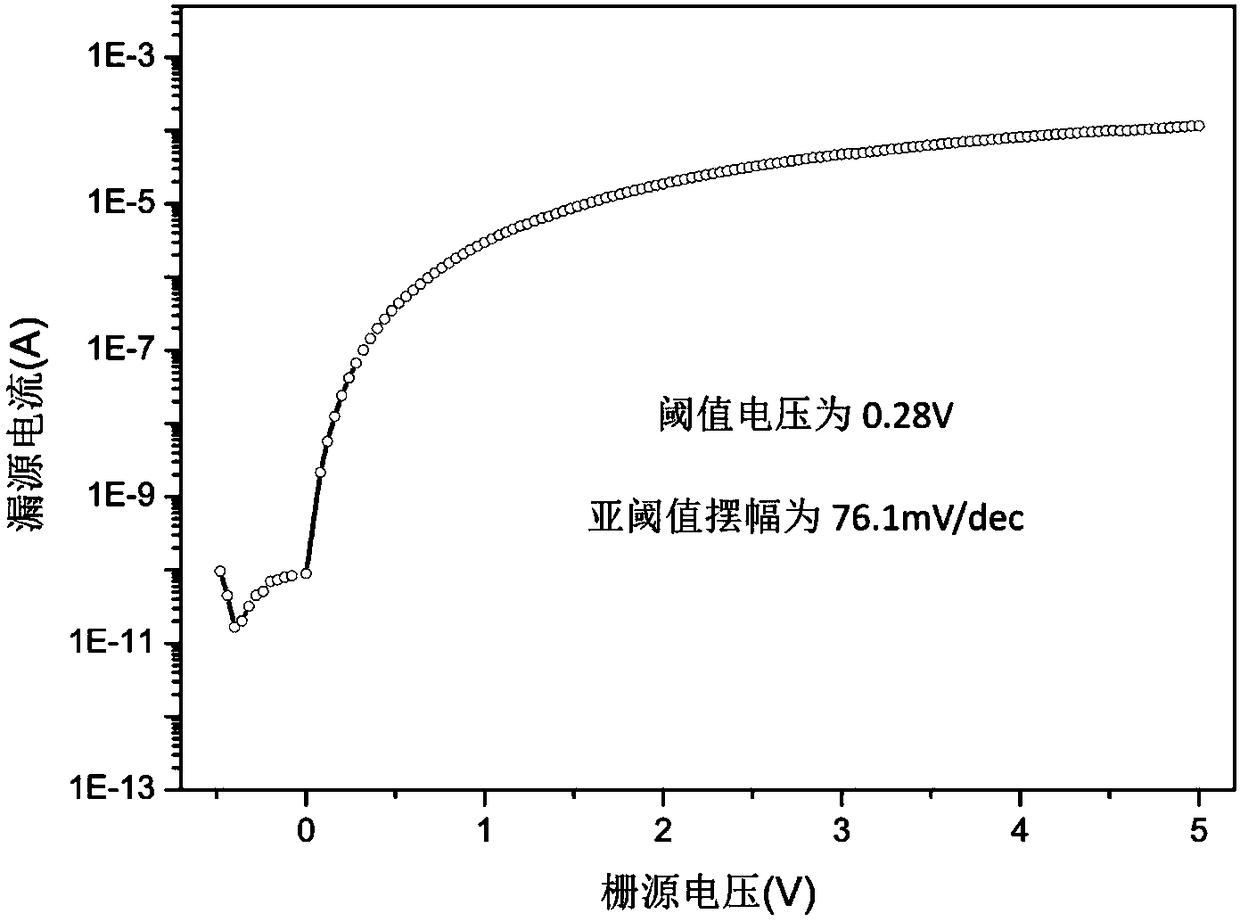

Preparation method of indium oxide thin film transistor of low sub-threshold value amplitude of oscillation

A sub-threshold swing, thin-film transistor technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems that are not conducive to the development of metal oxide thin-film transistors, use toxic solvents, and have many process steps. The effect of large-scale production and application, simple preparation operation and strong process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

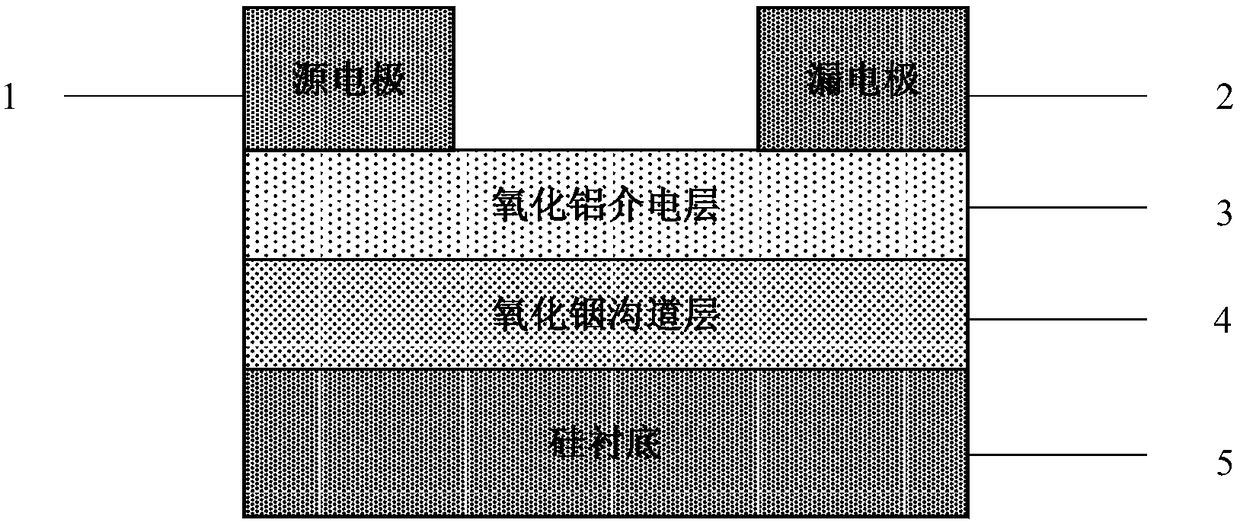

[0028] Indium nitrate hydrate In(NO3)3˙xH2O was dissolved in deionized water at a concentration of 0.1 mol / L, and magnetically stirred at room temperature for 8 hours to form a clear and transparent indium oxide precursor solution. The heavily doped low-resistance silicon substrate was submerged in deionized water, acetone and isopropanol for ultrasonic cleaning for 10 min, and after the substrate was blown dry with a nitrogen gun, the surface of the substrate was further cleaned by plasma cleaning.

[0029] After cleaning, an atomic layer deposition equipment was used to prepare a 11nm high-dielectric aluminum oxide film on a silicon substrate. After the aluminum oxide film was cleaned with oxygen plasma for 70 seconds, the indium oxide precursor solution was spin-coated by spin coating immediately. On the aluminum oxide film, the rotational speed of spin coating is 5000rpm, and the time is 25s. After the spin coating, the sample was preheated on a heating plate at 150°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com