Systems and methods for producing gastrointestinal tissues

A main body and cell technology, applied in biochemical equipment and methods, methods of supporting/immobilizing microorganisms, tissue regeneration, etc., can solve problems such as high morbidity and mortality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

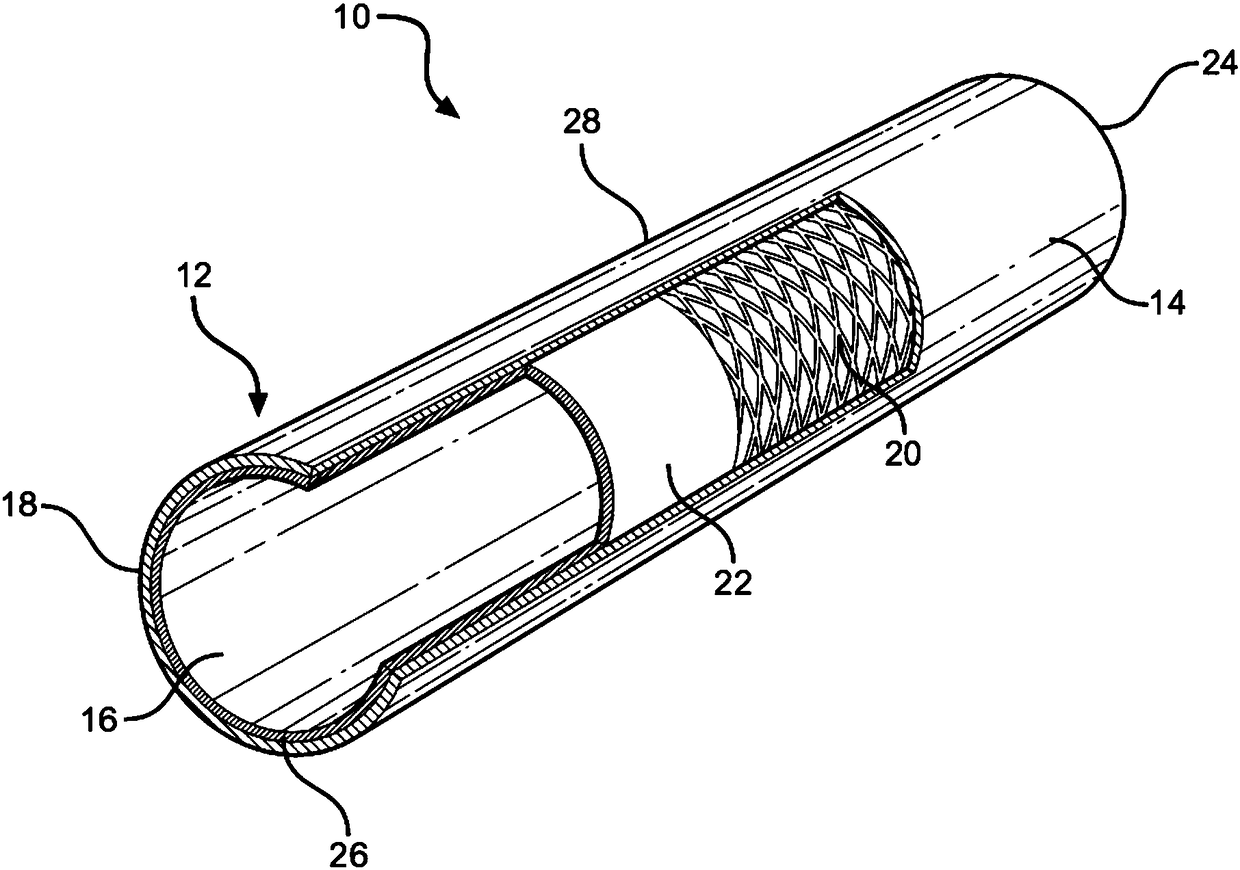

[0110] Example I: Esophageal Stent

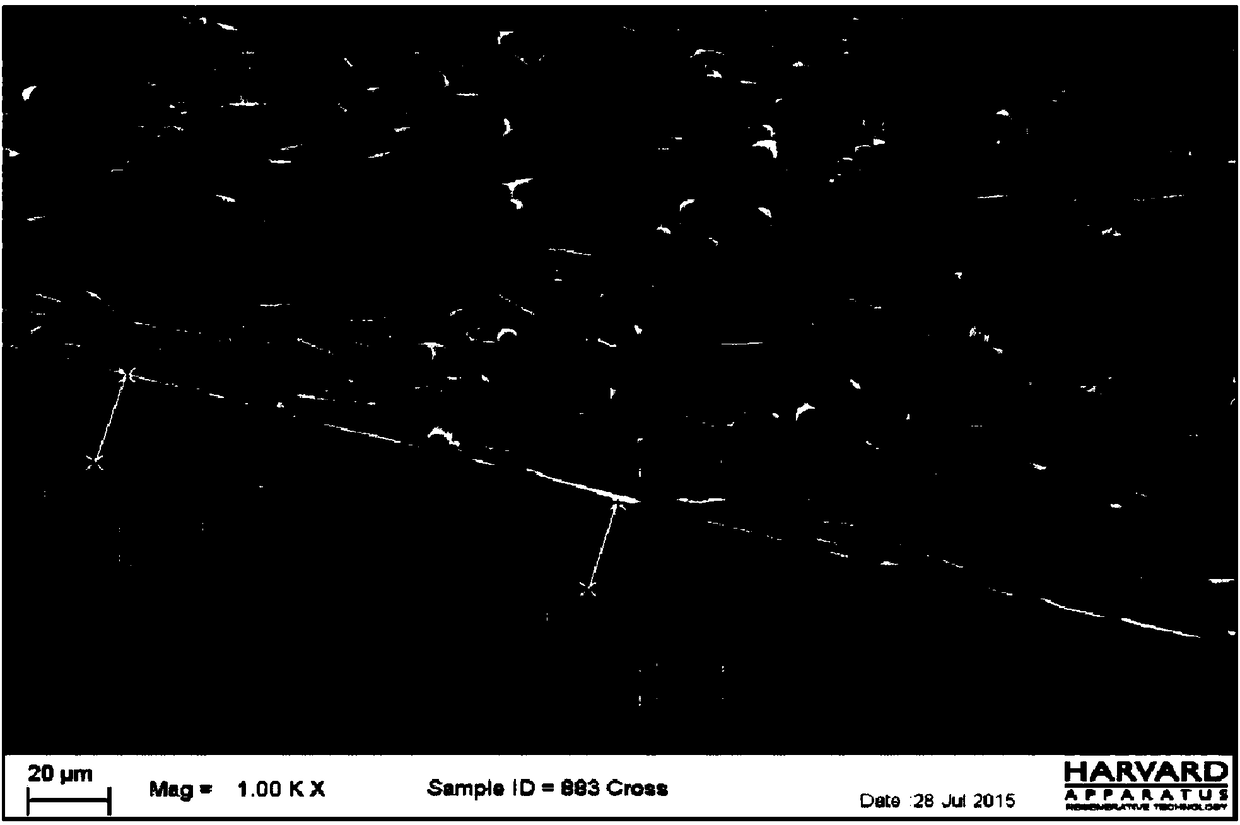

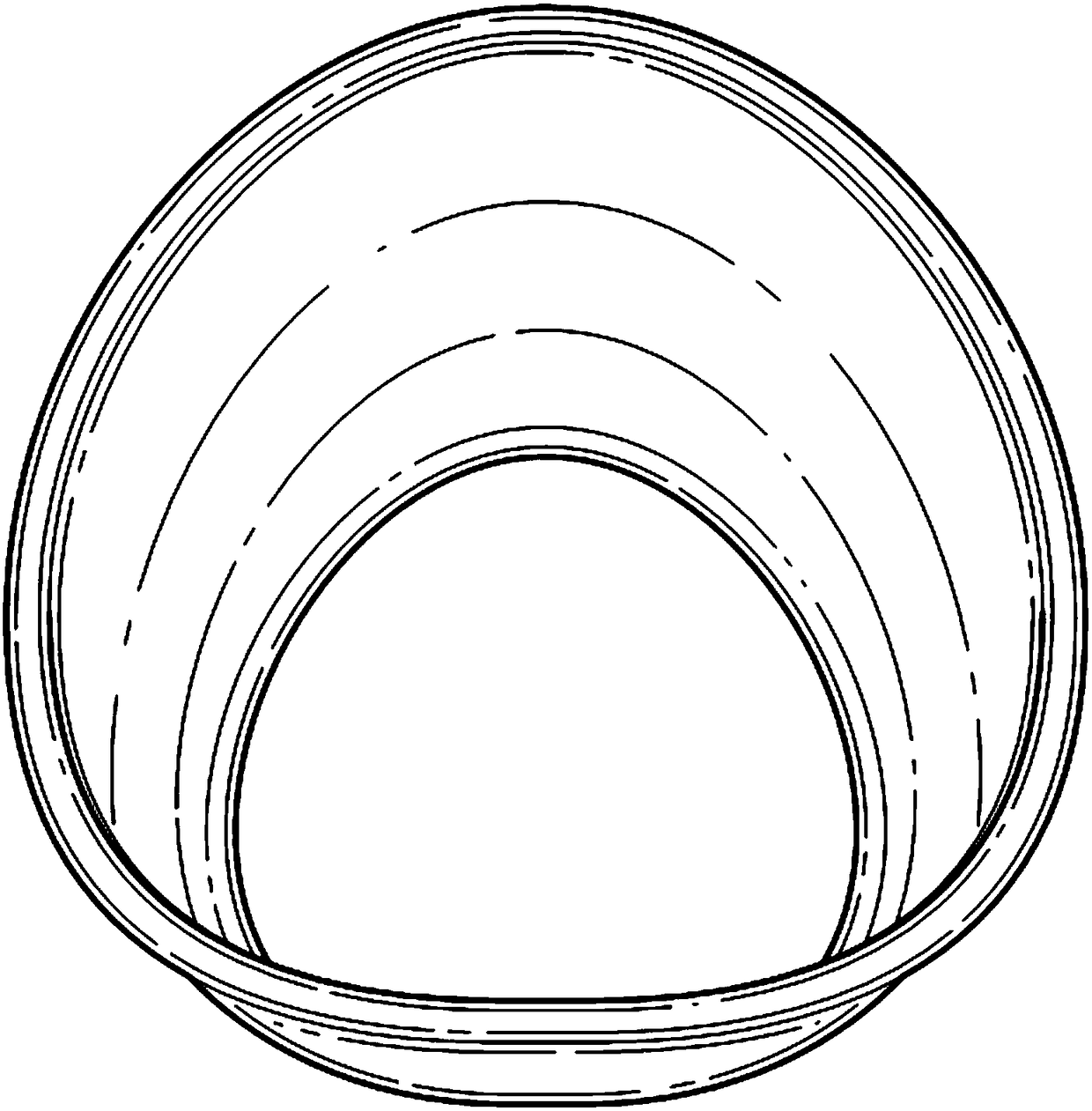

[0111] like Figure 1A As shown, a synthetic esophageal stent comprising three layers of material was prepared. A first layer of polyurethane (PU) is deposited by electrostatic atomization onto a metal mandrel, and then a braided material is deposited on top of the first PU layer. The second PU layer is then deposited by electrospinning. The formed scaffold is then removed from the mandrel. Each scaffold defines a tubular structure