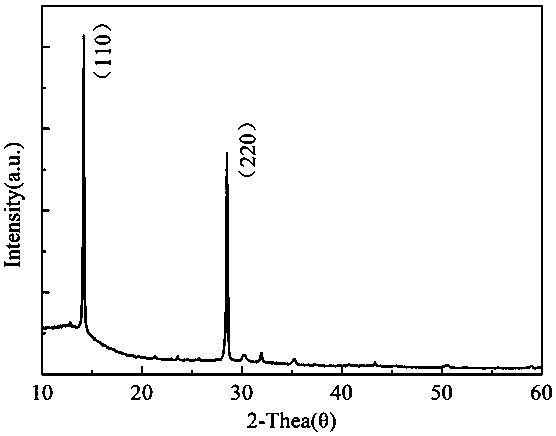

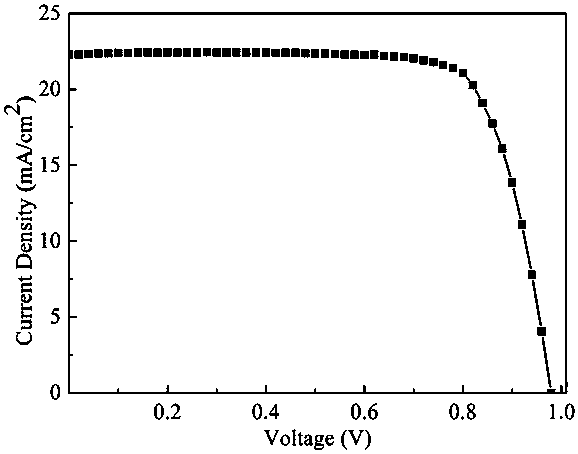

Preparation method for Perovskite-MoS2 bulk heterojunction type perovskite solar cell

A solar cell and bulk heterojunction technology, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems affecting the effective transport of photogenerated carriers and the inappropriate energy level matching of the hole transport layer. The effect of good photoelectric conversion efficiency, promotion of extraction and transmission, and good photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step S100: preparing a PEDOT:PSS hole transport layer, the specific steps are:

[0036] Step S101: Place the cleaned and dried ITO glass on a homogenizer, uniformly coat the PEDOT:PSS aqueous solution on the ITO glass with a pipette gun and perform spin coating to obtain the precursor film of the PEDOT:PSS hole transport layer, spin coating The rotating speed is 2000 rpm, and the spin coating time is 50 seconds;

[0037] Step S102: Place the ITO substrate of the spin-coated precursor film treated in step S101 on a heating table, and continue annealing at 120° C. for 15 minutes in an air environment to obtain a PEDOT:PSS hole transport layer with uniform thickness;

[0038] Step S200: Prepare MoS 2 The buffer layer, the specific steps are:

[0039] Step S201: black powder MoS 2 Dissolved with DMF to prepare MoS with a concentration of about 5wt% 2 Buffer layer precursor solution;

[0040] Step S202: Transfer the ITO substrate grown with the PEDOT:PSS hole transport ...

Embodiment 2

[0057] Step S100: preparing a PEDOT:PSS hole transport layer, the specific steps are:

[0058] Step S101: Place the cleaned and dried ITO glass on a homogenizer, uniformly coat the PEDOT:PSS aqueous solution on the ITO glass with a pipette gun and perform spin coating to obtain the precursor film of the PEDOT:PSS hole transport layer, spin coating The rotating speed is 2500 rpm, and the spin coating time is 40 seconds;

[0059] Step S102: placing the ITO substrate of the spin-coated precursor film treated in step S101 on a heating table, and continuously annealing at 120° C. for 20 minutes in an air environment to obtain a PEDOT:PSS hole transport layer with uniform thickness;

[0060] Step S200: Prepare MoS 2 The buffer layer, the specific steps are:

[0061] Step S201: black powder MoS 2 Dissolved with DMF to prepare MoS with a concentration of about 5wt% 2 Buffer layer precursor solution;

[0062] Step S202: Transfer the ITO substrate grown with the PEDOT:PSS hole tran...

Embodiment 3

[0079] Step S100: preparing a PEDOT:PSS hole transport layer, the specific steps are:

[0080] Step S101: Place the cleaned and dried ITO glass on a homogenizer, uniformly coat the PEDOT:PSS aqueous solution on the ITO glass with a pipette gun and perform spin coating to obtain the precursor film of the PEDOT:PSS hole transport layer, spin coating The rotating speed is 2500 rpm, and the spin coating time is 30 seconds;

[0081] Step S102: Place the ITO substrate of the spin-coated precursor film processed in step S101 on a heating table, and continue annealing at 130° C. for 15 minutes in an air environment to obtain a PEDOT:PSS hole transport layer with uniform thickness;

[0082] Step S200: Prepare MoS 2 The buffer layer, the specific steps are:

[0083] Step S201: black powder MoS 2 Dissolved with DMF to prepare MoS with a concentration of about 5wt% 2 Buffer layer precursor solution;

[0084] Step S202: Transfer the ITO substrate grown with the PEDOT:PSS hole transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com