Method for preparing small-sized nano-hydroxyapatite by using carbon dots (CDs) as template

A nano-hydroxyapatite, small-size technology, applied in the direction of nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve the problems that are not suitable for the influence of cancer cells, and achieve the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of carbon dots (CDs):

[0034] Weigh H at a molar ratio of 1:1 2 N(CH 2 ) 10 COOH and NaOH solids were neutralized by adding 25 mL of deionized water, and centrifuged to remove impurities. Then add 25 mL of H 2 N(CH 2 ) 10 A citric acid solution with an equimolar concentration of COOH was stirred vigorously for 30 minutes, and the white precipitate was collected and dried; finally, the dried sample was ground, placed in a muffle furnace at 300°C, thermally oxidized for 2 hours, and cooled naturally; the product after thermal oxidation was extracted by ultrasonic method It was dissolved in deionized water, centrifuged to remove insoluble precipitates, and then the product solution was dialyzed with a dialysis bag with a molecular weight cut-off of 3500D for 48 hours, and then freeze-dried to obtain a purified carbon dot product.

[0035] (2) Preparation of small-sized nano-hydroxyapatite:

[0036] First, measure 10 mL of Ca(NO 3 ) 2 solution, dil...

Embodiment 2

[0038] (1) The preparation of carbon dots (CDs) is the same as in Example 1.

[0039] (2) Preparation of small-sized nano-hydroxyapatite:

[0040] First, measure 10 mL of Ca(NO 3 ) 2 solution, dilute to 23.5mL with deionized water, and then adjust Ca(NO 3 ) 2 The pH of the solution was brought to 10.5. Then slowly add 1.5mL of CDs with a concentration of 24.4g / L to it, keeping the volume of the calcium source solution at 25mL with a concentration of 0.2mol / L; when the CDs-Ca complex precipitate is evenly dispersed, slowly add 30mL of CDs with a concentration of 0.1mol / LNa 3 PO 4 solution; then the mixed solution was transferred into a polytetrafluoroethylene autoclave, reacted at 180°C under hydrothermal conditions for 8h, cooled naturally to room temperature, washed with deionized water and ethanol for 3 times, dried in an oven at 50°C, and ground to obtain Small size nano-hydroxyapatite S3.

Embodiment 3

[0042] (1) The preparation of carbon dots (CDs) is the same as in Example 1.

[0043] (2) Preparation of small-sized nano-hydroxyapatite:

[0044] First, measure 10 mL of Ca(NO 3 ) 2solution, dilute it to 22.5mL with deionized water, and then adjust the Ca(NO 3 ) 2 The pH of the solution was brought to 10.5. Then slowly add 2.5mL of CDs with a concentration of 24.4g / L to it, keeping the volume of the calcium source solution at 25mL with a concentration of 0.2mol / L; until the CDs-Ca complex precipitate is evenly dispersed, slowly add 30mL of CDs with a concentration of 0.1mol / LNa 3 PO 4 solution; then the mixed solution was transferred into a polytetrafluoroethylene autoclave, reacted at 180°C under hydrothermal conditions for 8h, cooled naturally to room temperature, washed with deionized water and ethanol for 3 times, dried in an oven at 50°C, and ground to obtain Small size nano-hydroxyapatite S4.