having three layers (inner electrostatically atomized layer, outer electrospun layer, and braid layer sandwiched between the inner electrostatically atomized layer and outer electrospun layer) the wall. The physical dimensions of the scaffolds were determined by scanning electron microscopy (SEM). The average scaffold wall thickness is about 500 microns. Figure 1B A non-limiting SEM view of a cross-section of the wall is shown in . Figure 1C A non-limiting view of a cross-section of a tubular stent is sh...

Embodiment II

[0120] Example II: Esophageal Implantation

[0121] like Figure 1A As shown, a synthetic esophageal stent comprising a three-layer material with an outer electrospun layer of polycarbonate-polyurethane prepared by dissolving in hexafluoroisopropanol (HFIP, DuPont, Wilmington , Delaware, USA) in 12% w / v polycarbonate polyurethane solution deposited. The electrospinning device used was purchased from IME Technologies, Geldrop (Netherlands), the Netherlands. Electrospun fibers were collected on a target aluminum mandrel rotating at 800 rpm and placed 22 mm from the syringe tip to deposit isotropic fibers, resulting in scaffolds with an average wall thickness of 500 μm. The scaffolds were dried in vacuum Removal of residual solvent. Then by a low-pressure plasma system (Diener Tetra 150-LF-PC-D), plasma treatment is carried out to the support with ethylene and oxygen gas of 2 forward cycles. The support is carried out gamma sterilization (Think Teri Corporation (STERIS), Northb...

Embodiment III

[0147] Example III - Other gastrointestinal implants

[0148] The procedures described in Example I and Example II may be performed instead in regions of the gastrointestinal tract confined to the rectum. The results were similar to those outlined previously.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com