Shii-take rice crust and manufacture method thereof

A production method and technology of shiitake mushrooms, which are applied in food ingredients as fluffy agents, functions of food ingredients, food science, etc., can solve the problems affecting the nutritional value of shiitake mushrooms and limiting the functional nutrition of shiitake mushrooms, so as to achieve rich nutrition and nutritional health care value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment relates to the production of a mushroom crispy rice.

[0028] The shiitake mushroom cracker comprises the following raw material components in parts by mass:

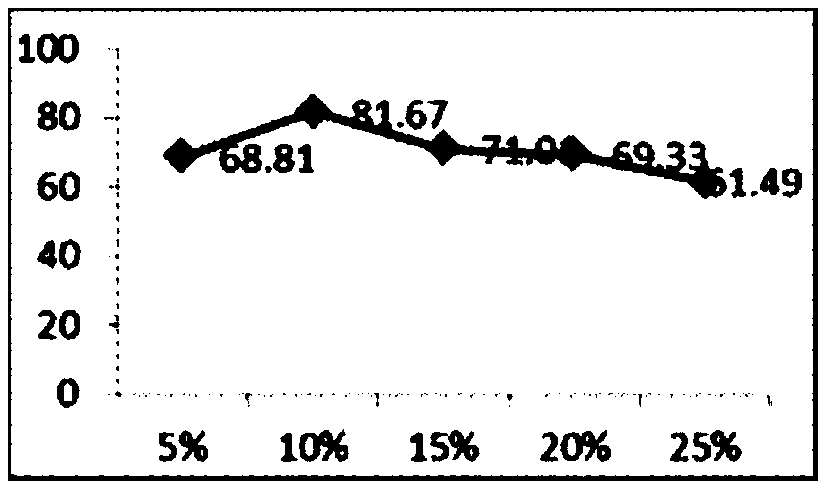

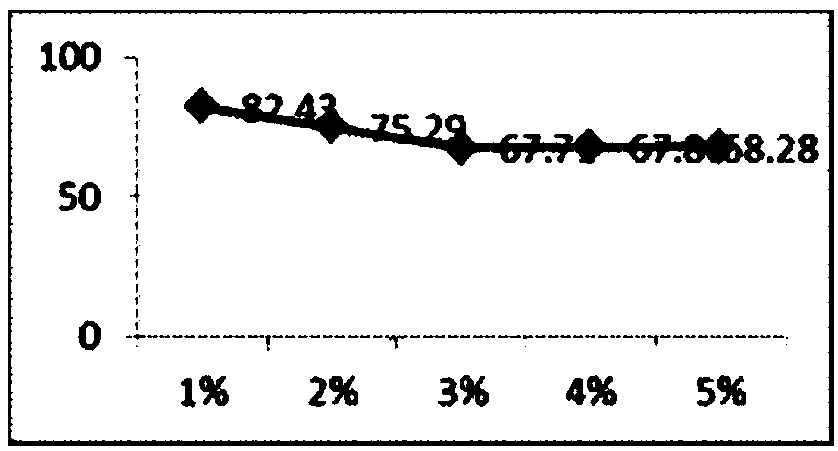

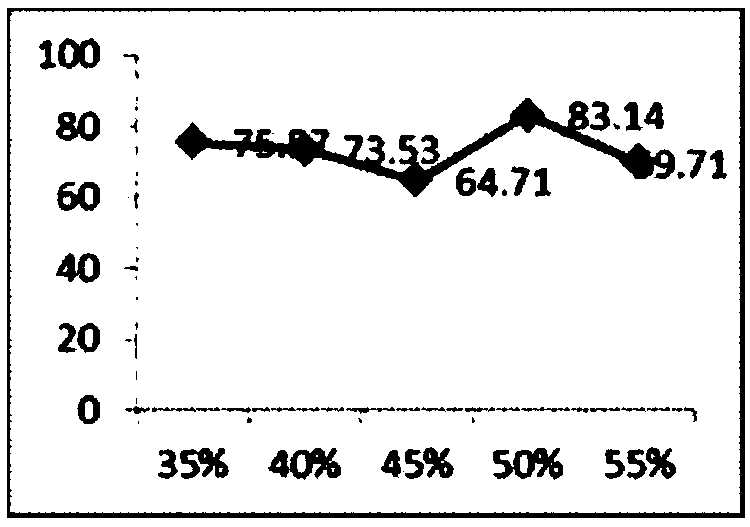

[0029] 5-25 parts of dried shiitake mushrooms, 100 parts of rice, 5-25 parts of corn flour, 35-55 parts of buckwheat flour, 35-55 parts of oat flour, and 0.5-5 parts of leavening agent.

Embodiment 11

[0031] The production of shiitake mushroom crispy rice includes the following steps:

[0032] a. Pretreatment of shiitake mushrooms: take dried shiitake mushrooms or directly take dried shiitake mushrooms, crush them in a grinder, sieve them through a 120-mesh sieve, filter out the residue, and then put the obtained finer shiitake mushroom powder with no particles on the surface in a microwave oven within 400W of microwave conditions for 120s;

[0033] b. Rice pretreatment: take the rice, wash it and soak it in water for 40 minutes to make the moisture content of the rice reach 30%, and then roll the soaked rice into small particles with uniform particle size. The particle size should be moderate and not too broken;

[0034] c. Making crispy rice: fully mix the pretreated rice, shiitake mushroom powder and other raw materials in proportion, and stir evenly; spread plastic wrap on the wooden chopping board, apply a little edible oil, knead the mixed materials and put them on th...

Embodiment 12

[0036] The production of shiitake mushroom crispy rice includes the following steps:

[0037] a. Mushroom pretreatment: take the dried shiitake mushrooms or directly take the dried shiitake mushrooms, crush them in a grinder, sieve them through a 100-mesh sieve, filter out the residue, and then put the obtained finer shiitake mushroom powder with no particles on the surface in a microwave oven within 600W of microwave conditions for 90s;

[0038] b. Rice pretreatment: take the rice, wash it and soak it in water for 1 hour, so that the water content of the rice reaches 35%, and then roll the soaked rice into small particles with uniform particle size. The particle size should be moderate and not too broken;

[0039] c. Making crispy rice: Mix the pretreated rice, shiitake mushroom powder and other raw materials in proportion and stir well; spread plastic wrap on the wooden chopping board, apply a little edible oil, knead the mixed materials and put them on the chopping board P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com