Manufacture technology of health-care sweet potato vermicelli

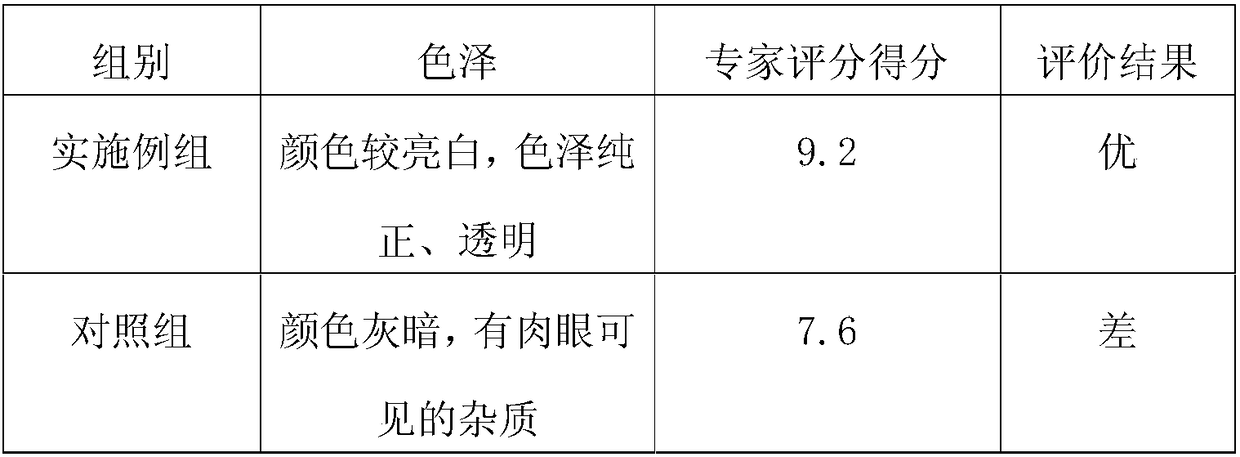

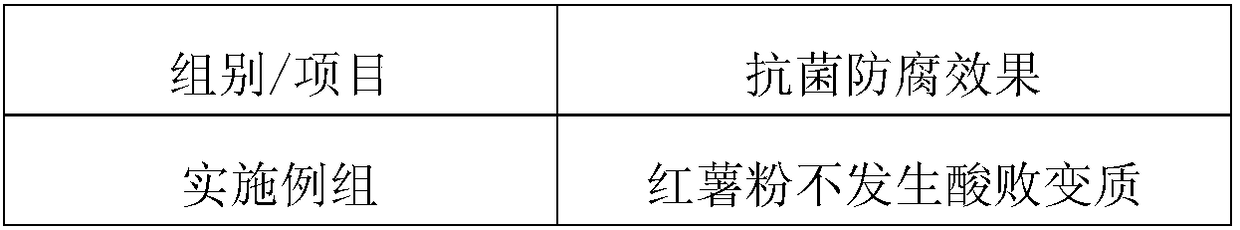

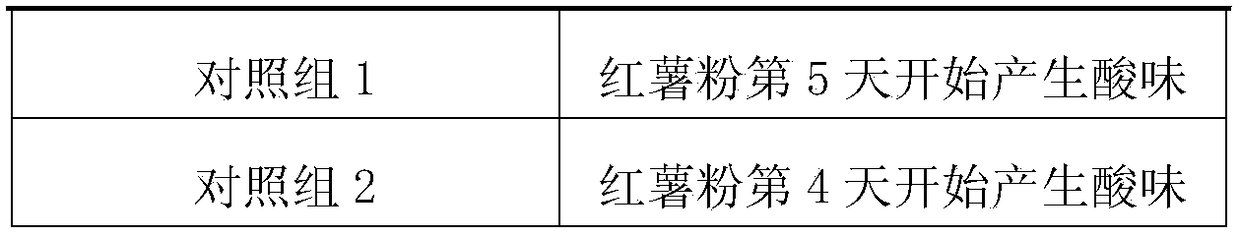

A production process and technology of sweet potato flour, which are applied in the directions of food preservation, function of food ingredients, and food ingredients as antioxidants, etc., can solve the problems of easy oxidative browning of phenolic substances, single health effect of sweet potato flour, and increased energy use. , to enhance the antibacterial and antiseptic effect, inhibit the formation of dark brown substances, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of manufacture craft of health-care sweet potato flour of the present embodiment, comprises the following steps:

[0027] (1) Selection and cleaning of sweet potatoes: select fresh sweet potatoes with smooth skin, no pest spots, and no rot as raw materials, and clean the silt on the surface of the sweet potatoes.

[0028] (2) Beating: put the above-mentioned cleaned sweet potatoes and an equal amount of water into a pulverizer for pulverization to obtain the first slurry, and add 0.5% of the tea leaves by weight of the first slurry to the first slurry to extract Mix and stir the mixture evenly, filter the first slurry with an 80-mesh sieve, collect the slurry for subsequent use, put the filter residue and an equal amount of water into a pulverizer and continue pulverizing to obtain a second slurry, and add it to the second slurry Add 0.1% tea extract by weight of the second slurry, mix and stir evenly, filter the second slurry with an 80-mesh sieve, and mix the f...

Embodiment 2

[0038] A kind of manufacture craft of health-care sweet potato flour of the present embodiment, comprises the following steps:

[0039] (1) Selection and cleaning of sweet potatoes: select fresh sweet potatoes with smooth skin, no pest spots, and no rot as raw materials, and clean the silt on the surface of the sweet potatoes.

[0040] (2) Beating: put the above-mentioned cleaned sweet potatoes and an equal amount of water into a pulverizer for pulverization to obtain the first slurry, and add 1% of the first slurry by weight to the first slurry to extract the tea leaves Mix and stir the material evenly, filter the first slurry with a 100-mesh sieve, collect the slurry for subsequent use, put the filter residue and an equal amount of water into the pulverizer and continue pulverizing to obtain the second slurry, and add it to the second slurry Add 0.3% tea extract by weight of the second slurry, mix and stir evenly, and filter the second slurry with a 100-mesh sieve, and mix the...

Embodiment 3

[0050] A kind of manufacture craft of health-care sweet potato flour of the present embodiment, comprises the following steps:

[0051] (1) Selection and cleaning of sweet potatoes: select fresh sweet potatoes with smooth skin, no pest spots, and no rot as raw materials, and clean the silt on the surface of the sweet potatoes.

[0052] (2) Beating: put the above-mentioned washed sweet potatoes into a pulverizer together with an equal amount of water for pulverization to obtain the first slurry, and add 0.7% of the tea leaves by weight of the first slurry to the first slurry to extract Mix and stir the material evenly, filter the first slurry with a 90-mesh sieve, collect the slurry for subsequent use, put the filter residue and an equal amount of water into a pulverizer and continue pulverizing to obtain a second slurry, and add it to the second slurry Add 0.2% tea extract by weight of the second slurry, mix and stir evenly, filter the second slurry with a 90-mesh sieve, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com