stand for 8 hours to separate layers;

[0058] Step 5): Pour off the upper lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com