Oxidizing type catalyzing system with good low-temperature NO oxidizing ability and preparation method thereof

A technology of catalytic system and oxidizing ability, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems such as the decline of passive regeneration efficiency of CSF, and achieve the improvement of low-temperature NO oxidation performance, process safety and reliability. Control and coating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] To prepare an oxidation-type catalytic system with good low-temperature NO oxidation ability, comprising the following steps:

[0041] Pre-coating slurry configuration and coating

[0042] 1) Slurry configuration: Add pseudo-boehmite and acetic acid to deionized water in proportion, the weight ratio is 1:1:2, perform ball milling, and then add catalytic materials loaded with precious metals (Pt:Pd=1:1) Alumina-zirconia, beta molecular sieves are added to the binder. The amount of water added is calculated based on the solid content of 42wt%, pH: 4.2, high-energy ball milling for 20min, D 90 = 9.1 μm.

[0043] 2) Determination of solid content: Take 10 g of the slurry in a ceramic dry pot, and place it in a muffle furnace at 500° C. for 5 minutes, and finally detect and calculate the solid content to be 37.9 wt%.

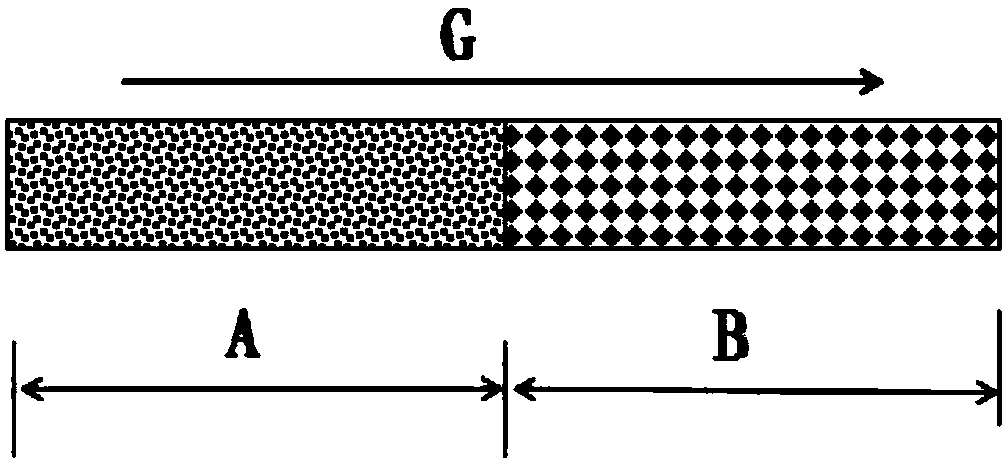

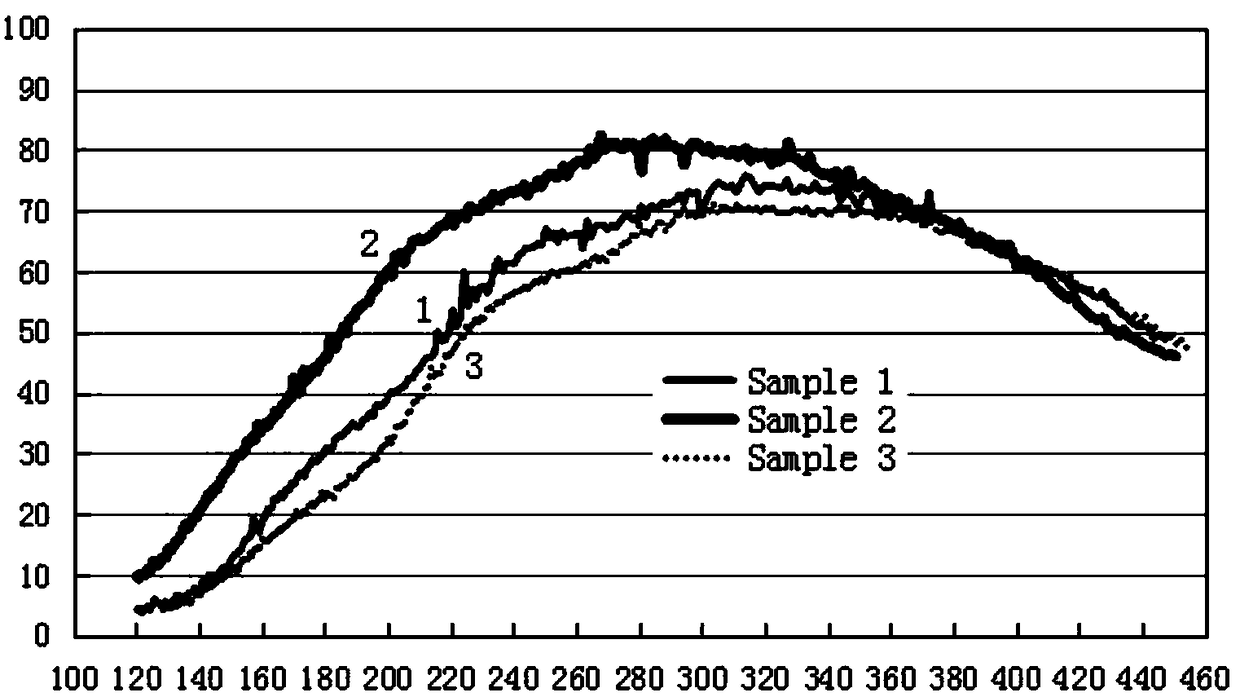

[0044] 3) Coating application: the ratio of the front and back stage areas is 1:1, and the lower grouting coating is carried out according to the loading a...

Embodiment 2

[0054] To prepare an oxidation-type catalytic system with good low-temperature NO oxidation ability, comprising the following steps:

[0055] Pre-coating slurry configuration and coating

[0056] 1) Slurry configuration: Add pseudo-boehmite and acetic acid to deionized water in proportion, with a weight ratio of 1:1:2, perform ball milling, and then add catalytic materials loaded with precious metals (Pt:Pd=5:1) Alumina-silica, cerium-doped beta molecular sieves are added to the binder. The amount of water added is calculated based on the solid content of 39wt%, pH: 3.4, high-energy ball milling for 20min, D 90 =8.4 μm, viscosity: 176 Pa.s.

[0057] 2) Measurement of solid content: Take 10 g of the slurry in a ceramic dry pot, and place it in a muffle furnace at 500° C. for 5 minutes, and finally detect and calculate the solid content to be 39.5 wt%.

[0058] 3) Coating application: the ratio of the front and back stage areas is 1:2, and the lower grouting coating is carrie...

Embodiment 3

[0068] To prepare an oxidation-type catalytic system with good low-temperature NO oxidation ability, comprising the following steps:

[0069] Pre-coating slurry configuration and coating

[0070] 1) Slurry configuration: Add pseudo-boehmite and acetic acid to deionized water in proportion, with a weight ratio of 1:1:2, perform ball milling, and then add catalytic materials loaded with precious metals (Pt:Pd=7:1) Alumina-lanthanum oxide, ZSM-5 molecular sieves are added to the binder. The amount of water added is calculated based on the solid content of 37wt%, pH: 5.2, high-energy ball milling for 20min, D 90 =10 μm, viscosity: 175 Pa.s.

[0071] 2) Measurement of solid content: Take 10 g of the slurry in a ceramic dry pot, and place it in a muffle furnace at 500° C. for 5 minutes of roasting. Finally, the calculated solid content is 36.8 wt%.

[0072] 3) Coating application: the ratio of the front and rear stage areas is 1:4, and the lower grouting coating is carried out ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com