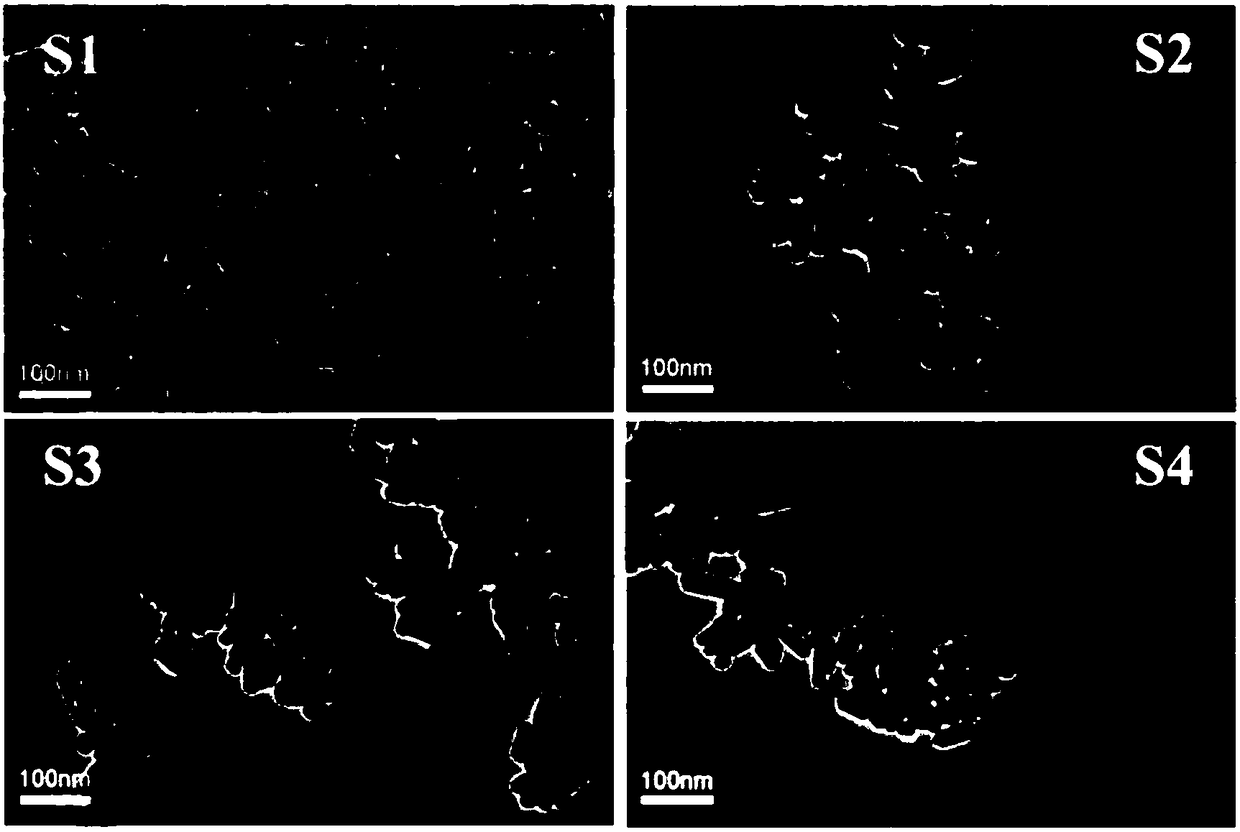

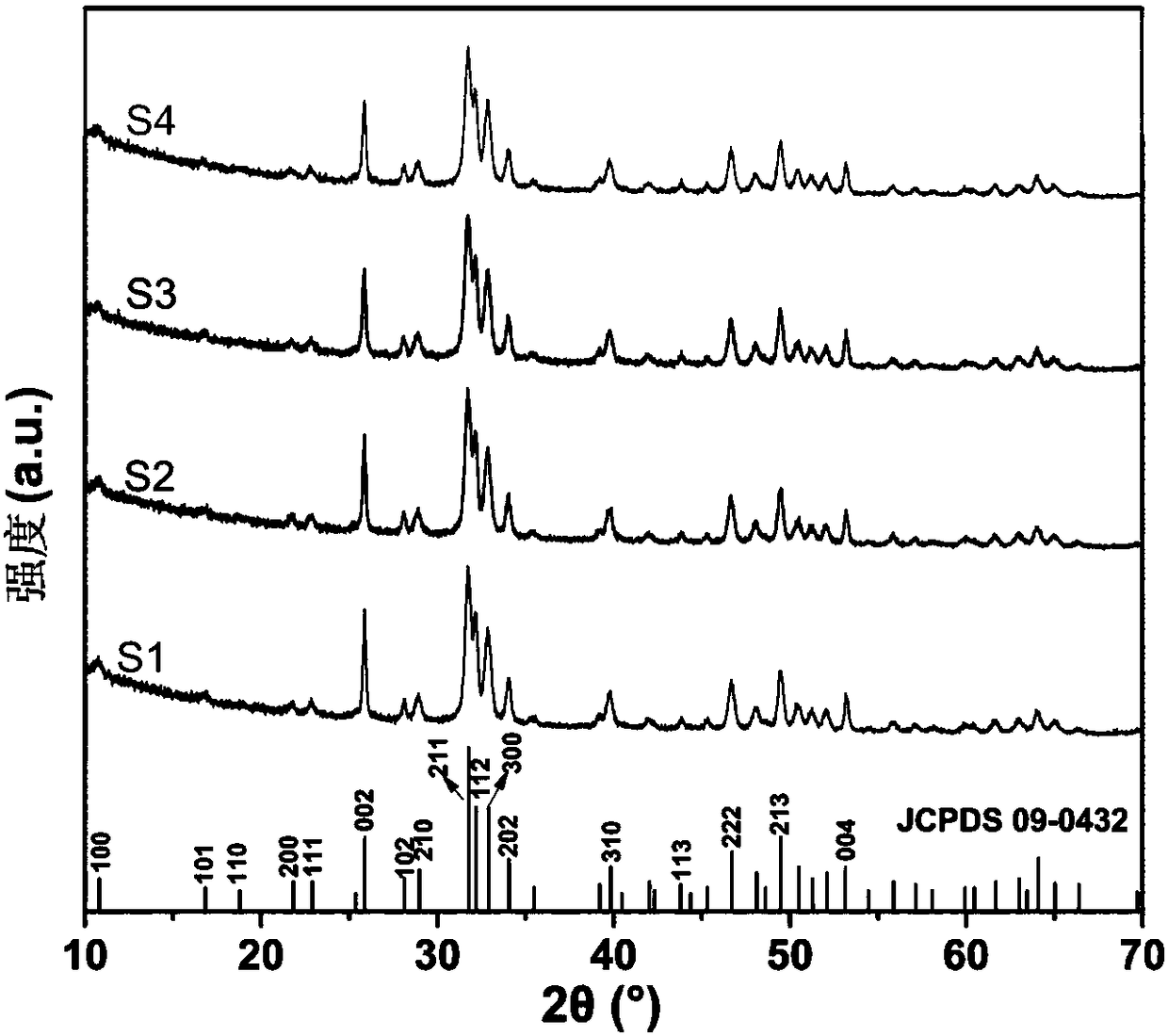

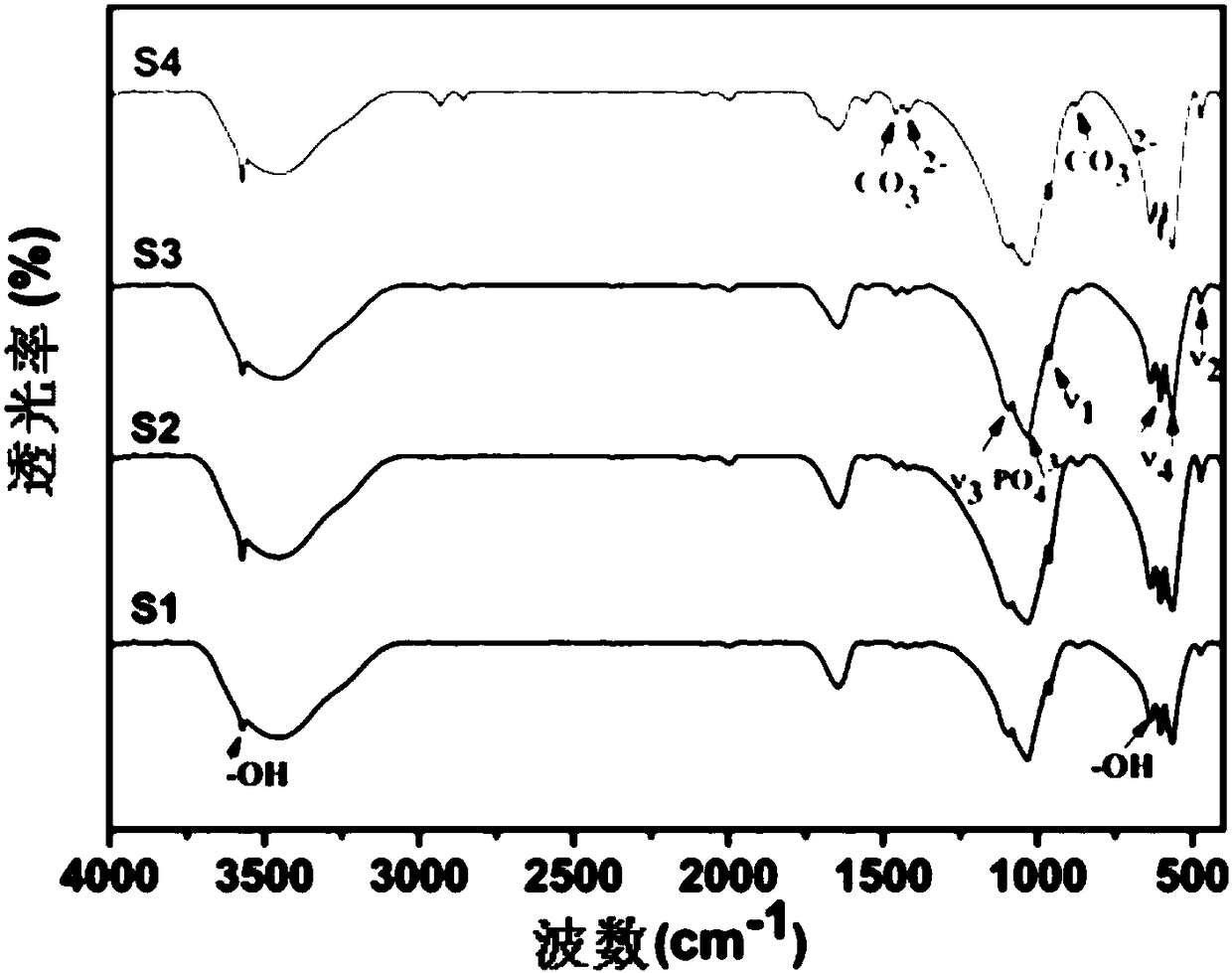

[0045] The transmission electron microscope figure (TEM) of the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com