Preparation method of silicon-containing HVPB (high vinyl polybutadiene)

A high-vinyl polybutadiene and butadiene technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of poor compatibility of silica and high Mooney viscosity, and achieve good dispersion and door-to-door Effects of low nylon viscosity and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

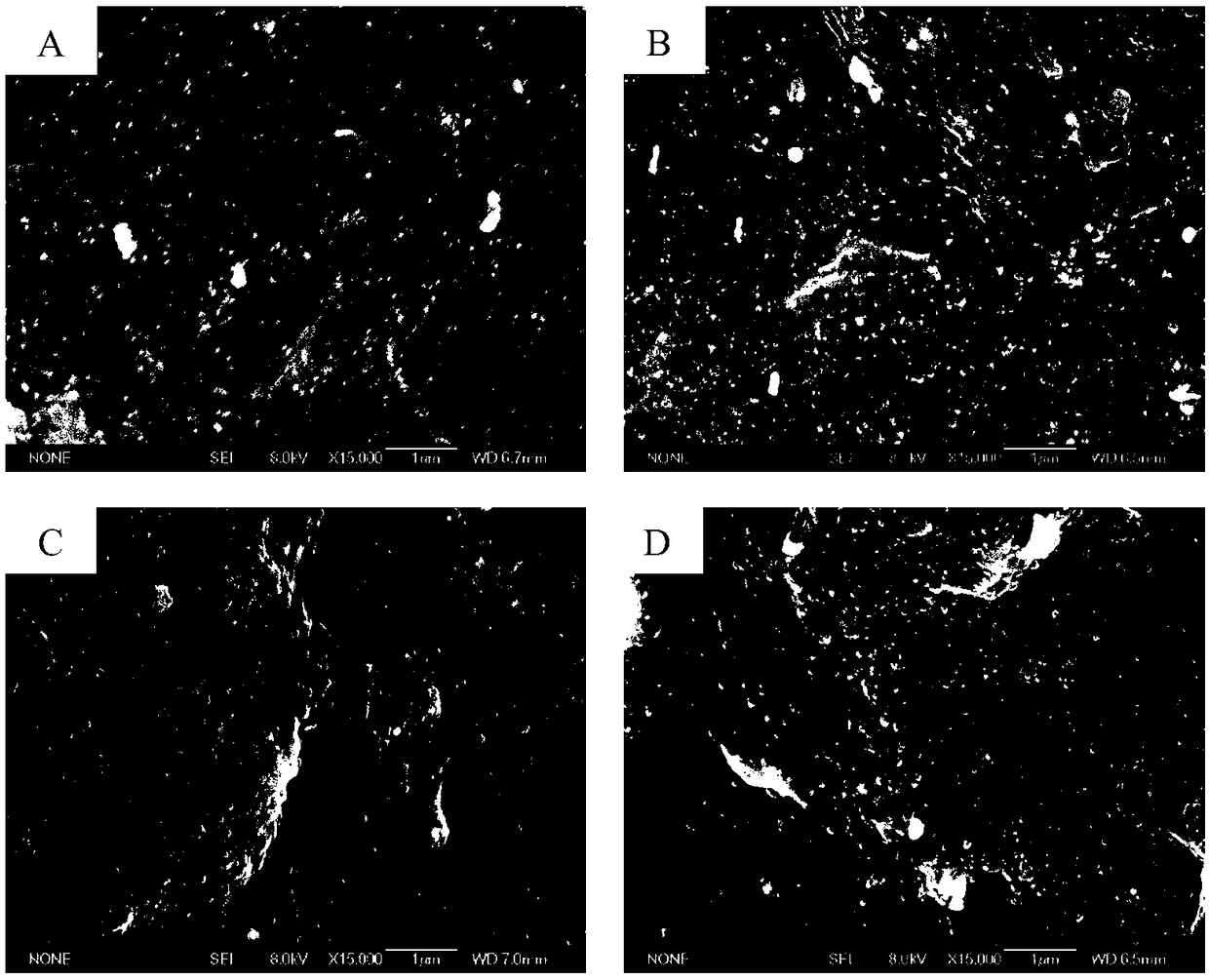

[0038] This preparation example is used to illustrate the silicon-containing macromer provided by the present invention and its preparation method.

