Method for preparing gold nanometer spherical shells with polydopamine as template

A technology of polydopamine and nanospheres, which is applied in the field of materials, can solve the problems of nanomaterials such as environmental pollution, complex process, and high mechanical strength, and achieve the effects of simple molecular composition, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

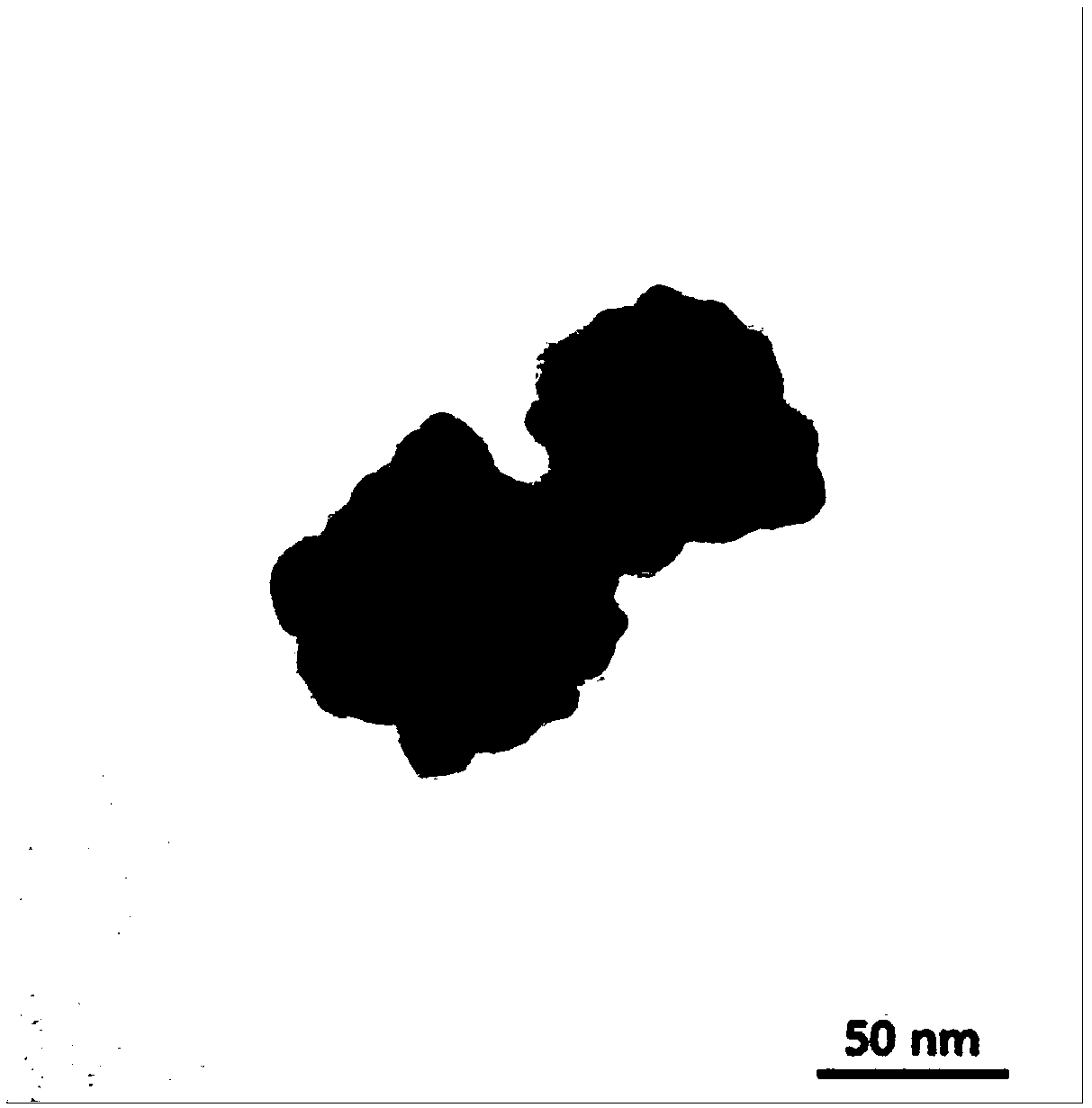

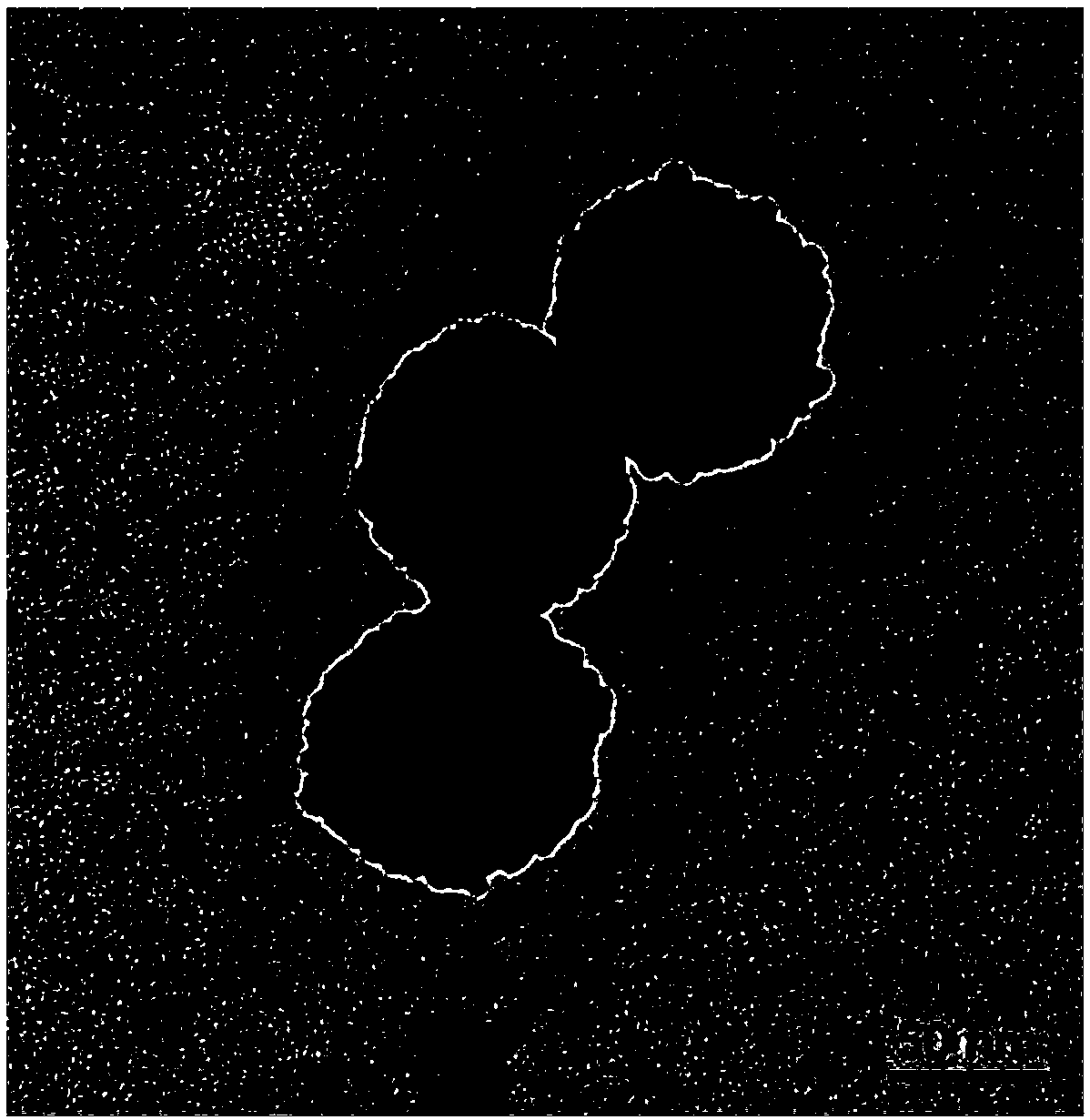

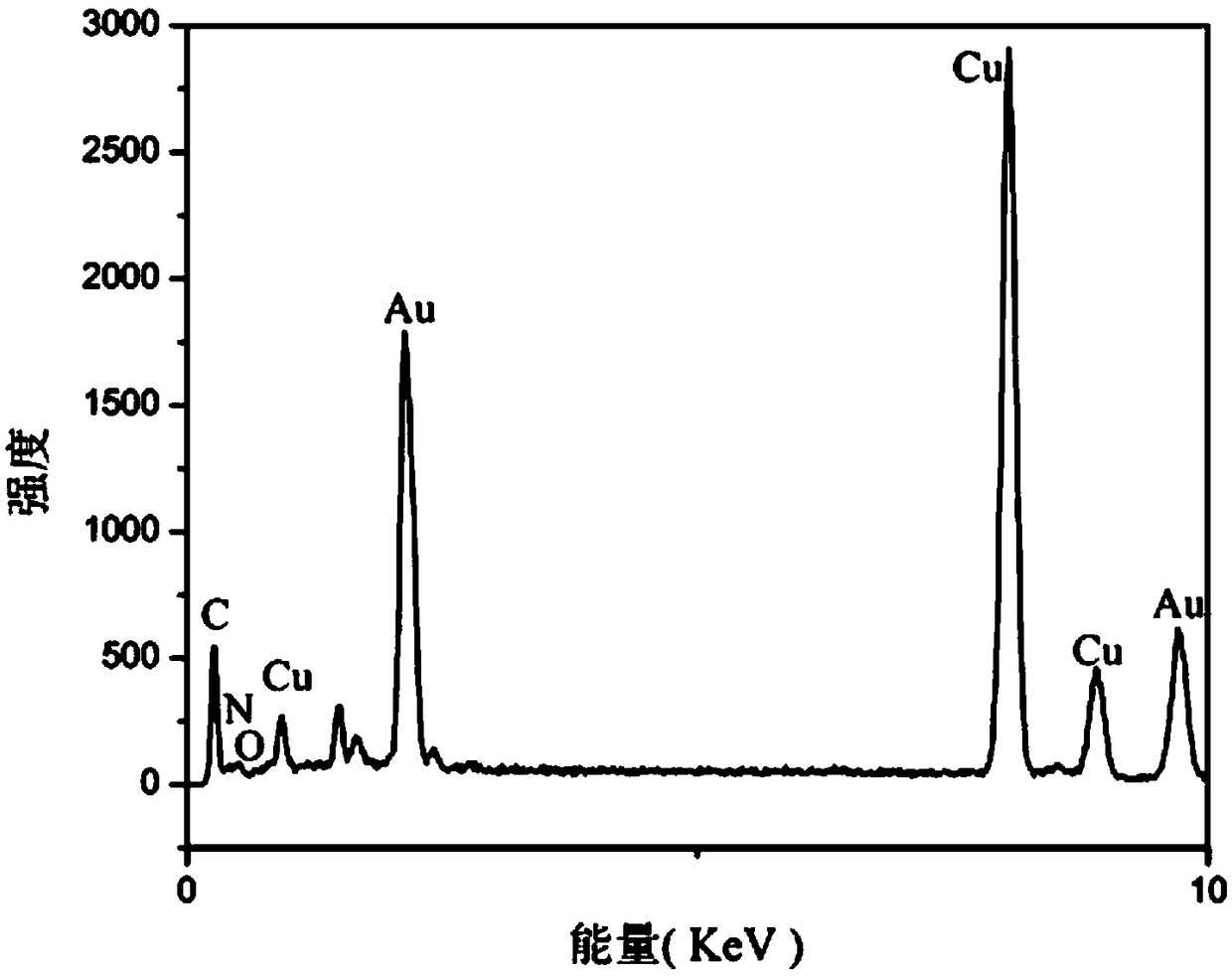

Embodiment 1

[0023] Take 5 mg of dopamine hydrochloride (produced by Shanghai Aladdin Biochemical Technology Co., Ltd.), and dissolve it in 10 mL of Tris hydrochloric acid buffer solution with pH 8.5 to obtain a dopamine hydrochloride solution with a concentration of 0.5 mg / mL; place the configured solution on a magnetic stirrer Stir for 1 hour at 25°C in the dark; then use an ultrasonic cell pulverizer to sonicate for 10 minutes with an ultrasonic power of 500 W. After ultrasonication, centrifuge at 8,000 rpm for 10 minutes to take the supernatant, and centrifuge the supernatant at 14,000 rpm to get the precipitate. , after the precipitate was washed once by