Preparation method and application of copper-zinc-tin-sulfur nano-powder with ultrasound catalysis activity

A copper-zinc-tin-sulfur, nano-powder technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of long catalysis time, low catalytic degradation efficiency, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.467g cupric chloride, 0.183g anhydrous zinc chloride, 0.467g tin chloride pentahydrate, 0.567g thiourea, 82.35g deionized water and stir until completely dissolved, add 2.050g PEG400, cupric chloride, chlorine The mass ratio of zinc chloride, tin chloride, thiourea, PEG400, and water is 2.55:1:2.55:3.10:11.20:450, magnetically stirred for 60 minutes, and the speed is 600 rpm.

[0032] Pour the above mixed solution into a 100ml hydrothermal reaction kettle, heat in a muffle furnace at 210°C for 30 hours and then cool to room temperature. After centrifuging for 10 minutes, remove the precipitate from the lower layer and rinse it with deionized water. Repeat the operation 6 times. Dry at 105°C for 30 hours.

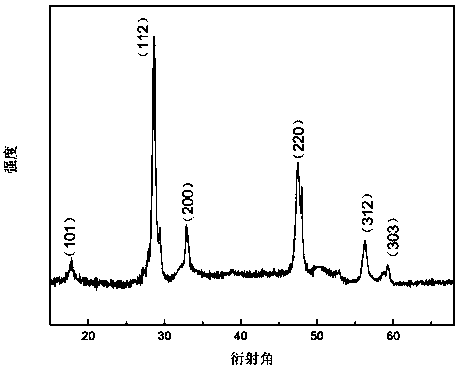

[0033] TEM of the product as figure 1 Shown; The ultra-high resolution transmission electron microscope picture of the product is shown in figure 2 Shown; The X-ray diffraction spectrum of product is as image 3 shown.

[0034] This embodiment is tested f...

Embodiment 2

[0039] Weigh 0.467g cupric chloride, 0.183g anhydrous zinc chloride, 0.467g tin chloride pentahydrate, 0.567g thiourea, 82.35g deionized water, mix and stir until completely dissolved, add 1.922g PEG400, cupric chloride, chlorine The mass ratio of zinc chloride, tin chloride, thiourea, PEG400, and water is 2.55:1:2.55:3.10:10.50:450, magnetically stirred for 60 minutes, and the speed is 600 rpm.

[0040] Pour the above mixed solution into a 100ml hydrothermal reaction kettle, heat in a muffle furnace at 200°C for 24 hours and then cool to room temperature. After centrifuging for 10 minutes, remove the precipitate from the lower layer and rinse it with deionized water. Repeat the operation 6 times. Dry at 105°C for 28 hours.

[0041] This embodiment is tested for the ultrasonic catalytic performance of the prepared copper zinc tin sulfur under the condition of no light ultrasonic irradiation:

[0042] Get 20mg of the prepared copper-zinc-tin-sulfur nano-powder with ultrasonic ...

Embodiment 3

[0046] Weigh 0.467g cupric chloride, 0.183g anhydrous zinc chloride, 0.467g tin chloride pentahydrate, 0.567g thiourea, 82.35g deionized water and stir until completely dissolved, add 1.976g PEG400, cupric chloride, chlorine The mass ratio of zinc chloride, tin chloride, thiourea, PEG400, and water is 2.55:1:2.55:3.10:10.80:450, magnetically stirred for 120 minutes, and the rotation speed is 800 rpm.

[0047] Pour the above mixed solution into a 100ml hydrothermal reaction kettle, heat in a muffle furnace at 200°C for 24 hours, then cool to room temperature, centrifuge for 15 minutes, remove the lower layer of precipitate and rinse it with deionized water, repeat the operation 8 times, and put the precipitate in Dry at 100°C for 30 hours. This embodiment is tested for the ultrasonic catalytic performance of the prepared copper zinc tin sulfur under the condition of no light ultrasonic irradiation:

[0048] Get 20mg of the prepared copper-zinc-tin-sulfur nano-powder with ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com