Method for using HS-GC (headspace gas chromatography) external standard method to measure residual acrylic acid in acrylic polymer

An acrylic acid polymer and acrylic acid technology, applied in the field of analytical chemistry, can solve problems such as human and environmental hazards, impact of test results, and inability to quantitatively test, achieving good repeatability, high accuracy, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

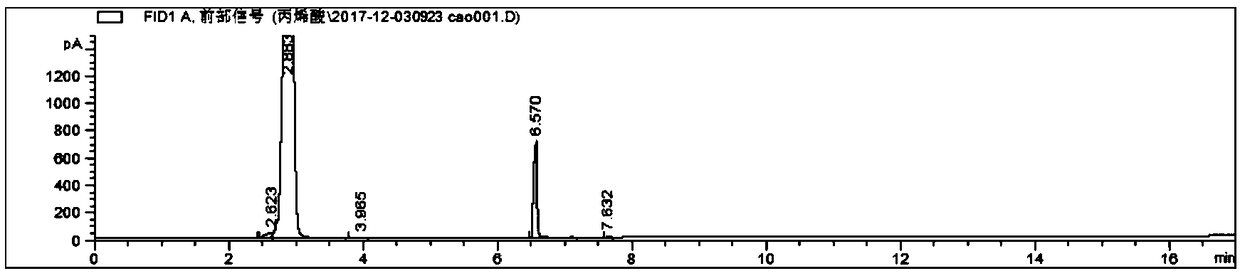

Examples

Embodiment 1

[0040] 1. Instrument Preparation

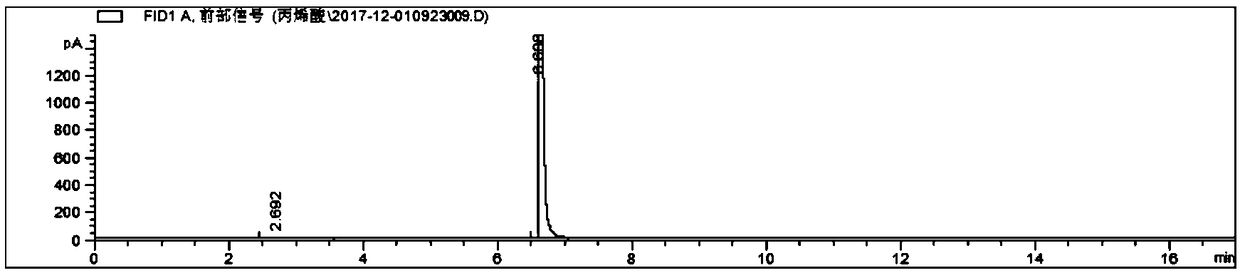

[0041] Adopt Agilent 7890B gas chromatograph, 7697A headspace sampler for headspace injection, equilibrate at 60°C for 15min; the chromatographic column is DB-WAX (or a chromatographic column with equivalent polarity), the column length is 30m, and the inner diameter of the column is 320μm. The initial column temperature is 130°C, keep it for 2min, then raise the temperature to 190°C at a rate of 20°C / min, keep it for 12min, the carrier gas flow rate is 1ml / min; 4:1, injection volume 1μl; hydrogen flame detector, the detection temperature is 260°C, the hydrogen flow rate is 40ml / min, and the air flow rate is 300ml / min.

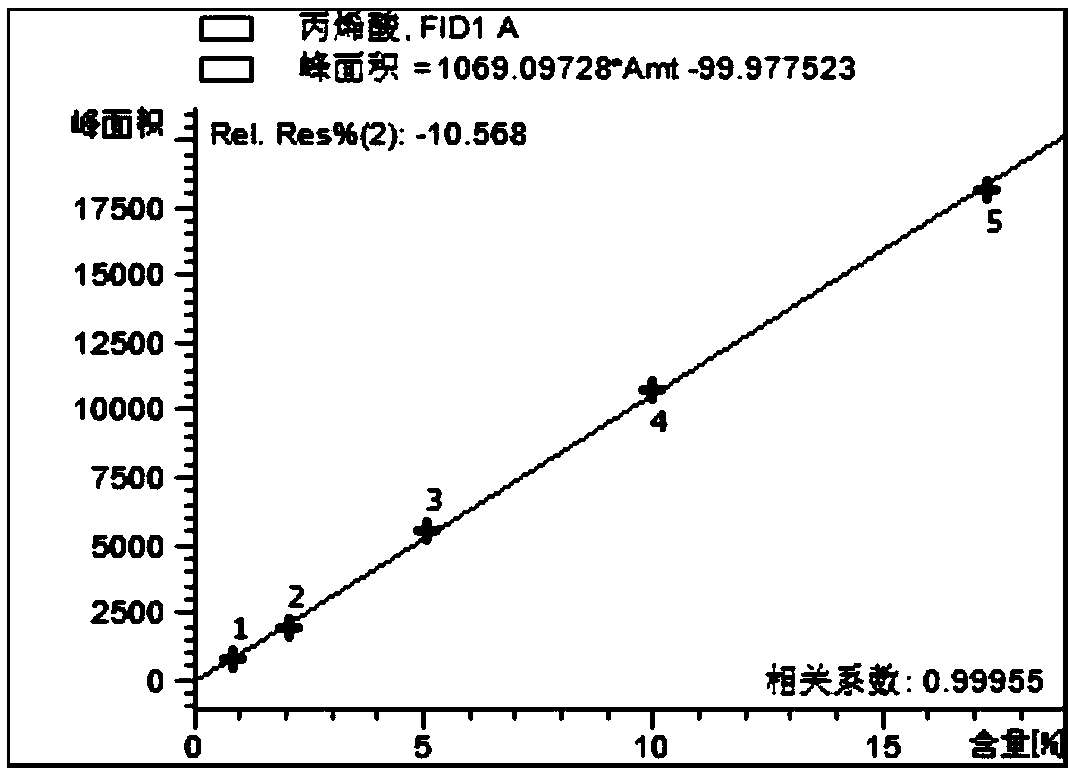

[0042] 2. Drawing of standard curve

[0043]Preparation of acrylic acid standard solution: Accurately weigh 50.0mg of acrylic acid standard in a beaker, dilute with distilled water, transfer to a 500ml volumetric flask, dilute to the mark with distilled water, and prepare 100mg / L stock solution VI; accurately pipette 10.00ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com