Composite multifunctional OLED electrode and preparation method thereof

A multi-functional, electrode technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of metal nanowires that are difficult to balance light transmission and conductivity, achieve good hole/electron injection capabilities, and solve light transmission problems. properties and electrical conductivity, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

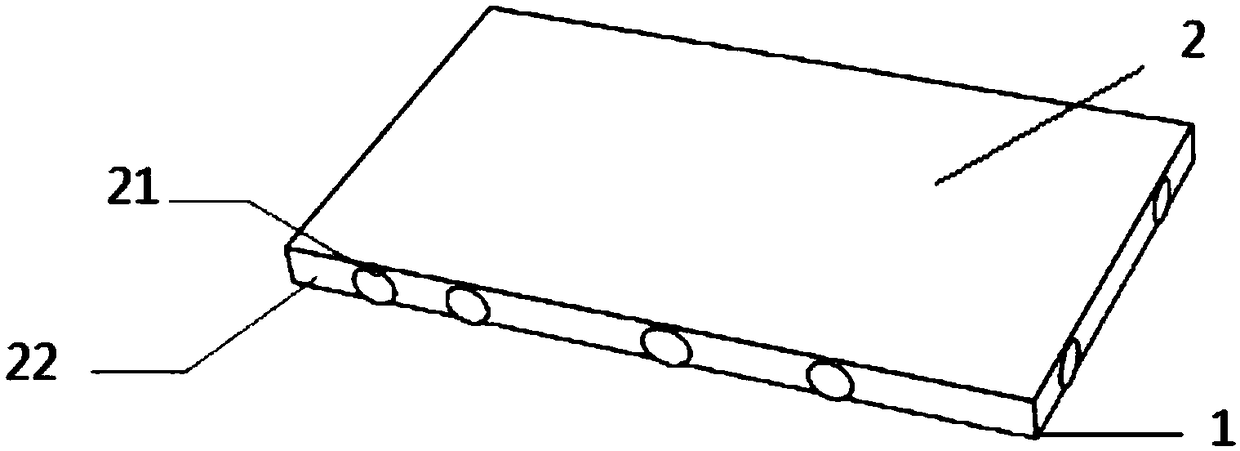

[0030] figure 1 It is a schematic structural diagram of a composite multifunctional OLED electrode according to an embodiment of the present invention,

[0031] Such as figure 1 As shown, the composite multifunctional OLED electrode provided by the embodiment of the present invention includes a flexible substrate 1 and a metal nanowire-photoelectric polymer hybrid layer 2 grown on the flexible substrate; the metal nanowire-photoelectric polymer hybrid layer includes Metal nanowires 21 and optoelectronic polymer materials 22; spin coating a layer of optoelectronic polymer materials 22 on the metal nanowires 21, so that the optoelectronic polymer materials 22 fill the gaps between the metal nanowires 21 Inside.

[0032] Preferably, the metal nanowires 21 are silver nanowires with a diameter of 80 nm and a length of 5 μm. The optoelectronic polymer material 22 is poly 2-(2-ethylhexyloxy)-5-methoxyphenyl acetylene solution, referred to as MEH-PPV solution in English, and the op...

