Organosilicone prepolymer and organosilicone-acrylic resin prepared therefrom

A technology of acrylic resin and organosilicon, which is applied in the direction of silicon organic compounds, etc., can solve the problems of difficult to reflect the hydrophobicity of organosilicon materials, restrict movement, enrichment, etc., and achieve convenient production, good adhesion, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] 1. Preparation of silicone prepolymer

[0061] S100: Mix 100ml of toluene and 150ml of water into a 500ml flask, then take 80g of trimethylchlorosilane and 20g of methyldichlorosilane into the dropping funnel, keep the temperature below 25°C, stir, and add the mixture dropwise body. After the dropwise addition, pour the toluene aqueous solution into a separatory funnel, let stand, separate layers, remove the water layer, and then wash with water three times. Then add 30g of concentrated sulfuric acid, catalytic reforming at 35°C for 6 hours, then pour the mixture into a separatory funnel, let stand, separate layers, and remove the acidic water layer. Add about 0.5% mass fraction of activated carbon, stir, heat, after 30 minutes, let stand, separate layers, and remove the activated carbon. Neutralize with water and wash it until the solution is neutral, and then carry out vacuum distillation with an oil pump to collect colorless organosilicon prepolymer I.

[0062] fr...

Embodiment 1

[0067] Add water, SDS / OP-10 / Span20 and some n=3 organosilicon prepolymers and methyl methacrylate into a 250ml four-neck flask equipped with a thermometer, stirring device, dropping funnel and condenser. Stir and pre-emulsify at temperature (50°C) for 30 minutes. Then the temperature was raised to 80°C, and at the same time, the prepared initiator solution and the remaining mixed monomers were added dropwise. After the dropwise addition, keep the temperature for 3 hours, lower the temperature to 55° C., adjust the pH to 7 with ammonia water, and cool and discharge.

Embodiment 2

[0069] Add water, SDS / OP-10 / Span20 and some n=7 organosilicon prepolymers and methyl methacrylate into a 250ml four-neck flask equipped with a thermometer, a stirring device, a dropping funnel and a condenser. Stir and pre-emulsify at ℃ for 30min. Then the temperature was raised to 80°C, and at the same time, the prepared initiator solution and the remaining mixed monomers were added dropwise. After the dropwise addition, keep the temperature for 3 hours, lower the temperature to 55° C., adjust the pH to 7 with ammonia water, and cool and discharge.

