Preparation method of Zn-N compound doped titanium dioxide nanotube array membrane with visible light activity

A nanotube array and compound doping technology, which is applied in the field of semiconductor nanomaterial modification, can solve the problems of unfavorable photocatalytic reaction, etc., and achieve the effect of high specific surface area and quantum transmission efficiency, high visible light photocatalytic performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

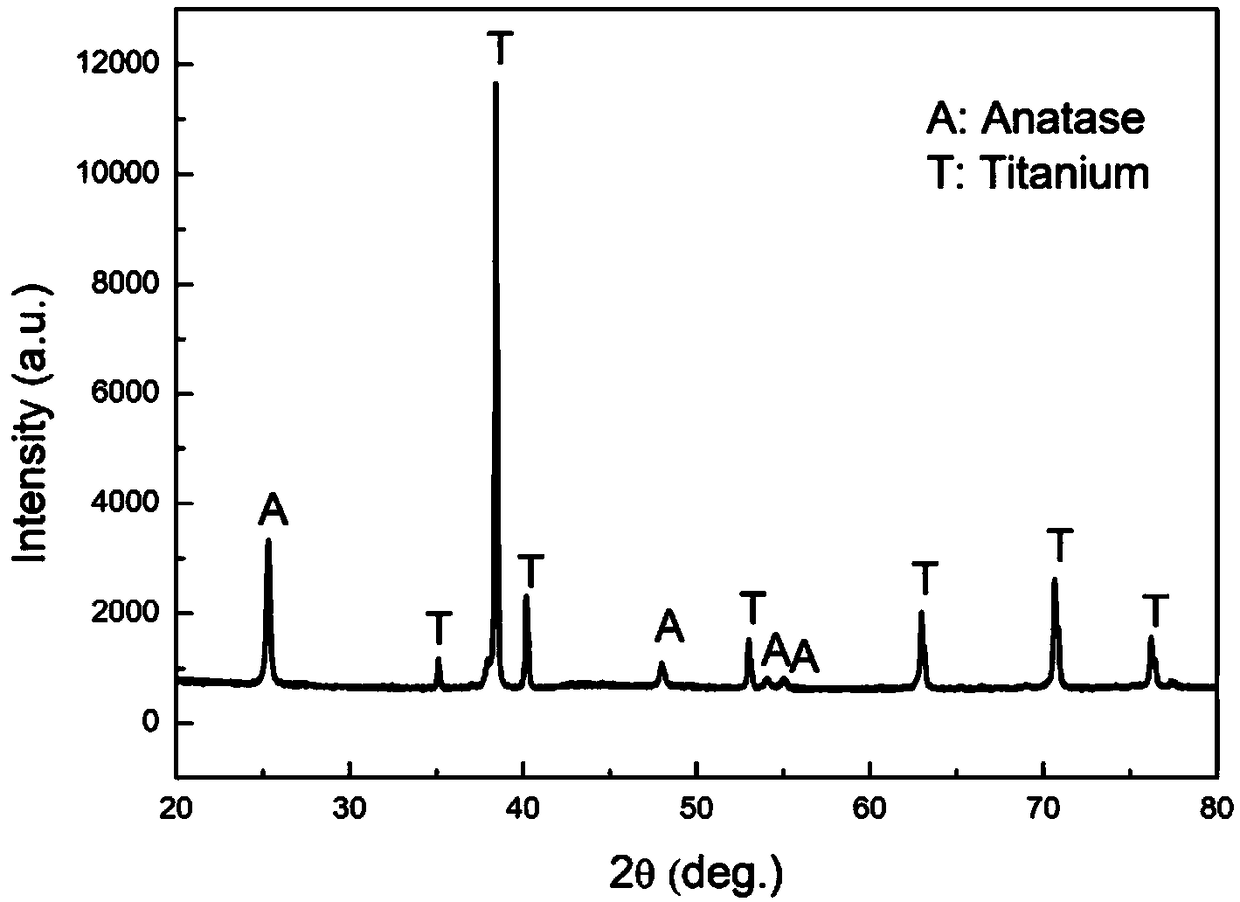

[0034] (1) Place the pure titanium plate in HF / HNO 3 / H 2 O (volume ratio 1:4:5) polishing solution for 20 s to remove the dense oxide layer on the surface. Then use ethanol and deionized water to ultrasonically clean them for 15 minutes respectively, take them out and wash them, dry them in the air and store them in a desiccator for later use.

[0035] (2) Configure the electrolyte: the electrolyte is composed of 0.55 wt% NH 4 F, 10 wt% H 2 O and ethylene glycol (the remainder) are mixed.

