Preparation method of delaminated two-dimensional transition metal carbide or carbonitride-trititanium dicarbide with improved antibacterial property

An antibacterial and solution technology, applied in the field of preparation of MXene-Ti3C2, can solve the problems of unsatisfactory layering effect, low antibacterial properties, and restricting the development of antibacterial materials, and achieve good layering effect, improve antibacterial properties, and antibacterial properties. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) 5g Ti 3 AlC 2 -MAX phase ceramic powder was slowly added to 100mL of HF solution with a mass concentration of 49% to obtain an intermediate solution;

[0054] (2) reacting the intermediate solution obtained in step (1) in a magnetic stirrer at 50° C. in an oil bath for 36 hours;

[0055] (3) After the reaction, the obtained solution was evenly divided into 6 parts and poured into 6 centrifuge bottles of 350mL, and distilled water was added to 2 / 3 of the place, shaken and centrifuged at 3500rpm for 5min, and the supernatant was tested. Pour out the supernatant after the pH value, and wash the precipitate with deionized water, shake it well and then centrifuge under the same conditions, repeat 6 times; measure the pH of the final supernatant = 5.6, and then wash the precipitate with absolute ethanol , centrifuge after shaking, keep the same rotation speed and centrifugation time and repeat twice;

[0056] (4) Completely disperse and suspend the obtained precipitate...

Embodiment 2

[0066] MXene-Ti 3 C 2 The powder preparation method is the same as in Example 1.

[0067] (1) 1g MXene-Ti 3 C 2 The powder is uniformly dispersed in 100ml of isopropylamine (IPA) aqueous solution with a volume concentration of 25%, and stirred and reacted for 18h at 25°C in a magnetic stirrer;

[0068] (2) After the reaction, centrifuge the obtained solution at a speed of 3500rpm for 15min, discard the supernatant, wash the precipitate with deionized water, oscillate and shake well, and then centrifuge under the same conditions, repeating 2 times;

[0069](3) uniformly disperse the obtained precipitate in 500ml deionized water, and perform ultrasonic treatment (100% power and 45k Hz frequency) under argon gas for 6h;

[0070] (4) Pour the ultrasonically treated solution evenly into a watch glass, and dry it in a vacuum oven for 24 hours at room temperature to obtain a layered MXene-Ti with improved antibacterial properties. 3 C 2 Material

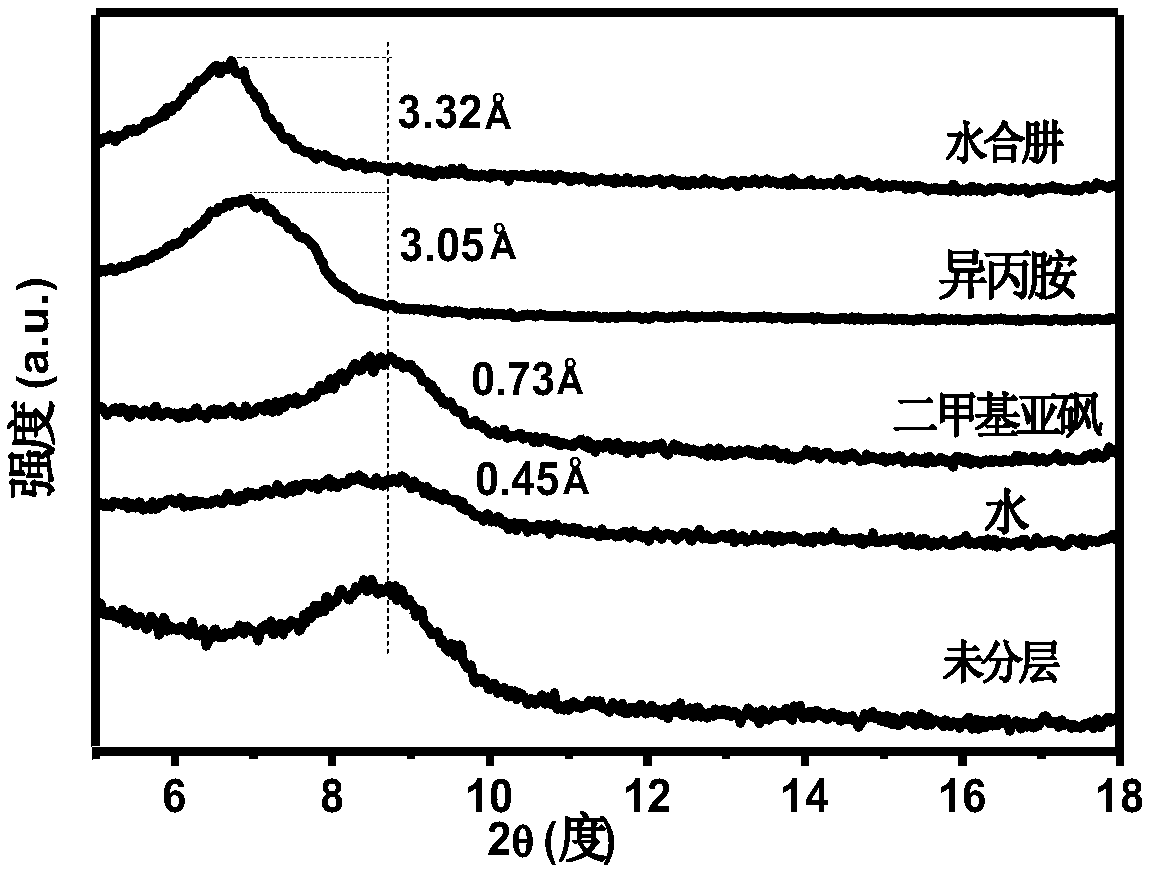

[0071] The prepared layered M...

Embodiment 3

[0076] Hierarchical MXene-Ti provided as embodiment 1 3 C 2 , the difference is that 80 mL of HF solution with a mass concentration of 49% is added in the step (1), the temperature of the stirring reaction in the step (1) is 40° C., and the time of the stirring reaction is 36 h, and the step (2) The rotating speed of the washing centrifuge is 2500rpm, the temperature of the stirring reaction in the step (3) is 20°C, the time of the stirring reaction is 18h, the frequency of the ultrasonic treatment in the step (4) is 40kHz, and the power of the ultrasonic treatment is 100 %, MXene-Ti will be used in step (5) 3 C 2 The powder is evenly dispersed in 80ml of hydrazine hydrate.

[0077] The prepared layered MXene-Ti 3 C 2 The layer spacing and lattice constant of the material are shown in Table 2; the layered MXene-Ti 3 C 2 The antibacterial activity of MXene-Ti was significantly higher than that of unlayered MXene-Ti 3 C 2 , and showed time and concentration dependence, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com