A method for preparing high-strength carbon nanotube films using thiol-alkene click reaction

A carbon nanotube film, olefin click technology, applied in the direction of carbon nanotubes, nanocarbons, etc., can solve the problems of large difference in axial and radial properties, discrete properties, and large discreteness, and improve strength and performance stability. , Improve the density and strength, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

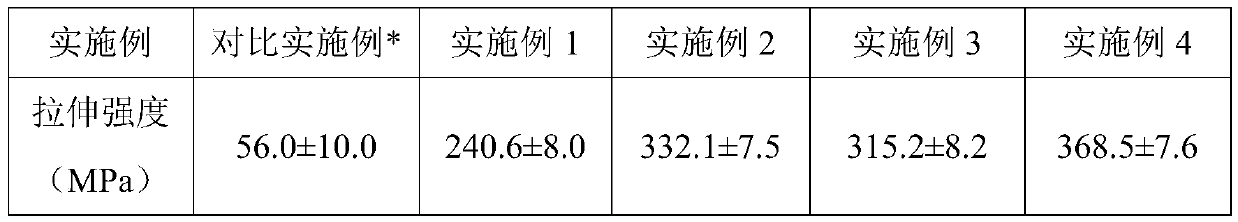

Examples

Embodiment 1

[0031] Embodiment 1 A kind of method utilizing mercaptan-alkene click reaction to prepare high-strength carbon nanotube film, its steps are as follows:

[0032] Diethylene glycol di(3-mercaptopropionate) 10g (DEMP), 0.005g 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholine Base)-1-acetone and 5g tetrahydrofuran are mixed uniformly to form a mixed solution; under room temperature, 0.1g of a carbon nanotube film with a thickness of 20-25 microns is soaked in the above mixed solution for 30 minutes; then the carbon nanotube film is taken out and placed in the At room temperature, irradiate it with a UV lamp with a power of 3000W for 20 minutes to carry out the thiol-alkene click reaction; wash the residues on the surface of the carbon nanotube film after irradiation twice with chloroform, and remove the residues not involved in the click reaction. The removal of mercaptans, etc.; the rinsed carbon nanotube film was dried in a vacuum oven at 60°C for 1.5 hours, and then the dried f...

Embodiment 2

[0033] Embodiment 2 A kind of method utilizing mercaptan-alkene click reaction to prepare high-strength carbon nanotube film, its steps are as follows:

[0034] 5g tris (2-hydroxyethyl) isocyanurate tris (3-mercaptopropionic acid) ester (THMP), 0.03g p-aminopropiophenone and 10g dioxane are mixed uniformly to form a mixed solution; under room temperature conditions, Soak 0.1g of a carbon nanotube film with a thickness of 20-25 microns in the above mixed solution for 5 minutes; then take out the carbon nanotube film, and at room temperature, use a UV lamp with a power of 800W to illuminate it for 40 minutes to carry out Thiol-alkene click reaction; wash the residues on the surface of the carbon nanotube film after irradiation with methyl ethyl ketone three times to remove thiols that did not participate in the click reaction; place the washed carbon nanotube film at 80°C Dry in a vacuum oven for 2 hours, then carry out mechanical rolling (distance between rollers is 20 microns)...

Embodiment 3

[0035] Embodiment 3 A kind of method utilizing mercaptan-alkene click reaction to prepare high-strength carbon nanotube film, its steps are as follows:

[0036]Mix 1g of trimethylolpropane tris(3-mercaptopropionate) (TMMP), 0.01g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 1g of acetone to form a mixed solution; , soak 0.1g of a carbon nanotube film with a thickness of 20-25 microns in the above mixed solution for 20 minutes; then take out the carbon nanotube film, and at room temperature, use a UV lamp with a power of 1500W to illuminate it for 60 minutes, Carry out the thiol-alkene click reaction; wash the residue on the surface of the carbon nanotube film after irradiation with acetone twice to remove the thiols that did not participate in the click reaction; place the rinsed carbon nanotube film at 40°C Dry in a vacuum oven for 1 hour, then carry out mechanical rolling (distance between rollers is 20 microns) 3 times to the dried film to obtain a high-strength carbon na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com