A kind of inhibitor for inhibiting sulfurized m in flotation process and using method thereof

A flotation process and inhibitor technology, applied in flotation, solid separation, etc., to achieve the effect of simple preparation method, strong inhibition ability, and promotion of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

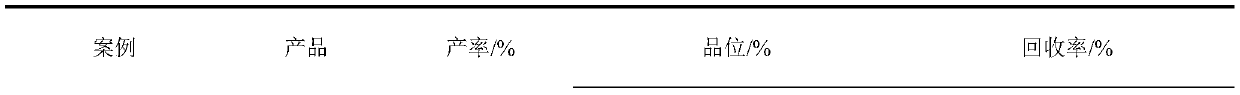

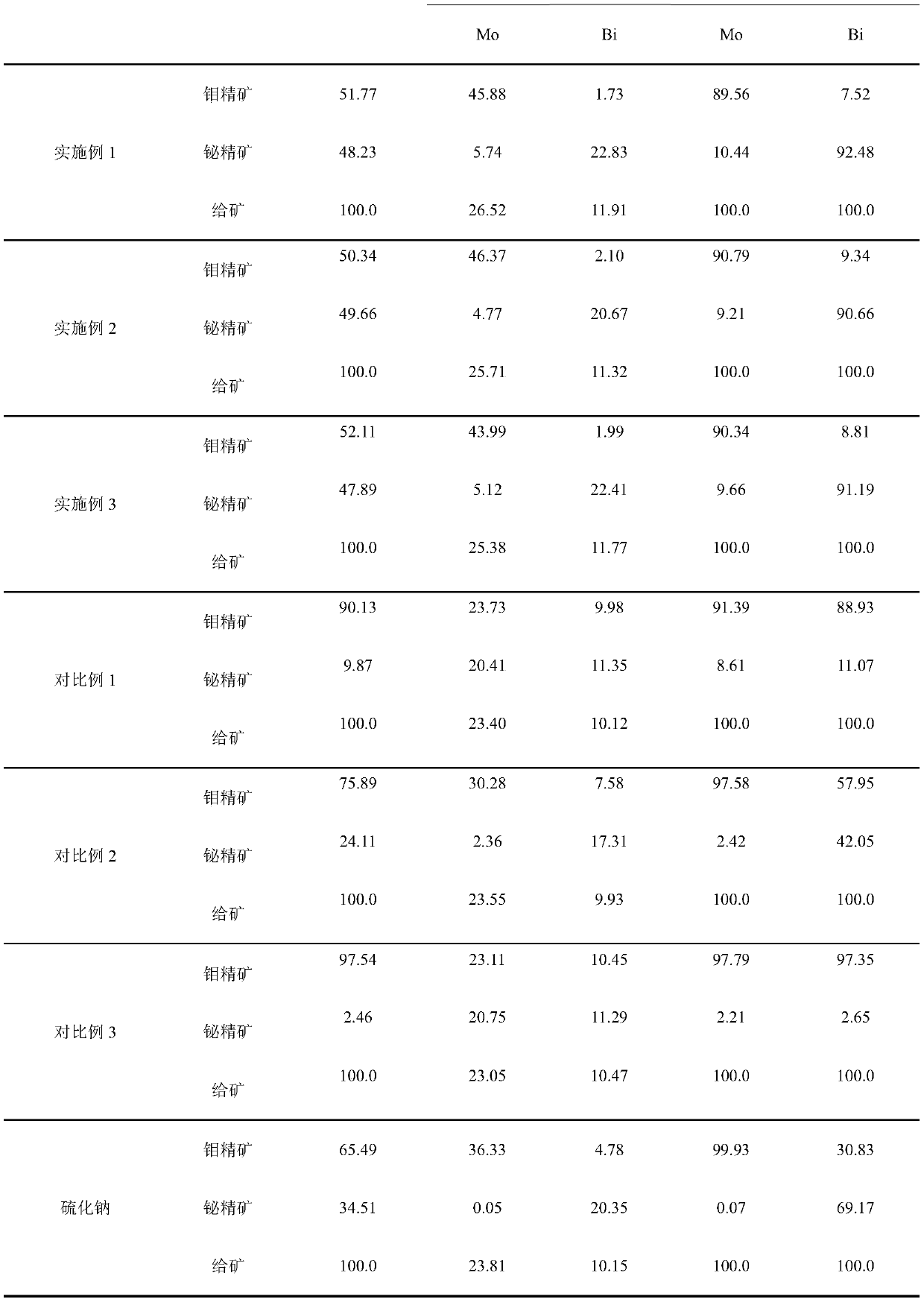

Examples

Embodiment 1

[0034] ⑴In parts by weight, add a certain amount of ultrapure water into a three-necked flask equipped with a stirring and condensing reflux device. As for the constant temperature water bath, add 15 parts of gallic acid after passing nitrogen for 30 minutes, and stir until fully dissolved;

[0035] (2) Add 1.5 parts of sodium bisulfite to the result of step (1), heat in a water bath to 85°C, and react for 6 hours;

[0036] (3) Add 3 parts of formaldehyde solution to the reactant obtained in step (2), stir for 2 minutes, then add 3 parts of ethanolamine, react at 40°C for 5 hours, and the obtained liquid is the inhibitor.

Embodiment 2

[0038] ⑴In parts by weight, add a certain amount of ultrapure water into a three-necked flask equipped with a stirring and condensing reflux device. As for the constant temperature water bath, after passing nitrogen for 30 minutes, add 10 parts of tannic acid, and stir until fully dissolved;

[0039] (2) Add 1 part of sodium bisulfite to the result of step (1), heat in a water bath to 85°C, and react for 6 hours;

[0040] (3) Add 2 parts of formaldehyde solution to the reactant obtained in step (2), stir for 2 minutes, then add 2 parts of dimethylamine, react at 40°C for 5 hours, and the obtained liquid is the inhibitor.

Embodiment 3

[0042] ⑴In parts by weight, add a certain amount of ultrapure water into a three-necked flask equipped with a stirring and condensing reflux device, and in a constant temperature water bath, add 12.5 parts of tannin extract after 30 minutes of nitrogen gas, and stir until fully dissolved;

[0043] (2) Add 1.2 parts of potassium bisulfite to the result of step (1), heat in a water bath to 85°C, and react for 6 hours;

[0044] (3) Add 2.5 parts of formaldehyde solution to the reactant obtained in step (2), stir for 2 minutes, then add 2.5 parts of dimethylamine, react at 40°C for 5 hours, and the obtained liquid is the inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com