Conductive carbon black modified silicon dioxide aerogel loaded sulfur composite positive electrode material and preparation method thereof

A composite cathode material, conductive carbon black technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor capacity performance and cycle stability, low coulomb efficiency, etc., to achieve excellent capacity performance and cycle stability, improvement ratio Energy density, the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a second aspect, the present invention provides a method for preparing a conductive carbon black-modified silica airgel-loaded sulfur composite positive electrode material, the method comprising the following steps:

[0037] (1) uniformly mixing conductive carbon black-modified silica airgel with elemental sulfur to obtain a mixture; and

[0038] (2) Under the condition of airtight and inert gas protection, the mixture obtained in step (1) is heated at 115°C to 160°C (such as 115°C, 120°C, 125°C, 130°C, 135°C, 140°C, 145°C, 150° C., 155° C. or 160° C.) for heat treatment to prepare the conductive carbon black modified silica airgel loaded sulfur composite cathode material.

[0039] In the present invention, the inert gas may be, for example, nitrogen gas, argon gas or helium gas, preferably nitrogen gas; Liquid form enters conductive carbon black-modified SiO 2 The internal pores of the airgel are obtained to obtain the conductive carbon black modified silica airge...

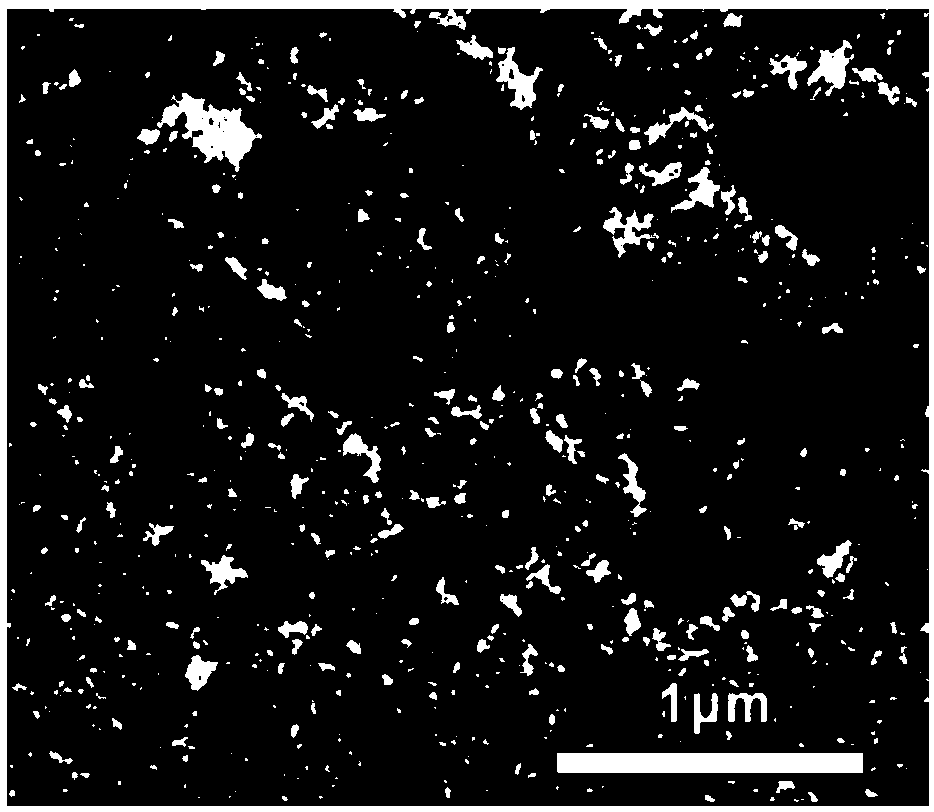

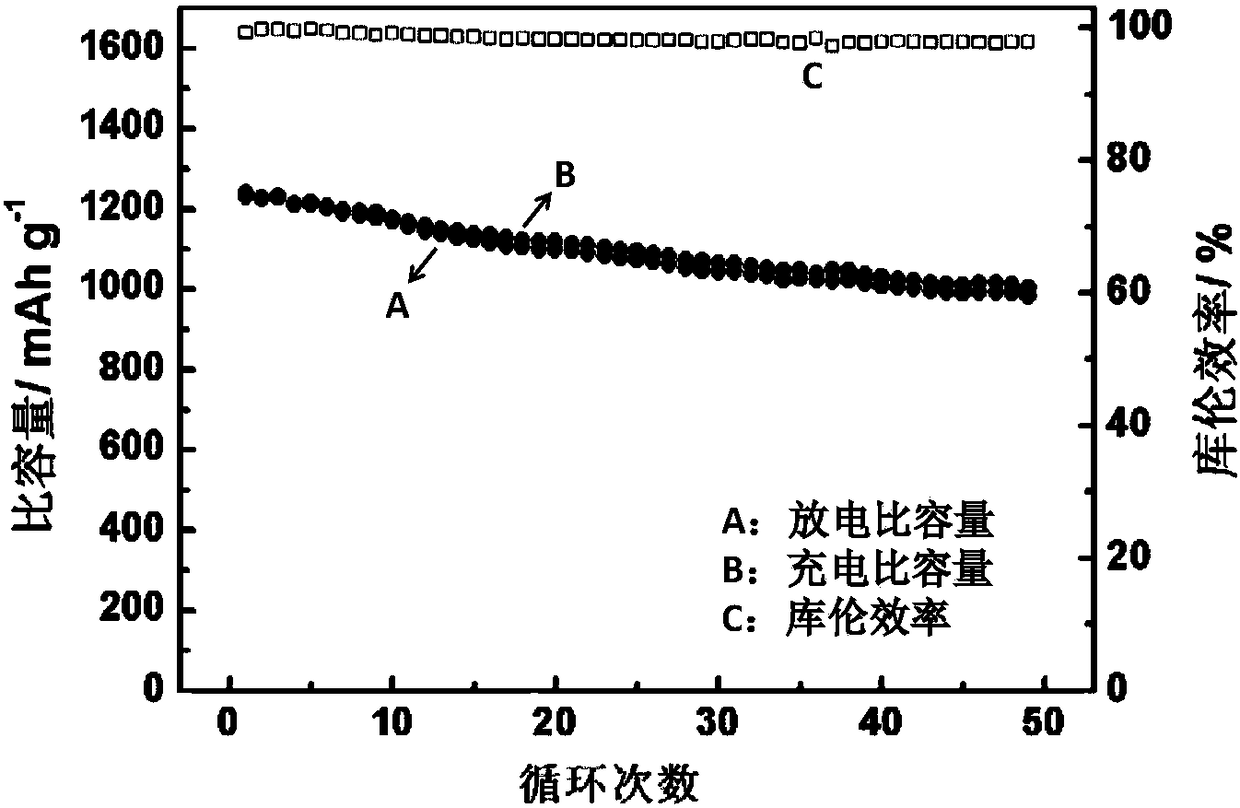

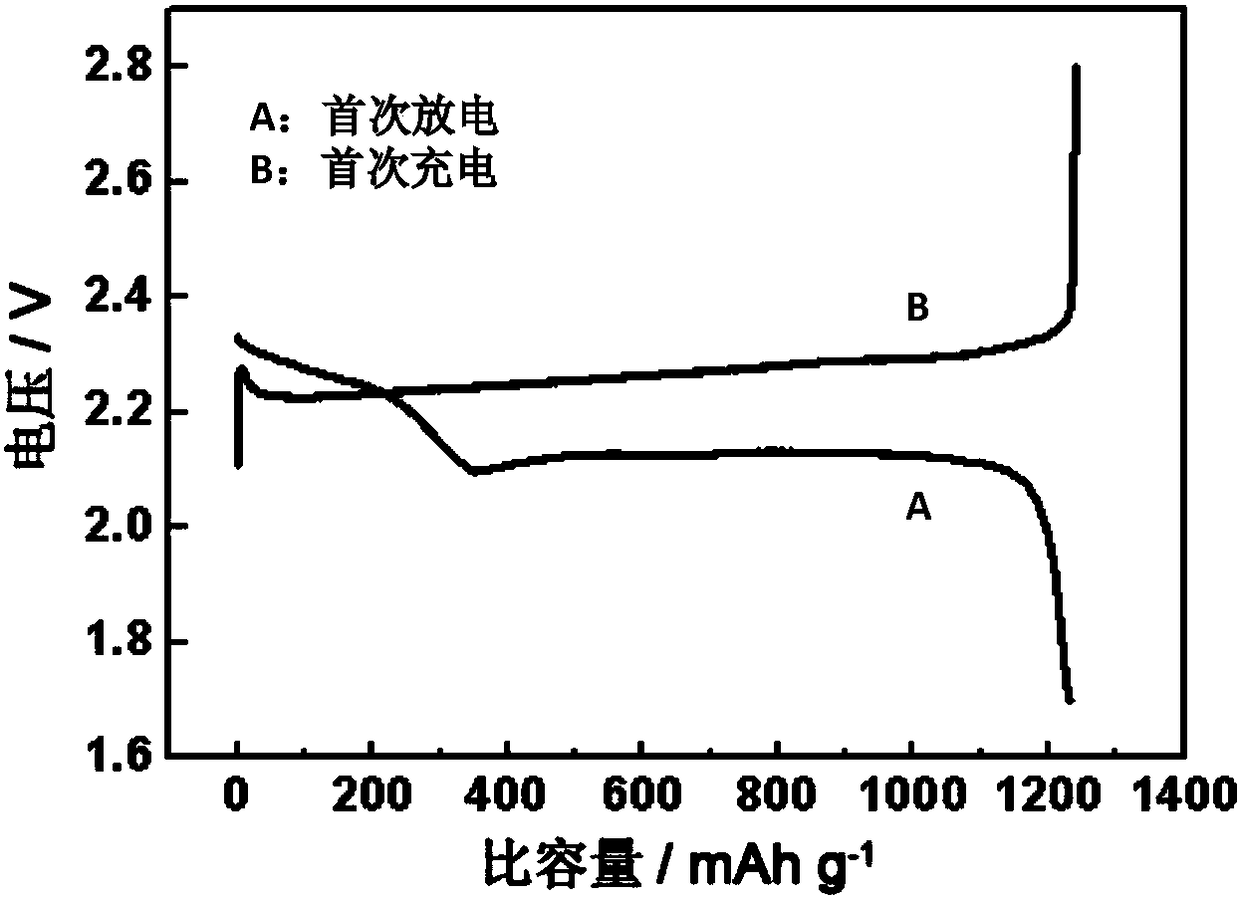

Embodiment 1

[0061] ①Ethyl orthosilicate, ethanol, deionized water and sodium lauryl sulfate are prepared into a uniform mixed solution, wherein the mass ratio of ethyl orthosilicate, ethanol and deionized water is 3:5:2, twelve The concentration of sodium alkyl sulfate in the mixture is 5×10 - 3 mol / L; then the conductive carbon black with a particle size of 50nm is added to the mixed solution, and stirred at 200rpm for 1h to obtain a mixed material, wherein the amount of conductive carbon black added is the same as the quality of tetraethyl orthosilicate in the mixed solution The ratio is 1:19.7; then add a hydrochloric acid solution with a concentration of 1 mol / L to the mixture, the amount added is 4% of the mass of the mixture, then stir at 150rpm for 10min and then stand still to obtain a wet gel; Then soak the obtained wet gel in ethanol, tetraethyl orthosilicate and n-hexane respectively for 24 hours to perform solvent exchange and aging steps to obtain a gel; finally, place the o...

Embodiment 2

[0066] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0067] In ①: the mass ratio of ethyl orthosilicate, ethanol and deionized water is 3:2:2; the particle size of conductive carbon black is 30nm, and the mass ratio of conductive carbon black addition to ethyl orthosilicate in the mixed solution is 1: 66; the addition amount of hydrochloric acid solution is 5% of the mass of the mixture; obtain conductive carbon black modified silica airgel with conductive carbon black doping amount of 5%.

[0068] In ②: Sublimated Sulfur Powder and Conductive Carbon Black Modified SiO 2 The mass ratio of airgel is 1:1; the heat treatment temperature is 150°C; the mass percentage of elemental sulfur is 50% conductive carbon black modified silica airgel loaded sulfur composite positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com