Lead peroxide electrode as well as preparation method and application thereof

A lead peroxide and lead oxide technology, applied in the field of electrochemical materials, can solve the problems of short service life of lead peroxide electrodes, and achieve the effects of easy mass production, good stability and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

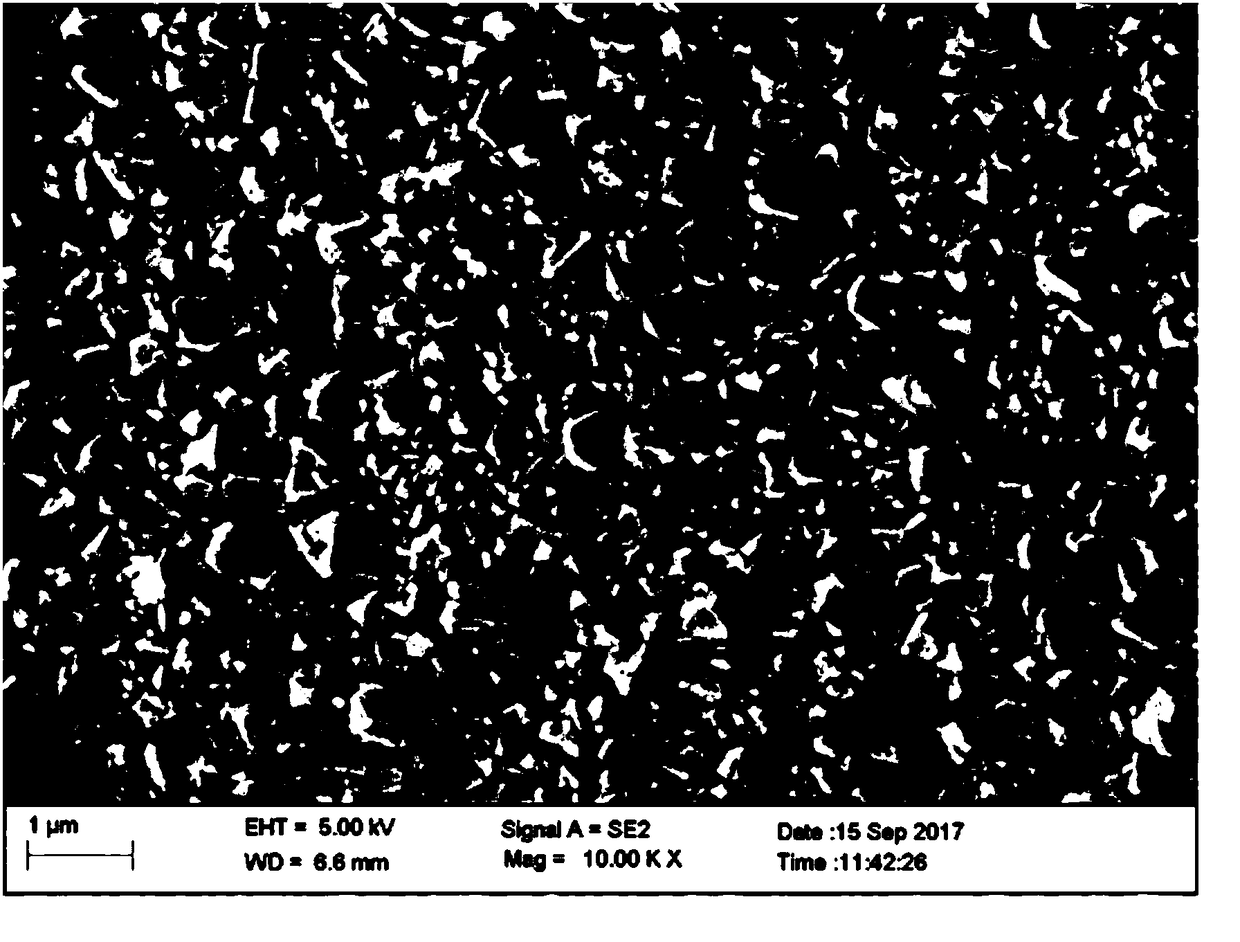

[0083] Melt the commercially available lead sheet in a muffle furnace, extract the lead single substance, pour it into a mold, pressurize it at 30MPa to make it about 0.5mm thick, and then cut it into 1×1cm square lead sheet; put it in the air for 24 hours to make its surface Slowly oxidize, then place in a muffle furnace and heat to 300°C, take out the lead sheet after 3 hours. After natural cooling, place it in 0.1mol / L sodium sulfate solution with electrode holders as the anode, and use a large-area stainless steel sheet as the cathode, and use 5mA / cm 2 Current density and constant current electrolysis for 180 minutes, the surface can obtain a lead peroxide electrode with an anodized lead peroxide layer.

