Energy-saving type soft alloy atomic state oil film lubricating oil additive

A lubricating oil additive and energy-saving technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve problems such as dry friction or semi-dry friction of equipment, inability to self-repair and protection, and inability to form a lubricating oil film, etc., to achieve Good self-repair and maintenance effect, excellent lubricating auxiliary effect, and extended working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

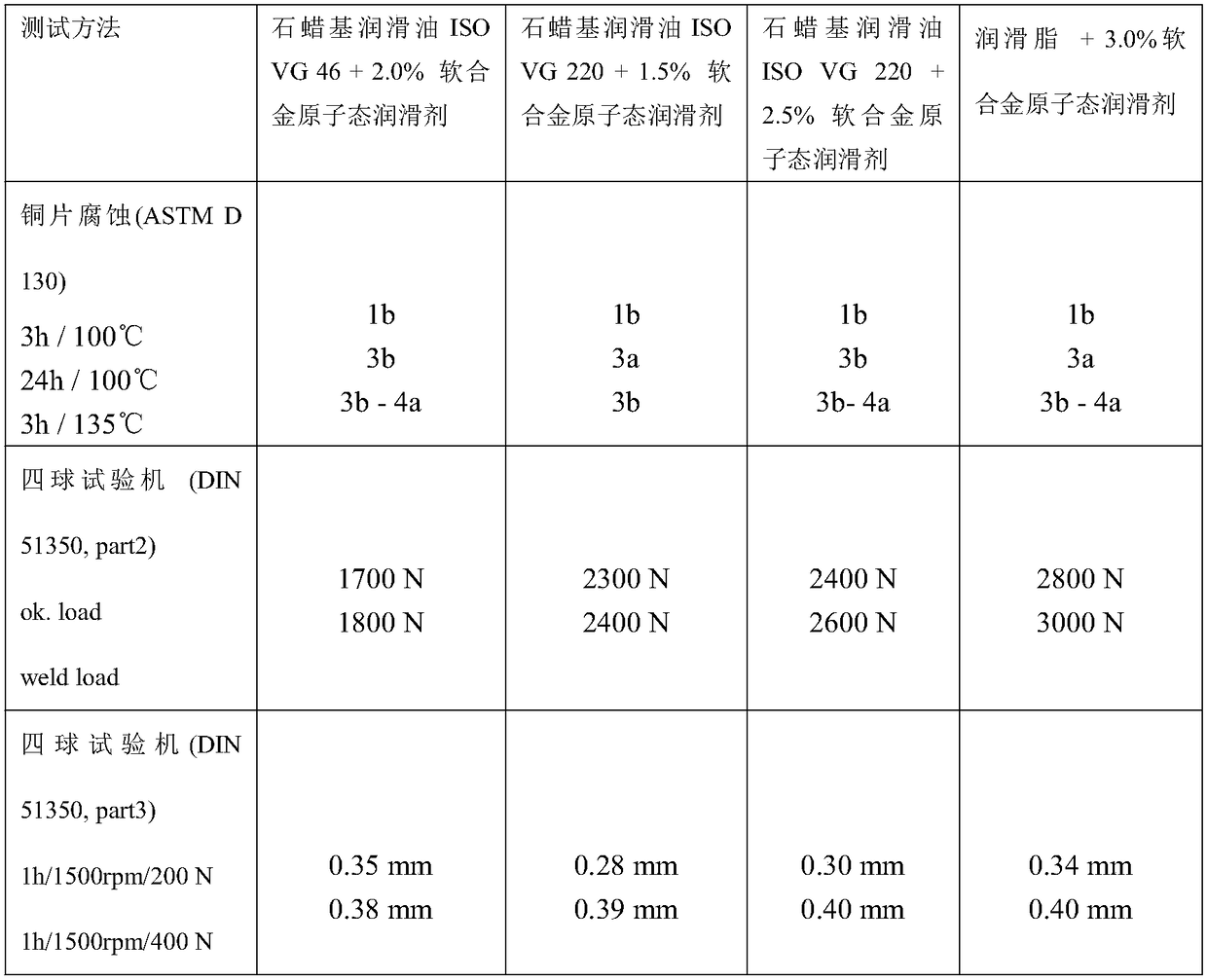

[0029] An energy-saving soft alloy atomic state oil film lubricant additive, characterized in that: it is composed of soft alloy, neodymium iron boron, and basic lubricant, and the soft alloy includes copper Cu, nickel Ni, titanium Ti nano-scale spherical particles , wherein the particles with a particle size of 40-50nm account for 50% by weight, the particles with a particle size of 20-40nm account for 40%, and the particles with a particle size of 50-100nm account for 10%.

[0030] The percentage content of each component in the lubricating oil additive is: soft alloy 5wt%, neodymium iron boron 6wt%, and the balance of basic lubricant. The lubricating oil additive also includes 3wt% of hexamethyldisilazane and 5wt% of fumed white carbon black.

[0031] The soft alloy also includes nano-borate, which accounts for 10% of the total mass of the soft alloy, and the nano-borate is a composition of nano-magnesium borate whiskers and nano-molybdenum borate.

[0032] The base lubric...

Embodiment 2

[0035] An energy-saving soft alloy atomic state oil film lubricant additive, characterized in that: it is composed of soft alloy, neodymium iron boron, and basic lubricant, and the soft alloy includes copper Cu, nickel Ni, titanium Ti nano-scale spherical particles , the proportion of particles with a particle diameter of 40-50nm is 60wt%, the proportion of particles with a particle diameter of 20-40nm is 20%, and the proportion of particles with a particle diameter of 50-100nm is 20%.

[0036] The percentage content of each component in the lubricating oil additive is: soft alloy 10wt%, neodymium iron boron 5wt%, and the balance of basic lubricant. The lubricating oil additive also includes 2wt% of hexamethyldisilazane and 4wt% of fumed white carbon black.

[0037] The soft alloy also includes nano borate, which accounts for 10% of the total mass of the soft alloy, and the nano borate is a composition of nano aluminum borate whiskers and nano magnesium borate whiskers.

[0038...

Embodiment 3

[0041] An energy-saving soft alloy atomic state oil film lubricant additive, characterized in that: it is composed of soft alloy, neodymium iron boron, and basic lubricant, and the soft alloy includes copper Cu, nickel Ni, titanium Ti nano-scale spherical particles , the proportion of particles with a particle diameter of 40-50nm is 30wt%, the proportion of particles with a particle diameter of 20-40nm is 50%, and the proportion of particles with a particle diameter of 50-100nm is 20%.

[0042] The percentage content of each component in the lubricating oil additive is: soft alloy 10wt%, neodymium iron boron 3wt%, and the balance of basic lubricant. The lubricating oil additive also includes 4wt% of hexamethyldisilazane and 2.5wt% of fumed white carbon black.

[0043] The soft alloy also includes nano-borate, which accounts for 8% of the total mass of the soft alloy. Nano-borate is a combination of nano-aluminum borate whiskers, nano-magnesium borate whiskers, nano-molybdenum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com