Electrochemical method for separating arsenic and alkali from arsenic-alkali residue

An arsenic-alkali residue and electrochemical technology, applied in the field of comprehensive utilization of resources, can solve the problems of low efficiency, high energy consumption, incomplete arsenic-alkali separation, etc., and achieve the effects of low energy consumption, reduced recovery difficulty, and complete arsenic-alkali separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

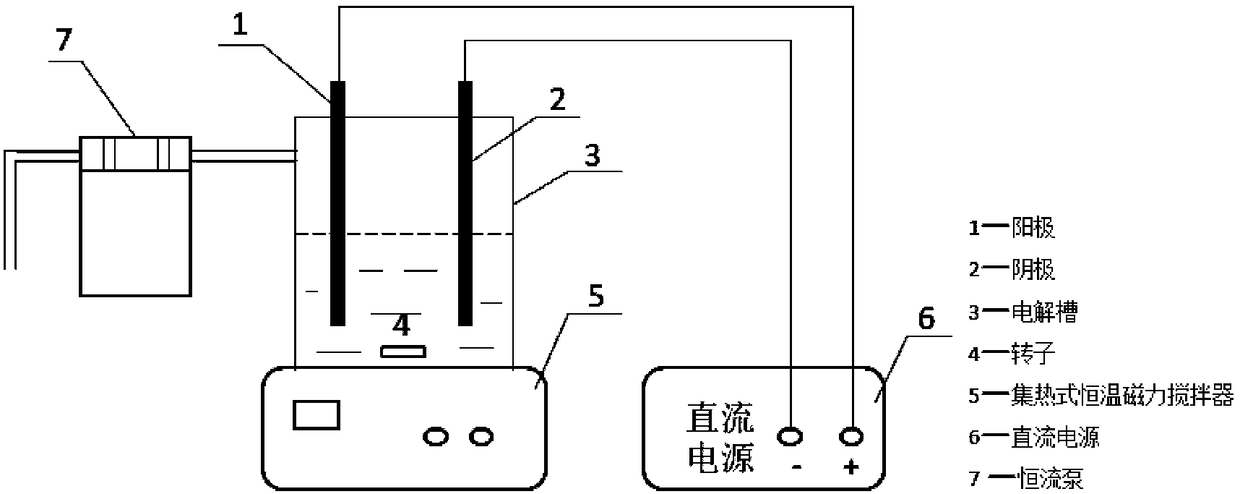

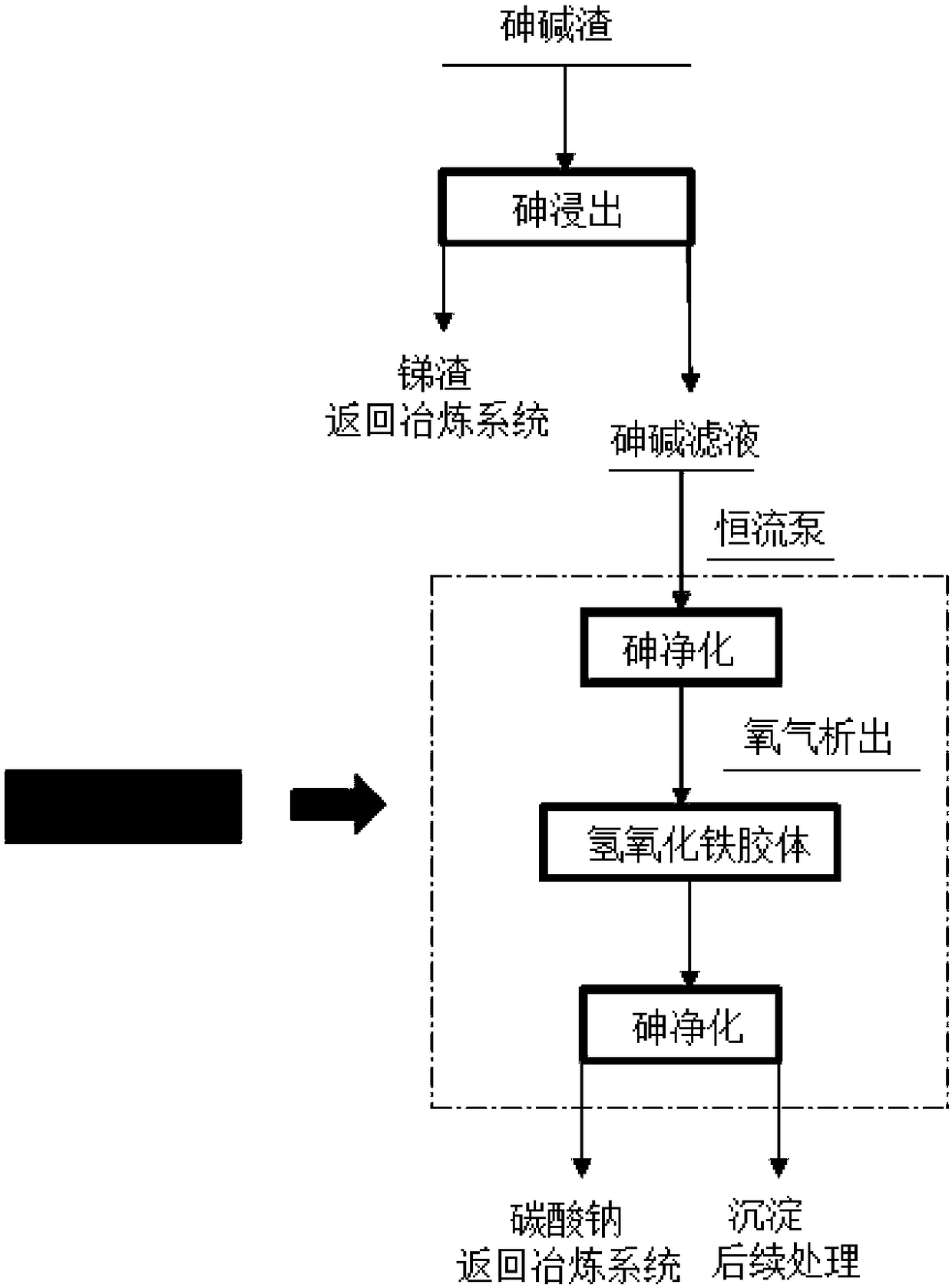

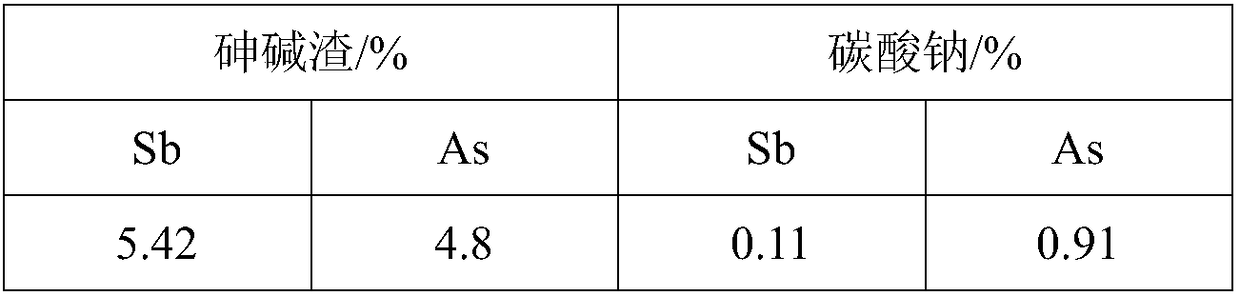

[0035] Using this process to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, the As content is as high as 4.8%, the Sb content is 5.42%, and the sodium carbonate content is 25.31%. Take 50g of arsenic-alkali slag, add 5g of sodium peroxide, grind for 10min, and ensure that -200 mesh accounts for 82%, add 250mL of water, stir at 100r / min at a high speed, leaching temperature at 80°C, leaching time of 60min, and the filtrate obtained by filtering is carbonic acid-containing The mixed solution of sodium and sodium arsenate, the leaching residue is returned to the antimony smelting system. Next, add a sodium carbonate solution with a concentration of 1% to the electrolytic cell, use the iron electrode as the anode, and use the carbon electrode as the cathode to perform electrolysis at a temperature of 50°C and a current density of 25mA / cm 2 , the time is 35min, active Fe is generated in the anode area 2+ Ions are added to the arsenic-alkali slag leaching ...

Embodiment 2

[0039] Using this process to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, the As content of the polluted acid is as high as 10.28%, the Sb content is 4.12%, and the sodium carbonate content is 26.61%. Take 50g of arsenic-alkali slag, add 12g of sodium peroxide, grind for 10 minutes to ensure that -200 mesh accounts for 86%, add 250mL of water, stir at 80r / min at a high speed, leaching temperature is 85°C, leaching time is 60min, and the filtrate obtained by filtering is carbonic acid-containing The mixed solution of sodium and sodium arsenate, and the leached slag are returned to the antimony smelting system. Next, add a concentration of 1% sodium carbonate solution to the electrolytic cell, use the iron electrode as the anode, and use the carbon electrode as the cathode to perform electrolysis at a temperature of 60°C and a current density of 30mA / cm 2 , the time is 30min, active Fe is generated in the anode area 2+ Ions are added to the arsenic-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com