Bacterial strain for producing bacterial cellulose and isolation and screening method thereof

A bacterial cellulose and screening method technology, applied in the field of microorganisms, can solve the problems of low fermentation yield and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

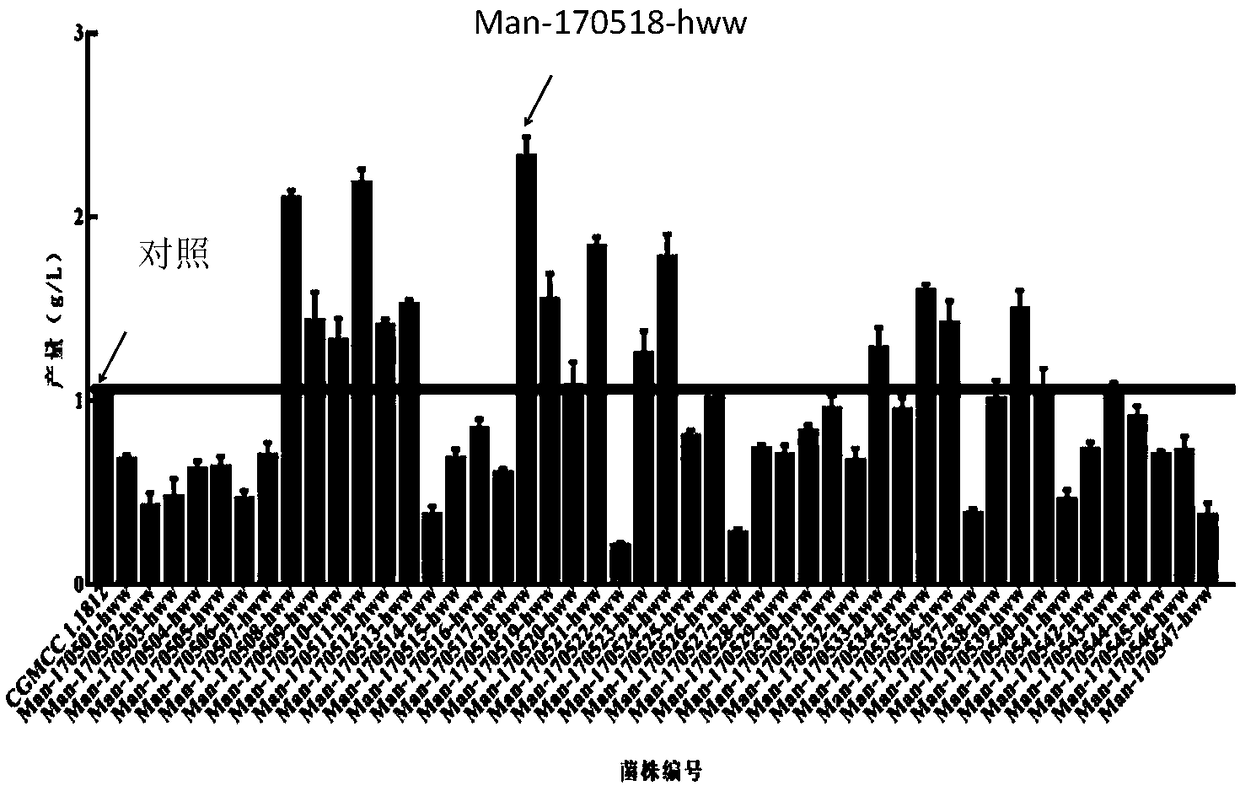

[0052] Embodiment 1: a screening of high-yield bacterial cellulose

[0053] Take about 1g of the rotten part of the fruit, put it into a 18mm×180mm test tube filled with 10mL primary enrichment medium after sterilization, and culture it statically at 30°C for 5 days. There will be a milky white colloidal film on the liquid surface in the tube and the film will not be broken. are positive. Take the film and wash it with 0.9% sterile saline for 3 times, cut it into pieces and place it in a 18mm×180mm test tube filled with 10mL enrichment medium for shaking for 1h, take the shaking solution and spread it on a HS fluorescence screening plate for 5d after gradient dilution Finally, under the irradiation of a 365nm ultraviolet lamp, the plate was irradiated by a 365nm ultraviolet lamp, and a large single colony with obvious fluorescence was picked and cultured in a small test tube containing 2mL of a secondary enrichment medium with a pH value of 7 for 5 days, and the pH of the cult...

