Aquaculture system of biomass cogeneration

A technology of combined heat and power generation and aquaculture, which is applied in the field of breeding and comprehensive utilization of resources, and can solve the problems of lack of comprehensive treatment, limited breeding sites, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

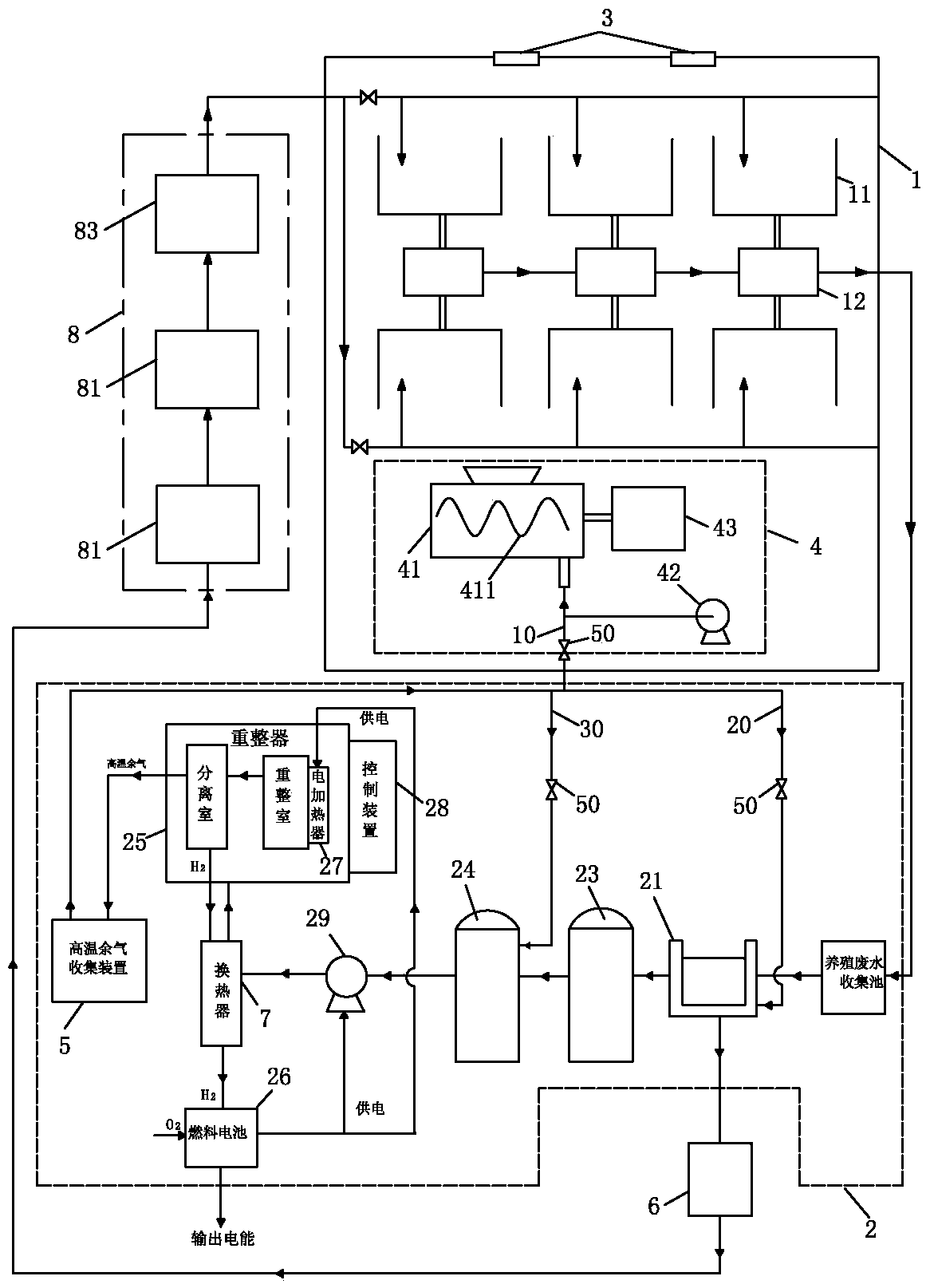

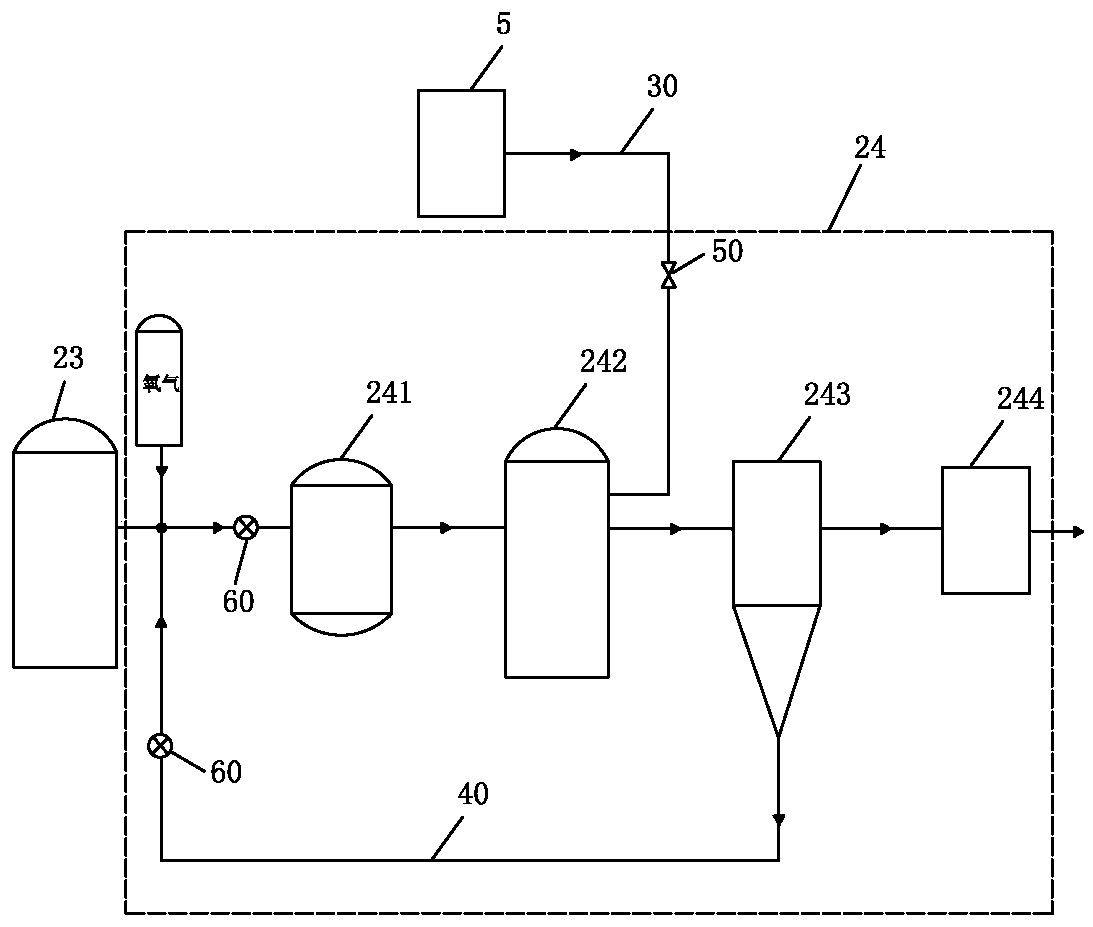

[0032] Aquaculture systems for biomass combined heat and power, such as figure 1As shown, it includes an indoor aquaculture room 1, an aquaculture wastewater thermal power station 2 arranged around the indoor aquaculture room 1, a biogas slurry and residue treatment device 6, an organic fertilizer manufacturing device 7, and an aquaculture water recovery treatment device 8. The indoor aquaculture room 1 is set There are lighting device 3, temperature regulator 4 and several groups of cultivation units, each group of cultivation units includes two cultivation ponds 11 and a drainage pond 12 arranged between the two cultivation ponds 11, the water inlet of drainage pond 12 is connected to the two cultivation ponds. The water outlet of pool 11 is communicated by pipeline. The aquaculture wastewater thermal power station 2 includes a control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com