Heat-dissipation magnetic plastic and preparation method thereof

A heat dissipation and magnetic technology, applied in the direction of coating, etc., can solve the problems of affecting the mechanical properties of magnetic plastics, weak interfacial bonding, and affecting the strength of products, so as to improve processing flow performance, increase mold filling rate, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

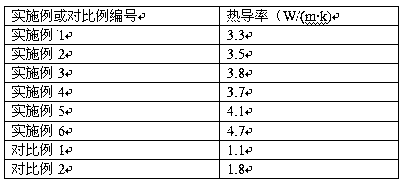

Examples

Embodiment 1

[0038] Adopt the following method to prepare the heat dissipation magnetic plastic of the present invention:

[0039] a. Preparation of magnetic liquid: mix ferric chloride and ferric chloride in a molar ratio of 1:0.9, dissolve in water, then add polyethylene glycol, and under nitrogen protection, add concentrated ammonia water dropwise until the pH is 8.5, Stir and react in a water bath at 50°C for 60 minutes, the stirring speed is 1000rpm, then cool down to room temperature, and separate the solid and liquid. The solid is nano-ferrite magnetic particles coated with polyethylene glycol, which is dispersed in the oily base liquid to obtain a magnetic liquid. The addition of polyethylene glycol is 10% of ferric chloride weight; The oily base liquid is liquid epoxy resin; The ratio is 1g: 1mL;

[0040] b. Preparation of material A: Add nylon, antistatic agent conductive carbon black and stearate stabilizer to the magnetic liquid, stir at 1000rpm for 40min, and obtain material ...

Embodiment 2

[0044] Adopt the following method to prepare the heat dissipation magnetic plastic of the present invention:

[0045] a. Preparation of magnetic liquid: mix ferric chloride and ferric chloride in a molar ratio of 1:1.1, dissolve in water, then add polyethylene glycol, and under nitrogen protection, add concentrated ammonia water dropwise until the pH is 9.5, Stir and react in a water bath at 70°C for 30 minutes, the stirring speed is 1500rpm, then cool down to room temperature, and separate the solid and liquid. The solid is nano-ferrite magnetic particles coated with polyethylene glycol, which are dispersed in the oily base liquid to obtain a magnetic liquid. The addition of Polyethylene Glycol is 30% of ferric chloride weight; Described oily base liquid is liquid silicone resin; The ratio is 1g: 4mL;

[0046] b. Preparation of material A: Add nylon, antistatic agent conductive carbon black and stearate stabilizer to the magnetic liquid, stir at 1500rpm for 20min, and obtain...

Embodiment 3

[0050] Adopt the following method to prepare the heat dissipation magnetic plastic of the present invention:

[0051] a. Preparation of magnetic liquid: mix ferric chloride and ferric chloride in a molar ratio of 1:1, dissolve in water, then add polyethylene glycol, and under nitrogen protection, add concentrated ammonia water dropwise until the pH is 9, Stir and react in a water bath at 60°C for 40 minutes, with a stirring speed of 1200rpm, then cool down to room temperature, and separate the solid and liquid. The solid is nano-ferrite magnetic particles coated with polyethylene glycol, which are dispersed in the oily base liquid to obtain a magnetic liquid. The addition of polyethylene glycol is 15% of ferric chloride weight; The oily base liquid is liquid epoxy resin; The ratio is 1g: 2mL;

[0052] b. Preparation of material A: Add nylon, antistatic agent conductive carbon black and stearate stabilizer to the magnetic liquid, stir at 1200rpm for 30min, and obtain material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com