Embodiment 2

[0054] Embodiment 2: a screening of high-yield bacterial cellulose (screening pH control example)

[0055] Take about 1g of the rotten part of the fruit, put it into a 18mm×180mm test tube filled with 10mL primary enrichment medium after sterilization, and culture it statically at 30°C for 5 days. There will be a milky white colloidal film on the liquid surface in the tube and the film will not be broken. are positive. Take the film and wash it with 0.9% sterile saline for 3 times, cut it into pieces and place it in a 18mm×180mm test tube filled with 10mL enrichment medium for shaking for 1h, take the shaking solution and spread it on a HS fluorescence screening plate for 5d after gradient dilution Finally, under the irradiation of a 365nm ultraviolet lamp, the plate was irradiated by a 365nm ultraviolet lamp, and a large single colony with obvious fluorescence was picked and cultured in a small test tube containing 2 mL of a secondary enrichment medium with a pH value of 5 fo...

Embodiment 4

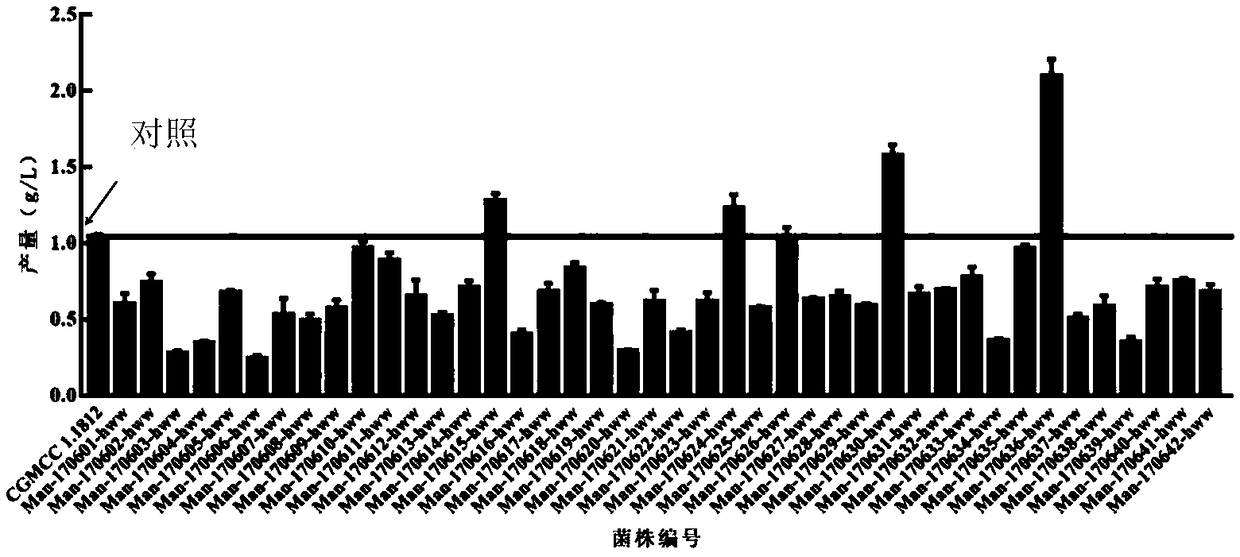

[0065] Embodiment 4: the fermentation of the primary screening bacterial strain of embodiment 2

[0066] The bacterial cellulose-producing control strain (Gluconacetobacter xylinus CGMCC1.1812) preserved on the slope and the 42 cellulose-producing bacterial strains in Example 2 were taken out for activation, and other operations were the same as in Example 3. Compared with the yield of the obtained 42 strains and the control strain Gluconacetobacter xylinus CGMCC 1.1812, only 4 strains exceeded the control strain, and the ratio was 9.5%. ( image 3 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com