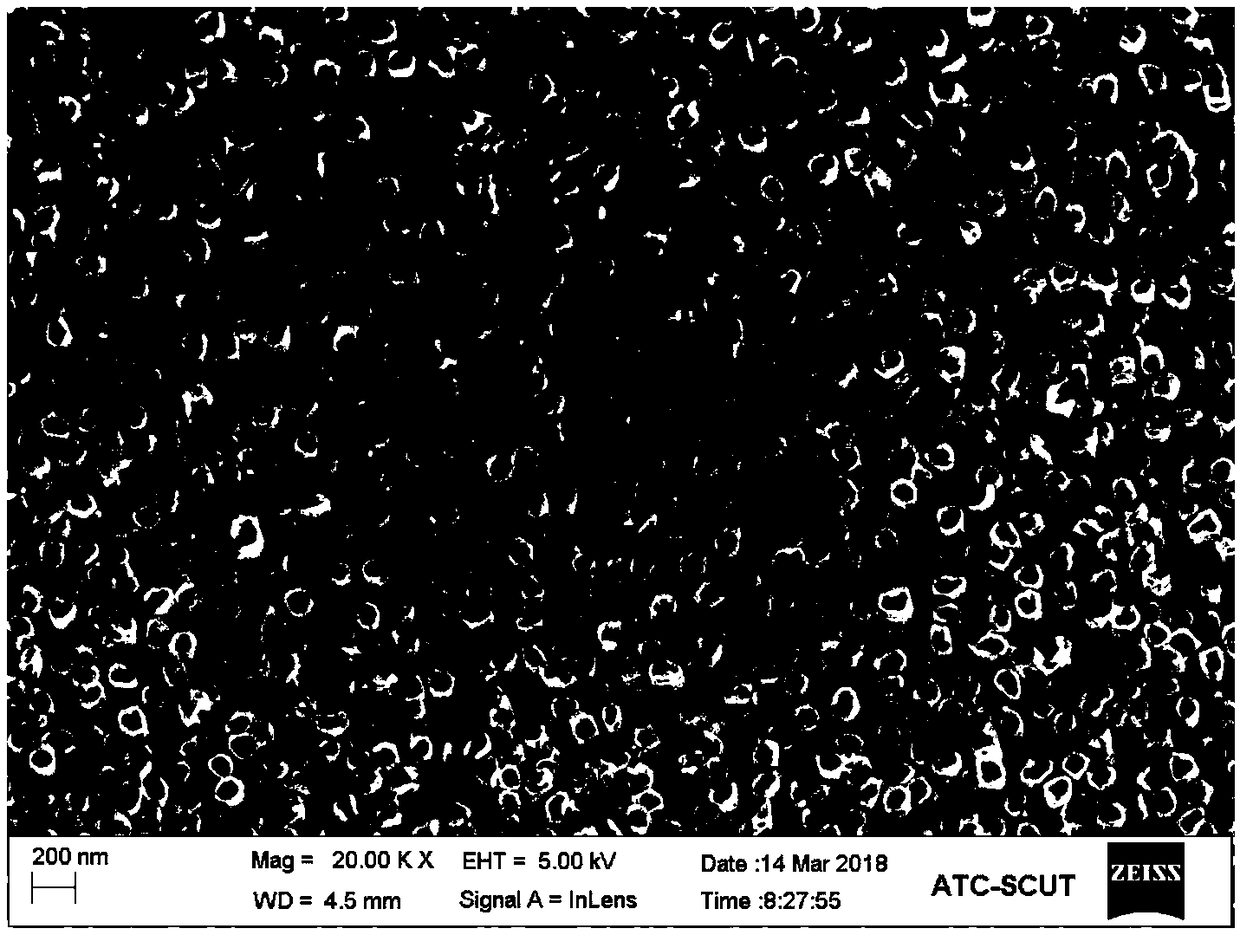

[0036] (3) Using the electrochemical anodizing method, the cleaned titanium plate was used as the anode, the platinum plate was used as the cathode, and the distance between the two electrodes was 20 mm, and the titanium plate was anodized under a DC voltage of 30 V for 1 h. After the reaction, the prepared samples were cleaned with deionized water and dried naturally.

[0037] (4) With absolute ethanol as solvent and anhydrous zinc chloride as solute, prepare 0.001 M zinc chloride etha...

Embodiment 2

[0040] (1) Place the pure titanium plate in HF / HNO 3 / H 2 O (volume ratio 1:4:5) polishing solution for 20 s to remove the dense oxide layer on the surface. Then use ethanol and deionized water to ultrasonically clean them for 15 minutes respectively, take them out and wash them, dry them in the air and store them in a desiccator for later use.

[0041] (2) Configure the electrolyte: the electrolyte is composed of 0.55 wt% NH 4 F, 20 wt% H 2 O and ethylene glycol (the remainder) are mixed.

[0042] (3) Using the electrochemical anodizing method, the cleaned titanium plate was used as the anode and the platinum plate was used as the cathode, with a distance of 30 mm between the two electrodes, and the titanium plate was anodized under a DC voltage of 40 V for 2 h. After the reaction, the prepared samples were cleaned with deionized water and dried naturally.

[0043] (4) With absolute ethanol as solvent and anhydrous zinc chloride as solute, prepare 0.003 M zinc chloride e...

Embodiment 3

[0046] (1) Place the pure titanium plate in HF / HNO 3 / H 2 O (volume ratio 1:4:5) polishing solution for 20 s to remove the dense oxide layer on the surface. Then use ethanol and deionized water to ultrasonically clean them for 15 minutes respectively, take them out and wash them, dry them in the air and store them in a desiccator for later use.

[0047] (2) Configure the electrolyte: the electrolyte is composed of 0.55 wt% NH 4 F, 30 wt% H 2 O and ethylene glycol (the remainder) are mixed.

[0048] (3) Using the electrochemical anodizing method, the cleaned titanium plate is used as the anode, the platinum plate is used as the cathode, and the distance between the two electrodes is 40 mm, and the titanium plate is anodized under a DC voltage of 40 V for 3 h. After the reaction, the prepared samples were cleaned with deionized water and dried naturally.

[0049] (4) With absolute ethanol as solvent and anhydrous zinc chloride as solute, prepare 0.01 M zinc chloride ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com