Embodiment 3

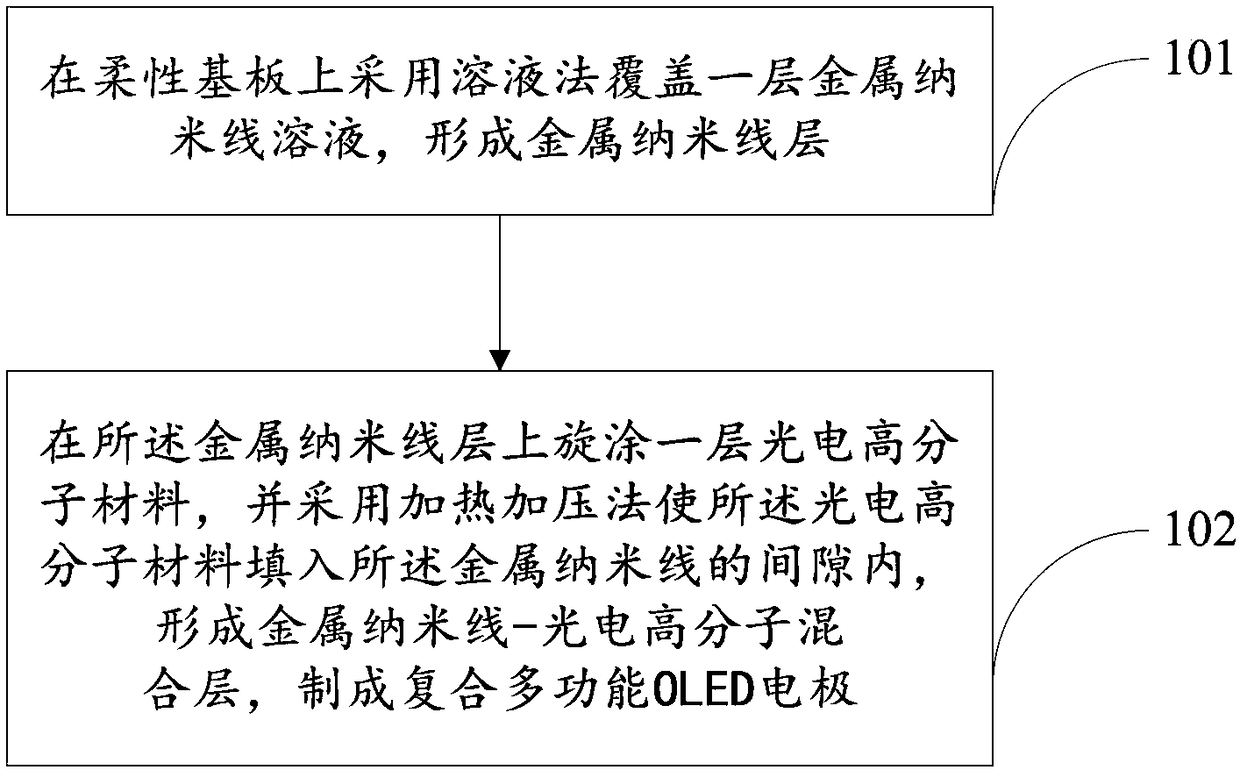

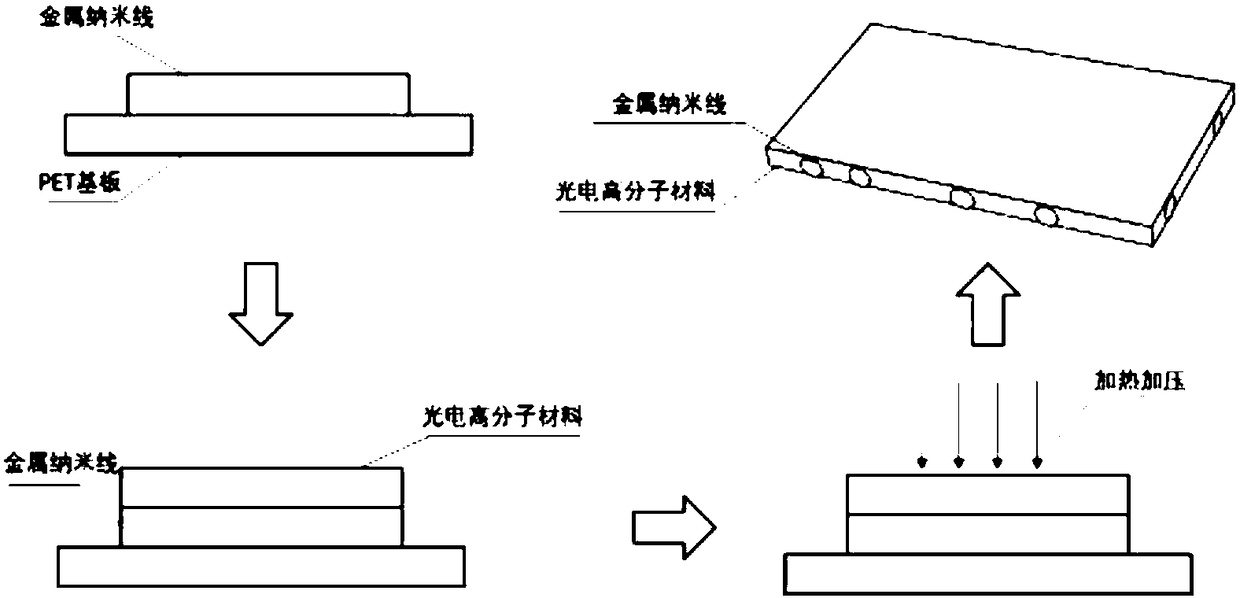

[0041] image 3 It is a schematic diagram of the preparation process of the composite electrode based on the silver nanowire electrode and the photoelectric polymer material MEH-PPV according to the embodiment of the present invention, as image 3 As shown, the embodiment of the present invention provides a method for preparing a composite electrode based on a silver nanowire electrode and an optoelectronic polymer material MEH-PPV, including:

[0042] First, silver nanowires with a particle diameter of 80 nm and a length of 50 μm are dispersed in an ethanol solution to form a silver nanowire solution, and the mass fraction of the ethanol solution is 1 wt%.

[0043] Secondly, the silver nanowire solution was spin-coated on the flexible PET substrate, and the average film thickness was controlled at about 200nm, followed by annealing at 100°C for 20 minutes.

[0044] Furthermore, the MEH-PPV solution is spin-coated on the silver nanowire film, the solvent is toluene, the film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com