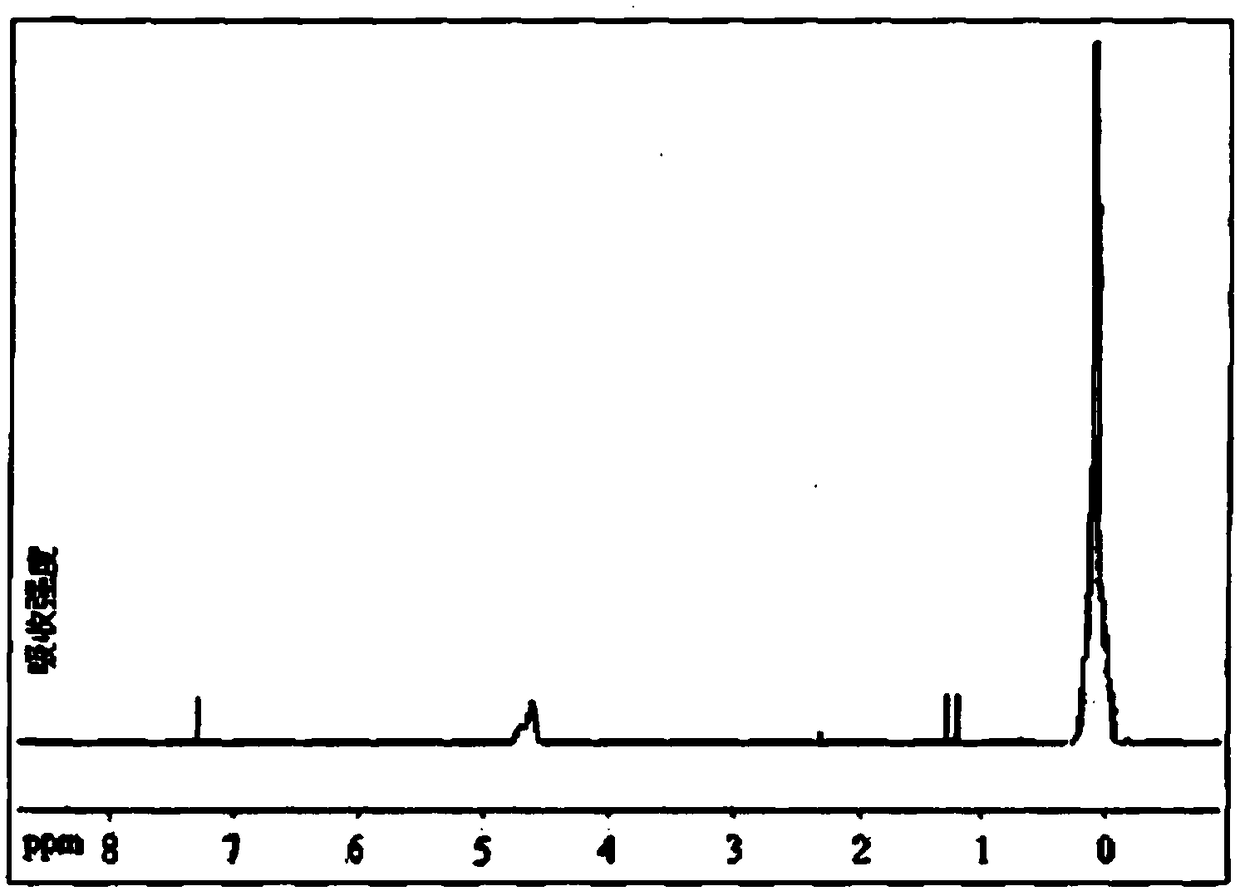

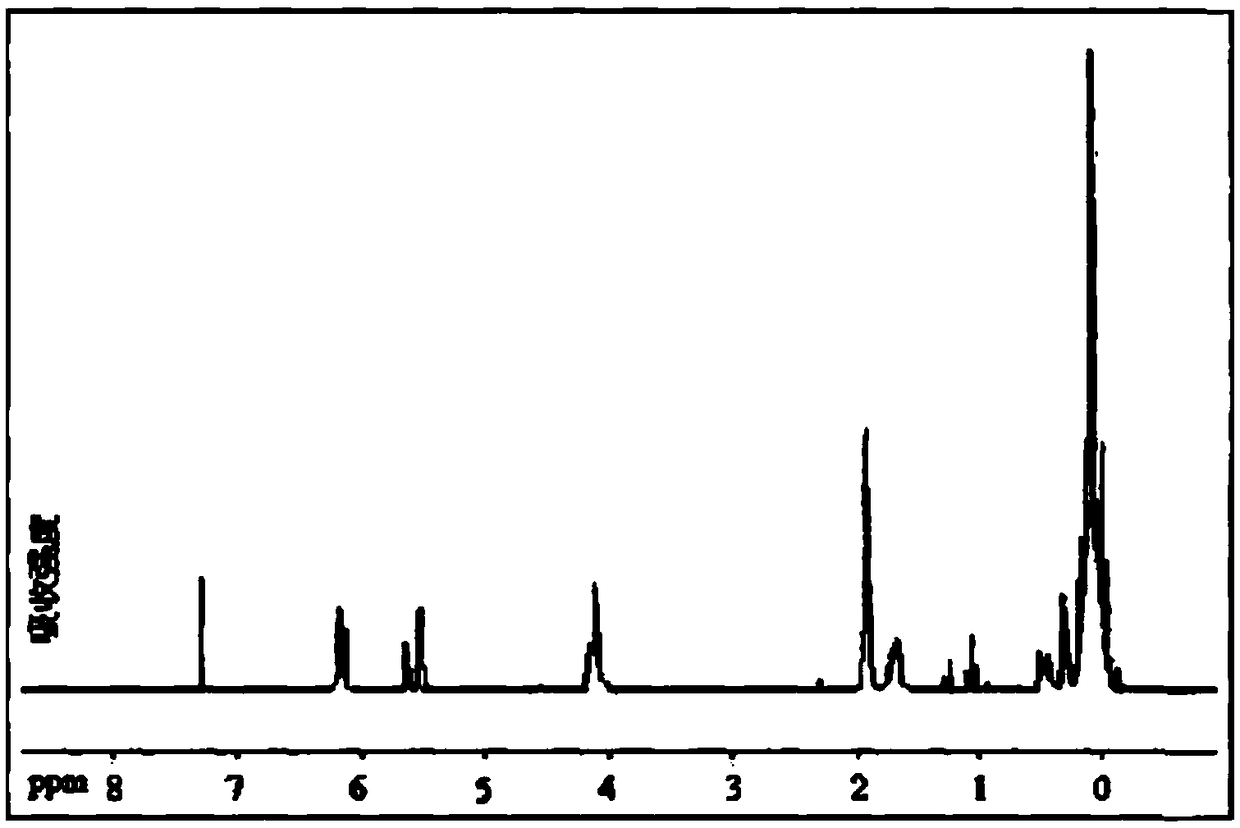

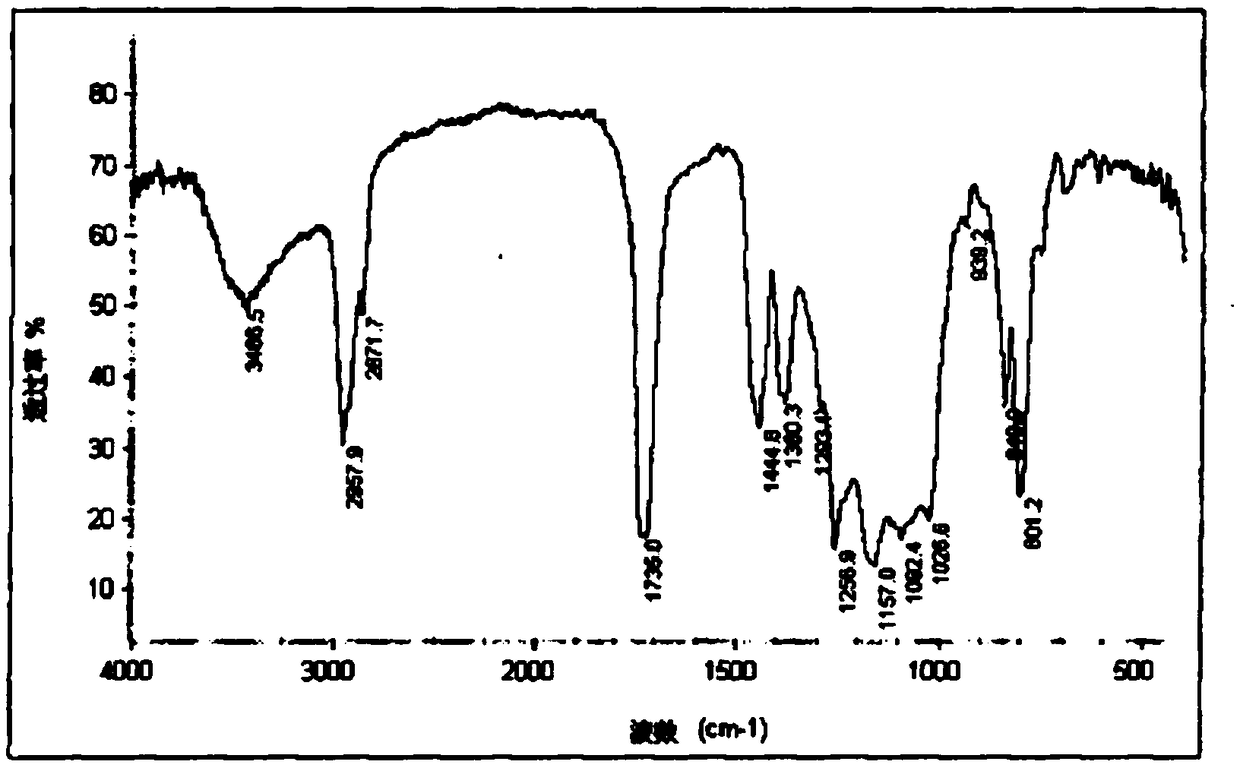

[0070] After the reaction product was purified by distillation under reduced pressure, its structure was identified by infrared spectrum IR, and the desired result was the same as image 3 Consistent with that shown. from image 3 We can see that: 2960.4cm-1 is -CH 3 The upper C-H stretching vibration, 2903.6cm-1 is the C-H stretching vibration of -CH2-, 1258.2cm-1 is the bending vibration of Si-(CH3), 799.4cm-1 is the bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com