Catalytic converter capable of effectively removing exhaust pollution at vehicle starting stage

A technology for vehicle startup and catalytic purifier, which is applied to the electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, exhaust gas treatment, etc. problem, to achieve the effect of eliminating a large amount of pollution, simple structure and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

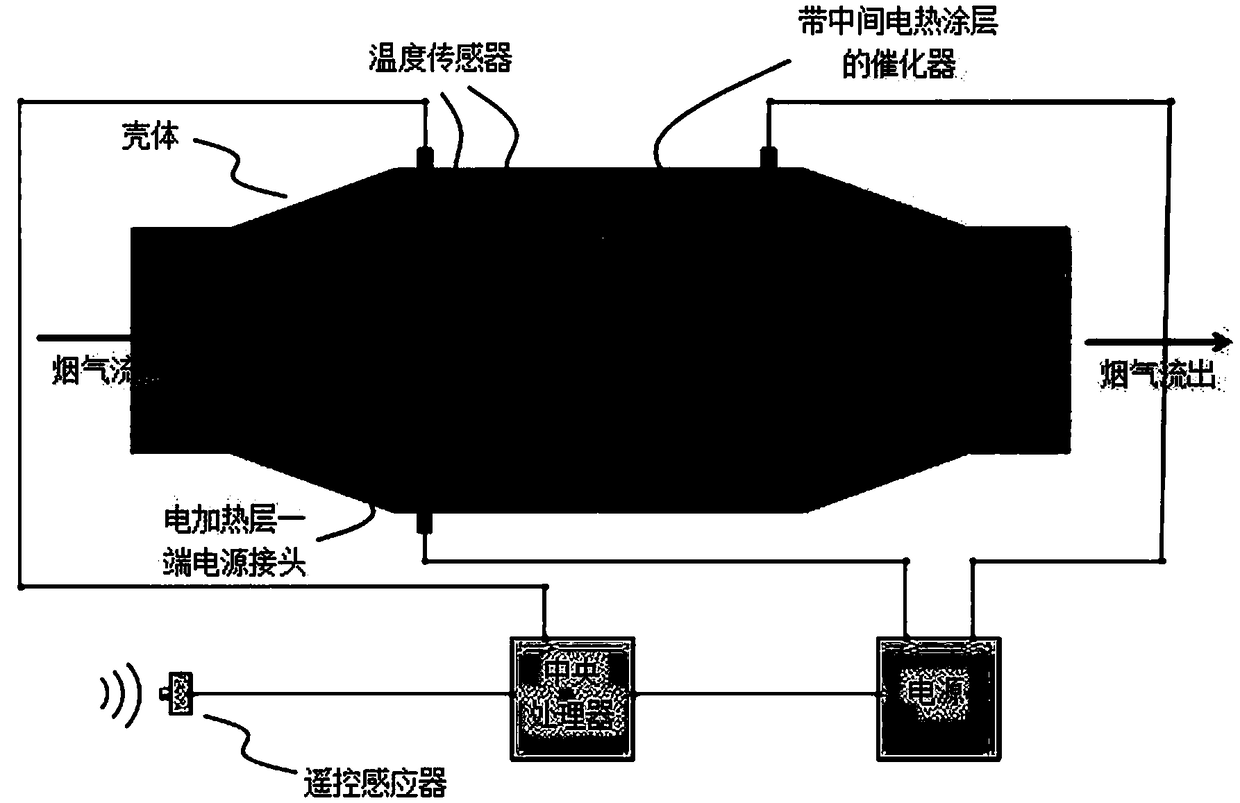

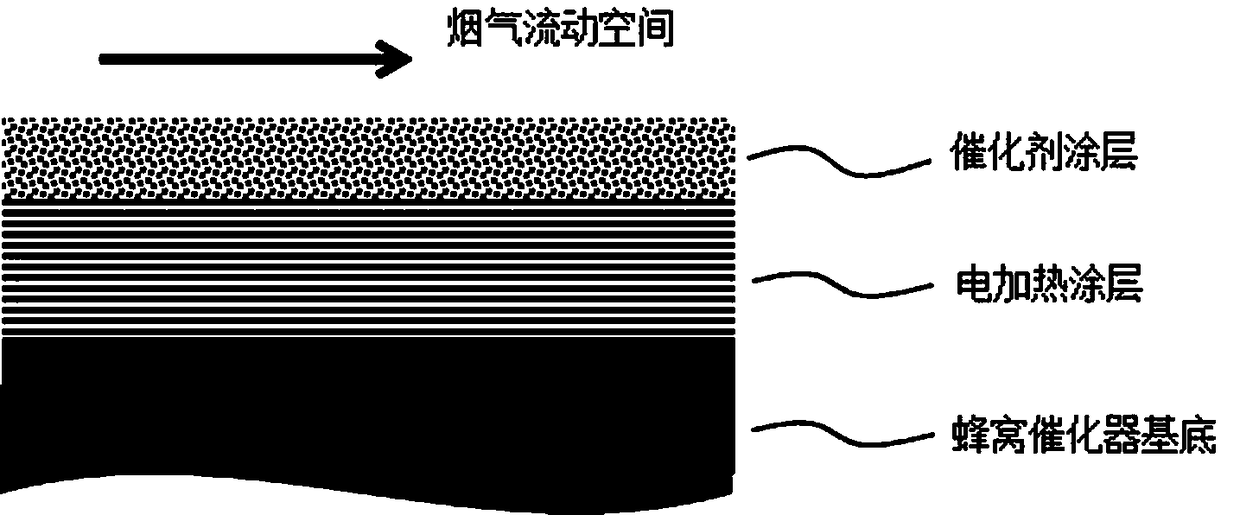

[0012] Such as figure 1 As shown, a catalytic converter that effectively removes exhaust pollution during vehicle start-up includes a central processing unit, a flue gas honeycomb catalytic converter with an electric heating layer, an on-board power supply for heating the electrothermal coating, and a temperature sensor for measuring the temperature of the catalyst layer ( To prevent failure of one sensor, set two or more at different positions), sensors for receiving remote control signals, etc. When the driver of the vehicle enters the sensing range of the aforementioned sensor with a matching remote control device (power-on state), the sensor can start the power supply through the central processing unit, so that the electric heating layer starts to heat the catalyst layer. When the temperature of the catalyst layer rises to sufficient catalytic activity (the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com