Method for continuously producing neopentyl glycol

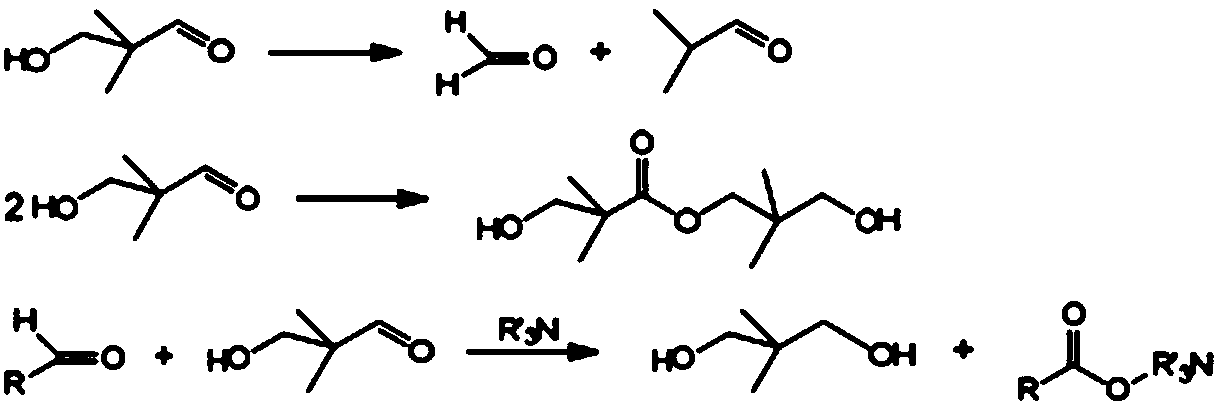

A technology of neopentyl glycol and hydroxypivalaldehyde, applied in chemical instruments and methods, preparation of organic compounds, preparation of aldehyde redox, etc., can solve the problems of strict process conditions, many side reaction products, and adverse effects of HPA continuous process and other problems to achieve the effect of ensuring stable operation, reducing the generation of by-products, improving the conversion rate and product quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

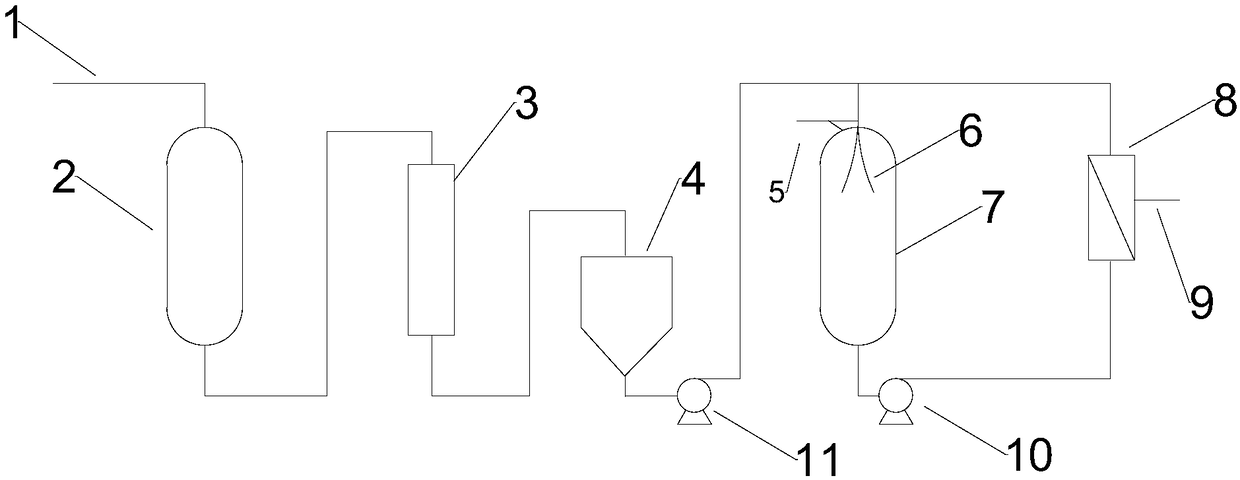

[0027] A method for continuous production of neopentyl glycol, comprising the steps of:

[0028] 1. Mix isobutyraldehyde, formaldehyde and triethylamine in a molar ratio of 1:0.8:0.01, add them into the reactor, and carry out condensation reaction at a temperature of 70°C and a pressure of 80kPa.

[0029] 2. Pass the resulting mixed solution into a tank containing Mg(OH) 2 The catalyst is condensed in a fixed-bed reactor, and the resulting solution containing 80% wtHPNE is passed into a storage tank.

[0030] 3. Use the feed pump to send the HPNE solution into the reflux reactor containing NPG, the catalyst is Raney nickel (the nickel content in the catalyst is 80%wt), and the hydrogenation reaction is carried out at 150 ° C and 6 MPa until the circulating liquid NPG content 98%wt.

[0031] 4. The reaction product is separated by a cross-flow filter, the mass ratio of the circulating liquid and the clear liquid of the filter is controlled at 80, the circulating liquid contai...

Embodiment 2

[0033] A method for continuous production of neopentyl glycol, comprising the steps of:

[0034] 1. Formaldehyde, isobutyraldehyde and triethylamine are mixed and added into the reactor at a molar ratio of 1:1:0.03, and the condensation reaction is carried out at a temperature of 50°C and a pressure of 60kPa.

[0035] 2. Pass the resulting mixed solution into a Ca(OH) 2 The catalyst is condensed in a fixed-bed reactor, and the resulting solution containing 75% wtHPNE is passed into a storage tank.

[0036] 3. Use the feed pump to send the HPNE solution into the reflux reactor containing NPG, the catalyst is Raney nickel (the nickel content in the catalyst is 75%wt), and the hydrogenation reaction is carried out at 180 ° C and 10 MPa until the circulating liquid NPG content 95%wt.

[0037]4. The reaction product is separated by a cross-flow filter, the mass ratio of the circulating liquid and the clear liquid of the filter is controlled at 90, the circulating liquid containin...

Embodiment 3

[0039] A method for continuous production of neopentyl glycol, comprising the steps of:

[0040] 1. Formaldehyde, isobutyraldehyde and triethylamine are mixed into the reactor at a molar ratio of 1:0.9:0.02, and the condensation reaction is carried out at a temperature of 70°C and a pressure of 90kPa.

[0041] 2. Pass the resulting mixed solution into a tank containing Mg(OH) 2 The catalyst is condensed in a fixed-bed reactor, and the resulting solution containing 73% wtHPNE is passed into a storage tank.

[0042] 3. Use the feed pump to send the HPNE solution into the reflux reactor containing NPG, the catalyst is Raney nickel (the nickel content in the catalyst is 90%wt), and the hydrogenation reaction is carried out at 160 ° C and 7 MPa until the circulating liquid NPG content 93%wt.

[0043] 4. The reaction product is separated by a cross-flow filter, the mass ratio of the circulating liquid and the clear liquid of the filter is controlled at 50, the circulating liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com