High-selectivity ultrasensitive peroxided nitrite ratio fluorescence probe

A compound, branched chain alkoxy technology, applied in the field of highly selective ultrasensitive peroxynitrite ratio fluorescent probes, can solve the problems of complex synthesis, poor water solubility, poor selectivity, etc., and achieve simple synthesis, sensitive response, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]

[0034] Dissolve 200mg (0.38mmol) of benzothiazole-rhodamine compounds in 15mL of absolute ethanol, then add 57mg (1.14mmol) of hydrazine hydrate, reflux for 6h, and spin evaporate the solvent under reduced pressure. If a purer product is to be obtained, the crude product can be separated by column chromatography with a mixed system of dichloromethane and methanol (for example, v / v, 100:1) to obtain a pure product, and 110 mg of a light yellow pure product is obtained, and the productive rate is 54 %.

[0035] 1 H NMR verified the correctness of the product structure.

Embodiment 2

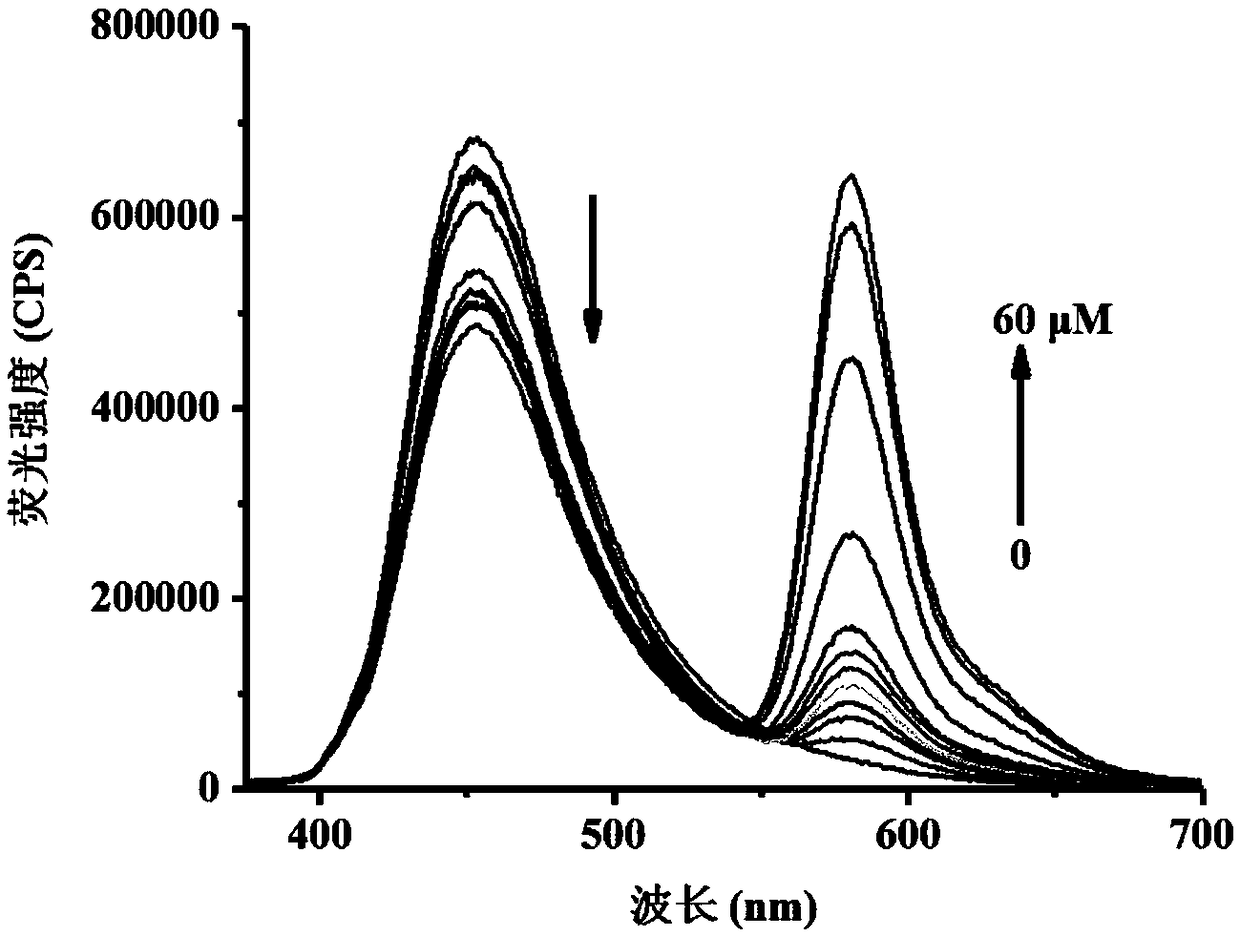

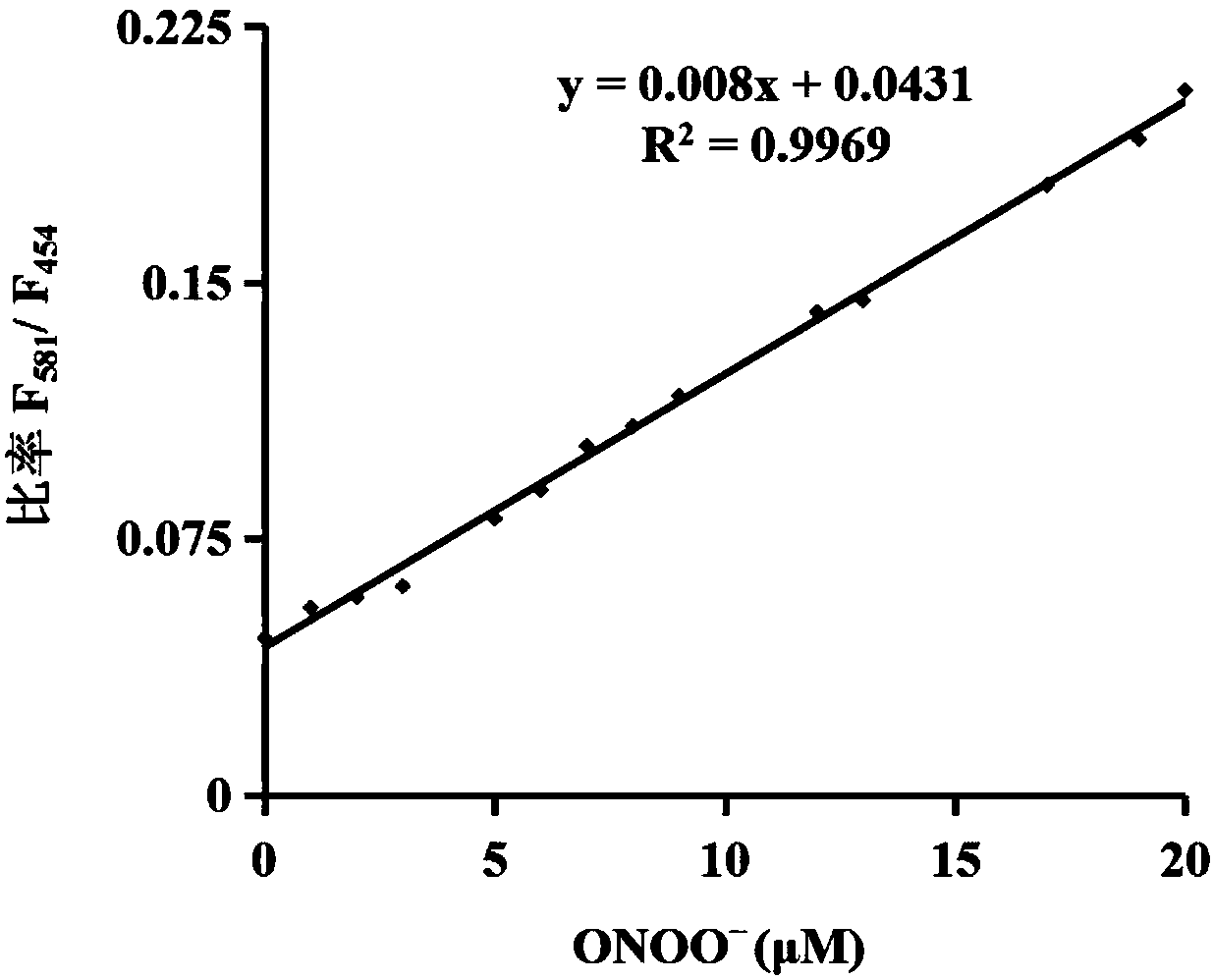

[0037] Figure 1a is the fluorescence spectrum of the probe (5 μM) before and after adding peroxynitrite (0-60 μM). Figure 1b It is a linear relationship graph of different concentrations of peroxynitrite (0-20 μM) to probe (5 μM).

[0038] Configure multiple parallel samples with a probe concentration of 5 μM in a 10mL colorimetric tube, then add different concentrations of peroxynitrite into the test system, shake it evenly and let it stand. The above-mentioned determination is carried out in DMSO: water=3: 7 (20mMPBS, pH7.4) system, the probe used is the probe prepared in Example 1, and all spectral tests are all in Measured at 25°C.