[0039] Add 100 mL of 0.14 g / mL butadiene (abbreviated as Bd) n-hexane solution to a 500 mL reaction flask successively under nitrogen protection, heat to 60° C., add 1.6 mL of 1.6 M initiator n-butyllithium (referred to as n-BuLi), after two hours of polymerization, add 154g of octamethylcyclotetrasiloxane (abbreviated as D4) and 25mL of accelerator N,N-dimethylamide (abbreviated as DMF), and polymerize for another 2 hours to prepare the PB segment The molecular weight is 7000, the total molecular weight is 1.6×10 4 silicon-containing macromers.

[0040] Implementation column 1

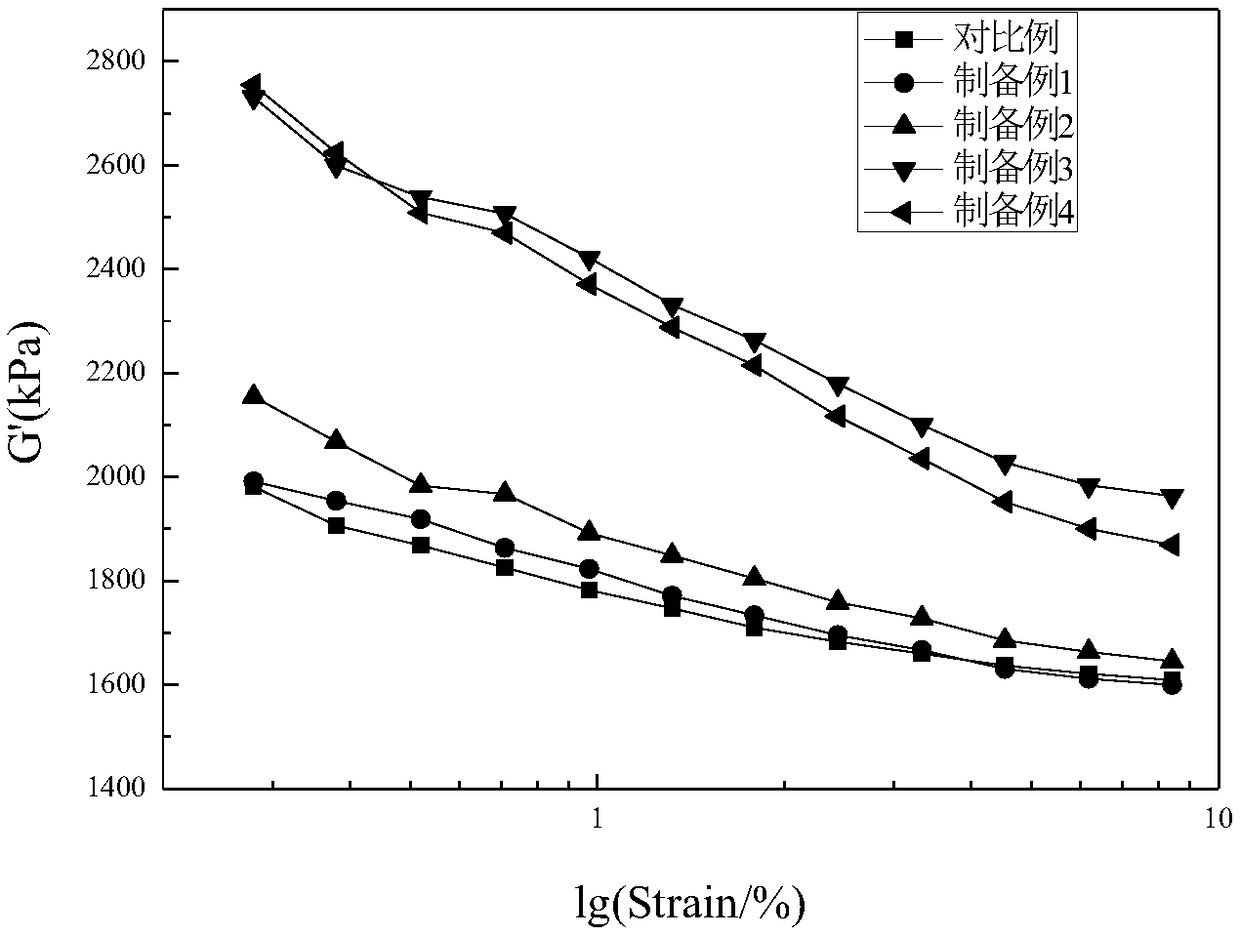

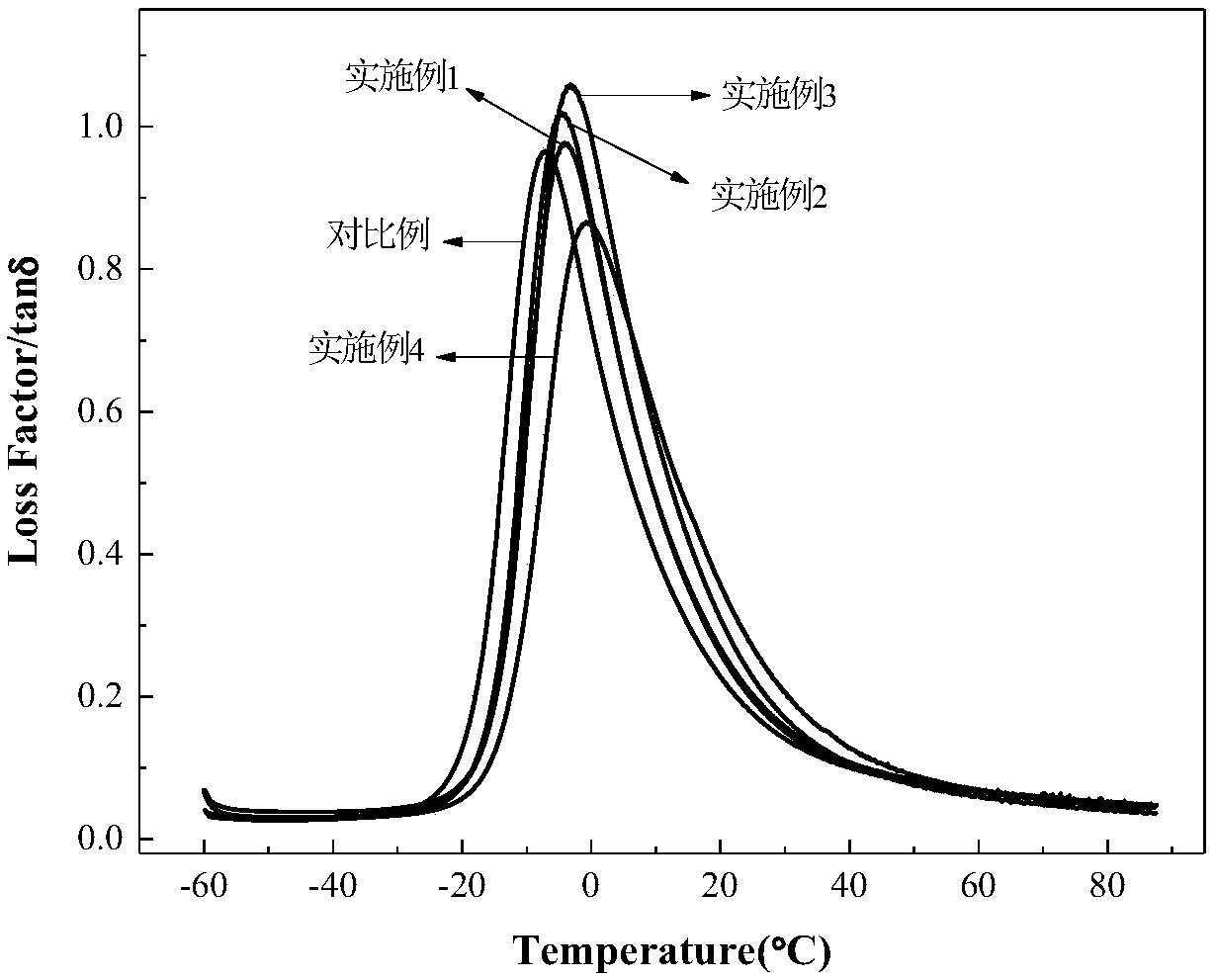

[0041] In the 3L polymerization kettle under nitrogen atmosphere, add 2.5L of 140g / L butadiene n-hexane solution successively, 3.5g silicon-containing macromer, take the amount of butadiene as the benchmark, the amount of silicon-containing macromer 1...

Embodiment 2

[0043] Prepared by the same method as in Example 1, the difference is that, based on the amount of butadiene, the amount of silicon-containing macromers is 3% by weight, and Si-g- HVBR3 vulcanizate, its properties are listed in Table 2.

Embodiment 3

[0045] Prepared by the same method as in Example 1, the difference is that, based on the amount of butadiene, the amount of silicon-containing macromers is 5% by weight, and Si-g- HVBR5 vulcanizate, its properties are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com