Steel wire mesh frame gel glass bead building partition wall thermal insulation system and installation method thereof

A technology of gel glass beads and steel wire grid, which is applied in the field of building wall systems, can solve the problems of high temperature resistance and poor fire resistance, achieve excellent heat preservation, simple installation process, and improve crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

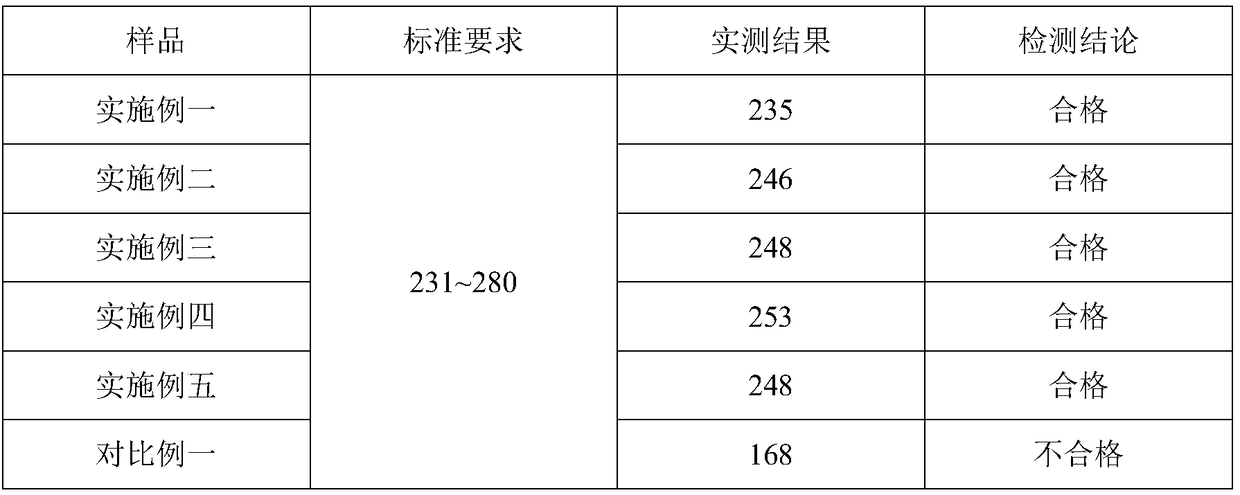

Embodiment 1

[0037] A preparation method of a gel glass bead insulation board, comprising the steps of:

[0038] (1) Preparation of modified powder curing agent: a, 20 parts of powder curing agent, 50 parts of high-strength Portland cement, 1 part of active silica gel binder, 2 parts of nano-airgel, and 0.2 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material to form a modified powder curing agent;

[0039] (2) Material preparation: 100 parts of expanded perlite, 10 parts of inorganic silicon gel, 5 parts of cement-based binder, 20 parts of modified powder curing agent, 15 parts of nano-airgel and 5 parts of anti-seepage bonding material ;

[0040](3) A low-carbon cold-drawn steel wire welded mesh is built in the mold, and then the mixture of step (2) is poured into the mold for compression molding, and the thickness of the insulation board is 100mm.

Embodiment 2

[0042] A preparation method of a gel glass bead insulation board, comprising the steps of:

[0043] (1) Preparation of modified powder curing agent: a. 20 parts of powder curing agent, 50 parts of high-strength Portland cement, 1.2 parts of active silica gel binder, 2.2 parts of nano-airgel, and 0.3 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material to form a modified powder curing agent;

[0044] (2) Materials: 105 parts of expanded perlite, 12 parts of inorganic silica gel, 5 parts of cement-based binder, 22 parts of modified powder curing agent, 15 parts of nano-airgel and 6 parts of anti-seepage bonding material ;

[0045] (3) A low-carbon cold-drawn steel wire welded mesh is built in the mold, and then the mixture of step (2) is poured into the mold for compression molding, and the thickness of the insulation board is 100mm.

Embodiment 3

[0047] A preparation method of a gel glass bead insulation board, comprising the steps of:

[0048] (1) Preparation of modified powder curing agent: a, 22 parts of powder curing agent, 52 parts of high-strength Portland cement, 1 part of active silica gel binder, 2.2 parts of nano-airgel, and 0.4 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material to form a modified powder curing agent;

[0049] (2) Material preparation: 110 parts of expanded perlite, 15 parts of inorganic silicon gel, 8 parts of cement-based binder, 23 parts of modified powder curing agent, 20 parts of nano-airgel and 6 parts of anti-seepage bonding material ;

[0050] (3) A low-carbon cold-drawn steel wire welded mesh is built in the mold, and then the mixture of step (2) is poured into the mold for compression molding, and the thickness of the insulation board is 100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com