[0039] Fluorescence intensity changes were measured with a fluorescence spectrometer, from Figure 1a It can be clearly seen that as the concentration of peroxynitrite increases, the fluorescence intensity at 454 nm decreases, and the fluorescence intensity at 581 nm increases gradually. and, by Figure 1b It can be seen that after the fl...

Embodiment 3

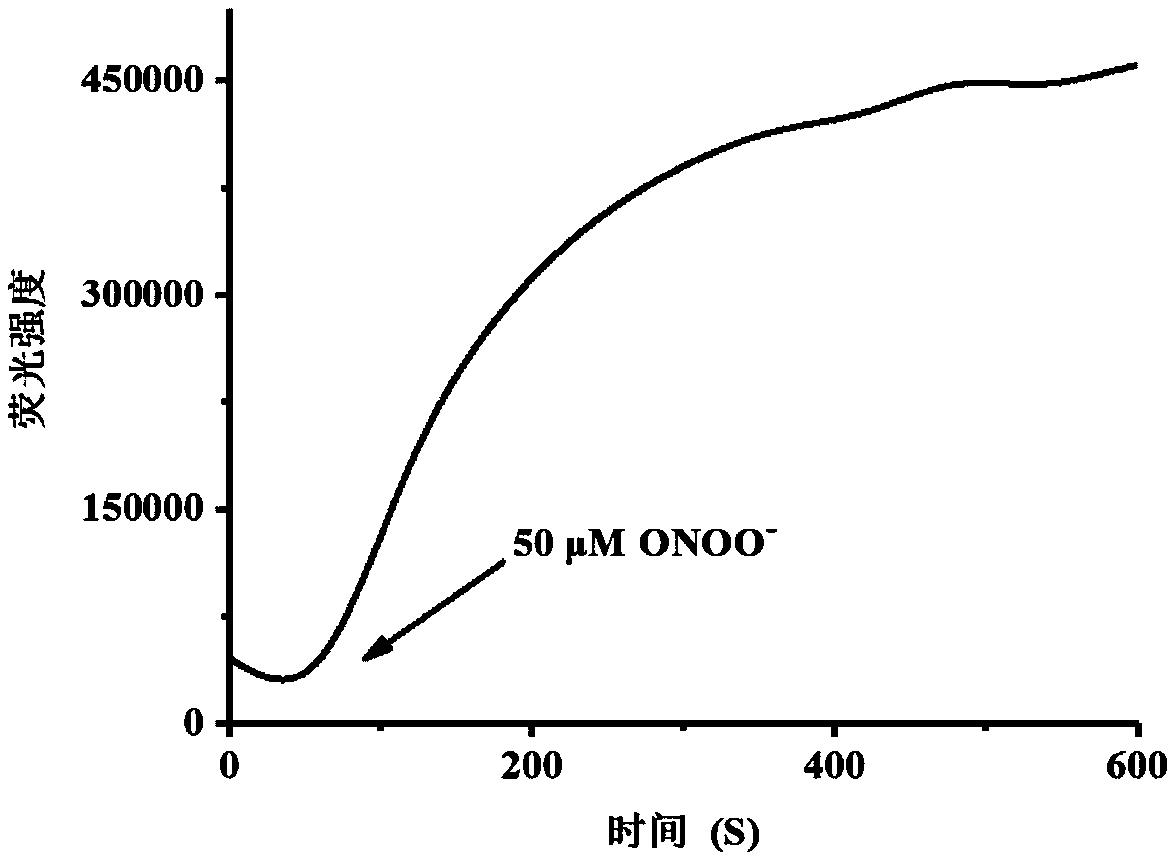

[0041] figure 2 is the response time of the probe (5 μM) after addition of peroxynitrite (50 μM). Take 50 μL from the probe mother solution and place it in 10 mL of the test system, then add 50 μM peroxynitrite into the test system, shake it evenly, and measure the change of its fluorescence intensity with a fluorescence spectrometer immediately. The above-mentioned determination is carried out in DMSO: water=3: 7 (20mM PBS, pH7.4) system, the probe used is the probe prepared in Example 1, and all spectral tests are Measured at 25°C.

[0042] It can be clearly seen from the figure that after the addition of peroxynitrite, the fluorescence intensity reaches the maximum value and remains unchanged after detection for about 6 minutes, which indicates that the probe reacts rapidly with peroxynitrite and can be used for peroxynitrite. The determination of nitrate provides a rapid analytical method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com