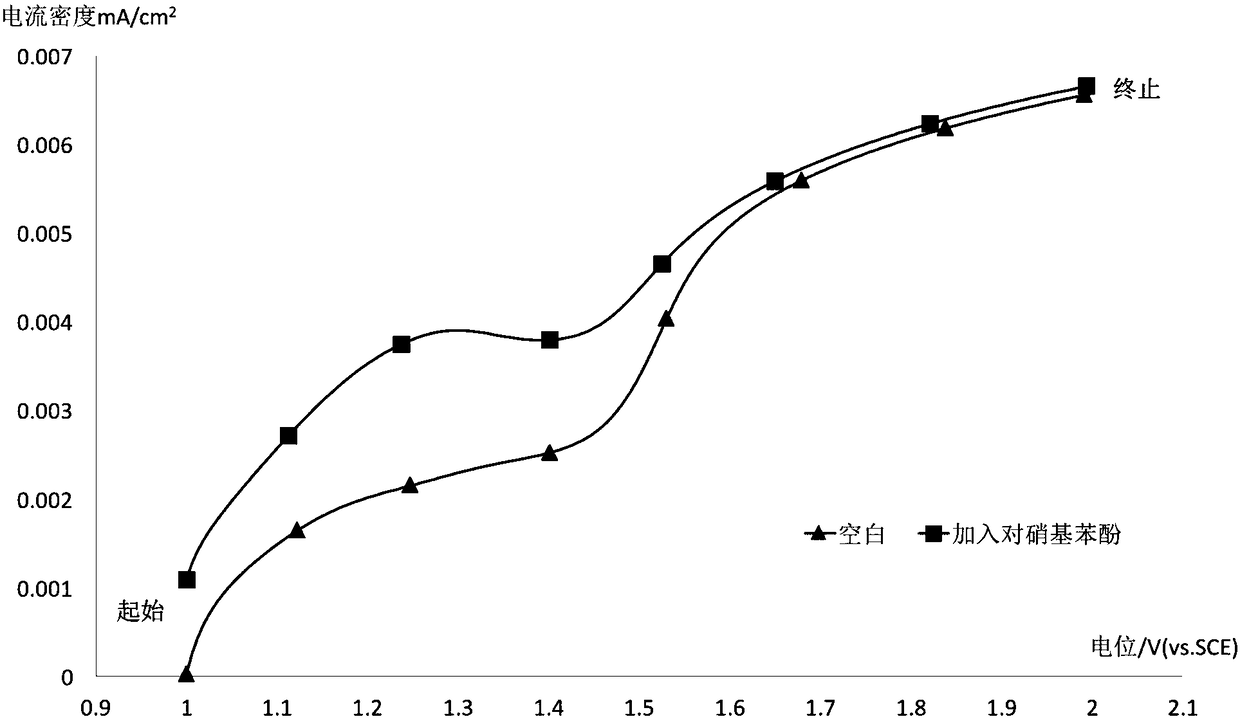

[0084] Use this electrode as an anode, an equal-area platinum electrode as a cathode, a calomel electrode as a reference electrode, and 100ml of 0.1mol / L sodium sulfate as a blank solution, and electrolyze p-nitrophenol in a three-chamber electrolytic cell with an initial...

