Nanoscale cerium-zirconium solid solution composite oxide, preparation method, catalyst by adoption of nanoscale cerium-zirconium solid solution composite oxide and purpose thereof

A cerium zirconium solid solution, composite oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Excellent performance, catalytic activity, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

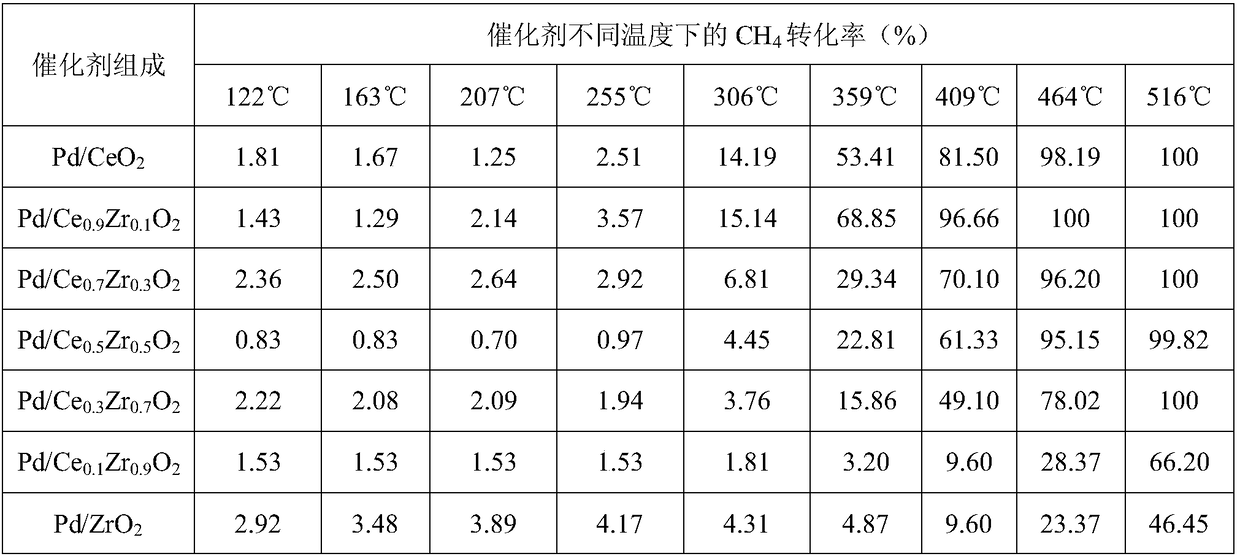

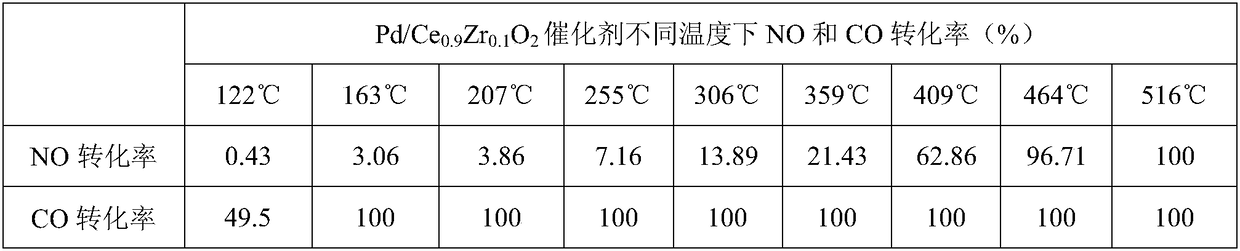

[0045] A nanoscale cerium-zirconium solid solution composite oxide (Ce 0.9 Zr 0.1 o 2 ) and its prepared catalyst (Pd / Ce 0.9 Zr 0.1 o 2 ).

[0046] Preparation:

[0047] 1. Preparation of nano-scale cerium-zirconium solid solution composite oxide

[0048] Using Ce(NO 3 ) 3 ·6H 2 O as Ce source, with Zr(NO 3 ) 4 ·5H 2 O was used as Zr source and NaOH was used as precipitant. More specifically, the following steps are included:

[0049] Firstly, cerium nitrate and zirconium nitrate were prepared into a solution, stirred and dissolved, and an appropriate amount of NaOH solution was added thereto, stirred for 1 hour, and then hydrothermally reacted in an oven at 100°C for 12 hours. Suction filter and wash the reaction product, then place it in a 60°C oven to dry overnight, and finally bake it in an air atmosphere at 550°C for 4h to obtain Ce 0.9 Zr 0.1 o 2 nanomaterials.

[0050] Two, preparation catalyst (Pd / Ce 0.9 Zr 0.1 o 2 )

[0051] A certain amount of P...

Embodiment 2-5

[0053] The difference between Examples 2-5 and Example 1 is that the molar ratios of Ce and Zr in the cerium-zirconium solid solution composite oxide are different, which are respectively 1:9, 3:7, 5:5 and 7:3, and the obtained cerium Zirconium solid solution is the series Ce 0.1 Zr 0.9 o 2 、Ce 0.3 Zr 0.7 o 2 、Ce 0.5 Zr 0.5 o 2 and Ce 0.7 Zr 0.3 o 2 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com