Method for preparing high-activity copper zirconium catalyst by utilizing zirconium oxide ball milling chips

A technology of copper-zirconium catalyst and zirconia ball, which is applied in the field of waste treatment, can solve the problems of large product ratio fluctuation, poor catalytic activity, and small specific surface area, and achieve the effects of strong catalytic activity, stable composition, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

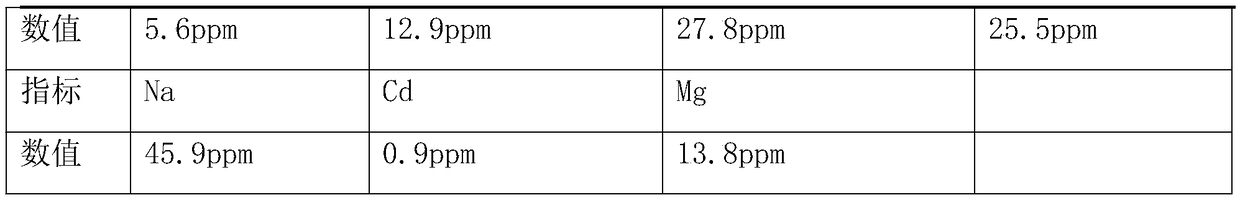

Embodiment 1

[0034] A method for preparing highly active copper-zirconium catalysts by utilizing zirconia ball grinding debris, comprising the following steps:

[0035] (1) adding sodium hydroxide to the grinding debris of zirconia for roasting, the roasting temperature is 385° C., and the roasting time is 2.5 hours, then take it out, add hot pure water to wash, and obtain sodium zirconate solution through filtration;

[0036] (2) The sodium zirconate obtained in step (1) is fed into carbon dioxide until the pH of the solution is 7.85, filtered and washed, then added with copper acetate solution for slurrying, and the slurryed material is spray-dried to obtain a dry powder;

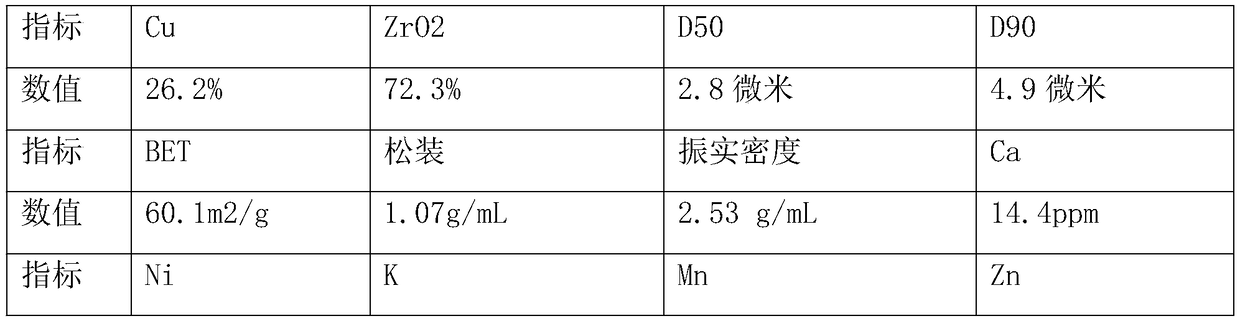

[0037] (3) Put the dry powder obtained in step (2) into a hydrogen reduction furnace for reduction, the reduction temperature is 458°C, and the reduction time is 1.95 hours, then airflow crushing is carried out under the protection of nitrogen, and after screening and vacuum packaging, A copper-zirconium catalyst is o...

Embodiment 2

[0048] A method for preparing highly active copper-zirconium catalysts by utilizing zirconia ball grinding debris, comprising the following steps:

[0049] (1) adding sodium hydroxide to the grinding debris of zirconia for roasting, the roasting temperature is 395° C., and the roasting time is 2.8 hours, then take it out, add hot pure water for washing, and obtain sodium zirconate solution through filtration;

[0050] (2) The sodium zirconate obtained in step (1) is fed into carbon dioxide until the pH of the solution is 7.85, filtered and washed, then added with copper acetate solution for slurrying, and the slurryed material is spray-dried to obtain a dry powder;

[0051] (3) Put the dry powder obtained in step (2) into a hydrogen reduction furnace for reduction, the reduction temperature is 475°C, and the reduction time is 2.1 hours, then airflow crushing is carried out under the protection of nitrogen, and after screening and vacuum packaging, A copper-zirconium catalyst i...

Embodiment 3

[0062] A method for preparing highly active copper-zirconium catalysts by utilizing zirconia ball grinding debris, comprising the following steps:

[0063] (1) adding sodium hydroxide to the grinding debris of zirconia for roasting, the roasting temperature is 385° C., and the roasting time is 2.7 hours, then take it out, add hot pure water for washing, and obtain sodium zirconate solution through filtration;

[0064] (2) The sodium zirconate obtained in step (1) is fed into carbon dioxide until the pH of the solution is 7.9, washed after filtration, then added with copper acetate solution for slurrying, and the slurryed material is spray-dried to obtain a dry powder;

[0065] (3) Put the dry powder obtained in step (2) into a hydrogen reduction furnace for reduction, the reduction temperature is 435° C., and the reduction time is 2.3 hours, then air crushing is carried out under the protection of nitrogen, and after screening and vacuum packaging, A copper-zirconium catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com