Embodiment 2

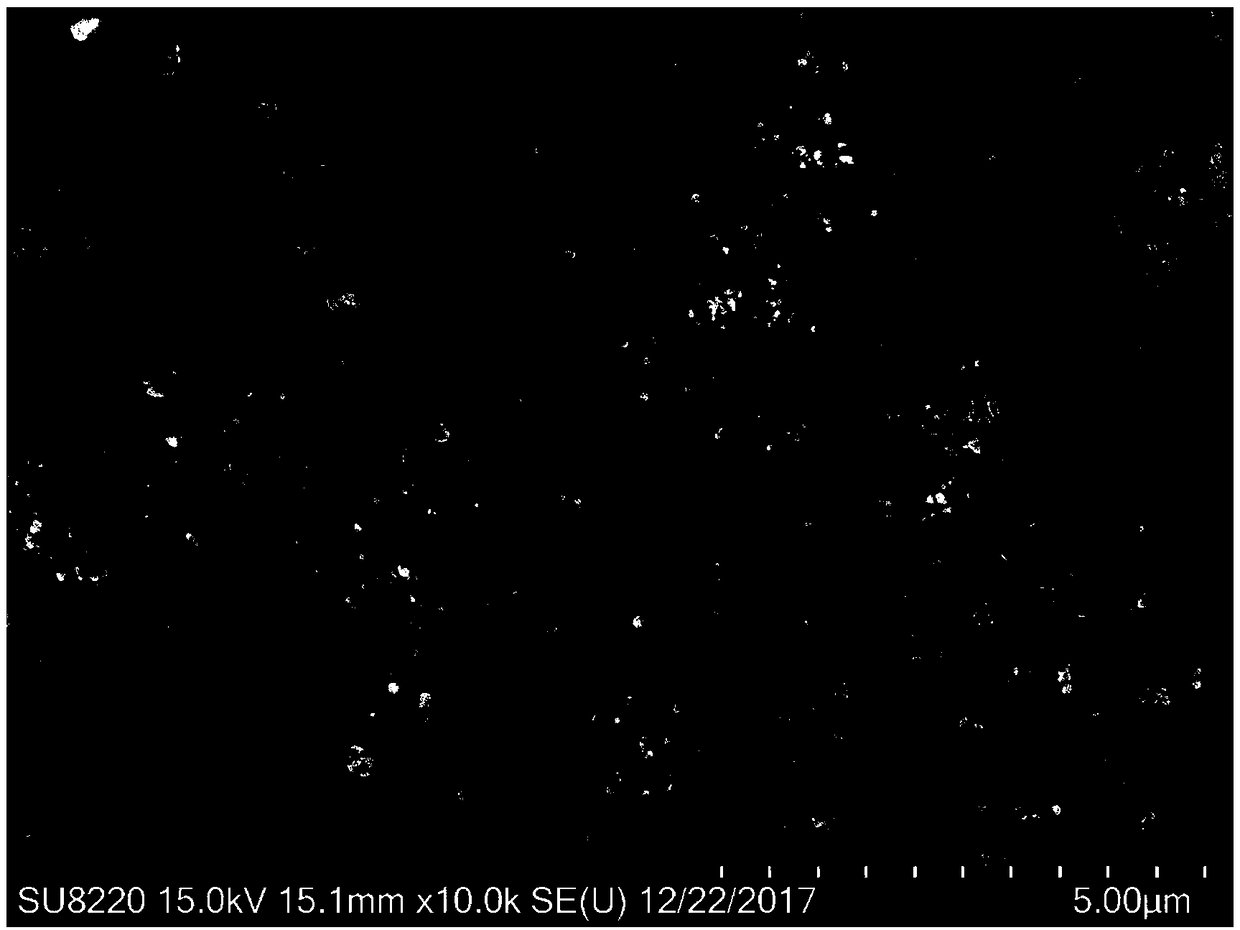

[0089] Melt the commercially available lead plate in a muffle furnace, extract the lead single substance, pour it into a mold, pressurize it at 20MPa to make it about 0.5mm thick, and then cut it into 1×1cm square lead sheet; put it in the air for 12 hours to make its surface Slowly oxidize, then place in a muffle furnace and heat to 310°C, take out the lead piece after 6 hours. After natural cooling, place it in 0.2mol / L potassium sulfate solution with electrode clamps as the anode, and an equal-area stainless steel sheet as the cathode, and use a 2.2V cell piezoelectric electrolysis for 180min to obtain the peroxidation of the anodized lead peroxide layer. lead electrode.

[0090] Use the electrode to electrolyze 150mL, 20mg / L p-nitrophenol solution at a constant current, current 5mA, after 10h electrolysis, test with potassium dichromate titration method, the chemical oxygen demand (Chemical Oxygen Demand, COD) of p-nitrophenol solution From 54.6mg / L to 20.0mg / L.

[0091]...

Embodiment 3

[0095] Melt the commercially available lead sheet in a muffle furnace, extract the lead single substance, pour it into shape, pressurize it at 10MPa to make it about 0.5mm thick, and then cut it into 1×1cm square lead sheet; put it in the air for 18 hours to make its surface Slowly oxidize, then place in a muffle furnace and heat to 320°C, take out the lead piece after 12 hours. After natural cooling, place it in a 0.5mol / L sodium chloride solution with an electrode holder as the anode, and an equal-area platinum sheet as the cathode, at 20mA / cm 2 Current density and constant current electrolysis for 60 minutes to obtain a lead peroxide electrode with an anodized lead peroxide layer.

[0096] Use the electrode constant current to electrolyze the effluent sample of the secondary sedimentation tank in the wastewater treatment system of the farm. The current is 10mA. After electrolysis for 10 hours, the COD of the wastewater is reduced from 146.7mg / L to 73.3mg / L by the potassium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com