centrifugation with deionized water, 0.35 mg of the precipitate was resuspended in 5 mL of pH 2 hydrochloric acid solution; 200 μL of the above solution was added to 200 μL of a gold chloride solution with a concentration of 2 mM and pH 2 (Shanghai West Asia Reagent Co., Ltd.), mix it evenly, put it into a double-layer air bath shaker,...

Embodiment 2

[0026] Take 7.5 mg of dopamine hydrochloride (produced by Shanghai Aladdin Biochemical Technology Co., Ltd.), dissolve it in 15 mL of Tris hydrochloric acid buffer solution with pH 8.5, and obtain a concentration of 0.5 mg / mL dopamine hydrochloride solution; place the above solution in a magnetic stirrer Stir for 1.5 hours at a temperature of 20°C in the dark; then use an ultrasonic cell pulverizer to sonicate for 10 minutes, with an ultrasonic power of 500W, and centrifuge at 8,000rpm for 10 minutes to take the supernatant, and centrifuge the supernatant at 14,000rpm to take the precipitate After the precipitate was centrifuged and washed twice with deionized water, 0.525 mg of the precipitate was resuspended in 7.5 mL of pH 2 hydrochloric acid solution; 200 μL of the above polydopamine solution was added to 200 μL of gold chloride with a concentration of 4 mM and pH 2 Solution (Shanghai West Asia Reagent Co., Ltd.), mix well, put it into a double-layer air bath shaker, contro...

Embodiment 3

[0032] Take 10 mg of dopamine hydrochloride (produced by Shanghai Aladdin Biochemical Technology Co., Ltd.), dissolve it in 20 mL of Tris hydrochloric acid buffer solution with pH 8.5, and obtain a concentration of 0.5 mg / mL dopamine hydrochloride solution; place the above solution on a magnetic stirrer , stirred at 15°C for 2 hours in the dark; then sonicated with an ultrasonic cell pulverizer for 10 minutes, with an ultrasonic power of 500 W, and centrifuged at 8,000 rpm for 10 minutes to take the supernatant, and then centrifuged the supernatant at 14,000 rpm to get the precipitate. After the precipitate was washed by centrifugation with deionized water for 3 times, 0.7 mg of the precipitate was resuspended in 10 mL of pH 2 hydrochloric acid solution; 200 μL of the above polydopamine solution was added to 200 μL of gold chloride solution with a concentration of 6 mM and pH 2 (Shanghai West Asia Reagent Co., Ltd.), mix well, then put it into a double-layer air bath shaker, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com