Method and device for achieving ultra-low emission of sulfur dioxides and nitrogen oxides from flue gas by two-stage ozone oxidation synergistic absorption

A nitrogen oxide and ozone oxidation technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of large flue gas temperature fluctuations, large floor space, difficulties, etc., to avoid excessive dosing, high efficiency Absorption and removal, the effect of low pharmaceutical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

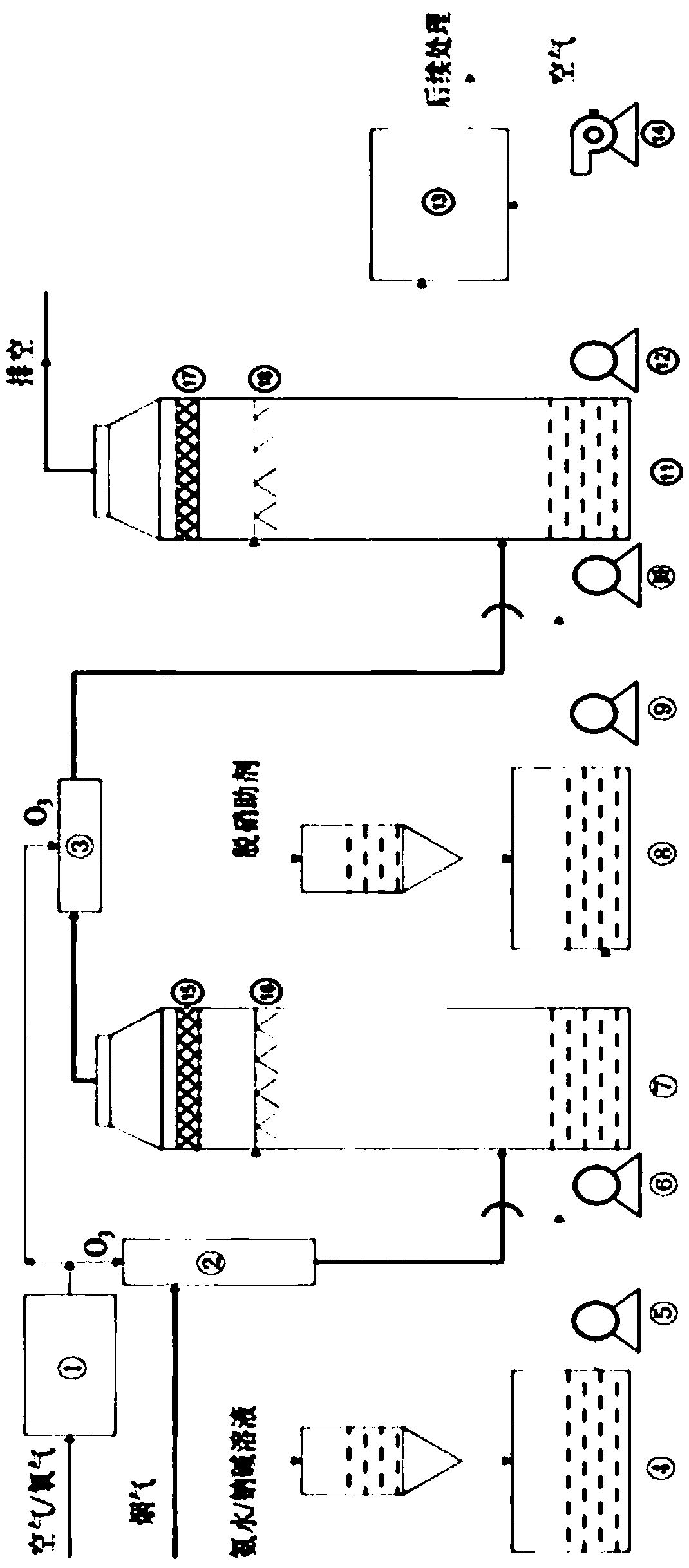

[0028] The present invention firstly provides a device for realizing ultra-low emission of sulfur dioxide and nitrogen oxides in flue gas by synergistic absorption of two-stage ozone oxidation, such as figure 1 As shown, the device includes a primary oxidizer, a primary absorption tower, a secondary oxidizer and a secondary absorption tower, which are sequentially arranged in the flue of the flue gas to be treated, and finally discharge the purified flue gas into the atmosphere. The primary oxidizer ② is placed in the flue before the primary absorption tower ⑦, and the secondary oxidizer ③ is placed in the primary absorption tower ⑦ and the secondary absorption tower flue between. The bottom gas inlet of the primary absorption tower ⑦ is connected to the outlet of the primary oxidizer ②, and the upper gas outlet is connected to the secondary oxidizer ③. Secondary absorption tower The bottom gas inlet is connected to the outlet of the secondary oxidizer ③, and the upper gas ...

Embodiment 2

[0031] The layout of the flue gas purification device is as follows: figure 1 As shown, the type of flue gas to be treated is industrial boiler flue gas. After dust removal, the particulate matter, O 2 , SO 2 and NO content (as NO 2 Count) respectively 45mg / m 3 , 8% (volume percentage), 650mg / m 3 and 420mg / m 3 , the flue gas temperature is 130°C, and the flue gas volume is 250,000m 3 / h,O 3 The total dosage is 76kg / h, 10% (volume percentage) of which is put into the primary oxidizer ②, and 90% (volume percentage) is put into the secondary oxidizer ③. After the primary oxidation, the flue gas passes through the spray device of the primary absorption tower⑦ Countercurrent absorption primary absorption tower ⑦ The absorption liquid uses a mixed solution of by-product sodium hydroxide and sodium hypochlorite with a mass concentration of 10%, and the liquid-gas ratio is 2.4L / m 3 , SO 2 Absorption efficiency of 92%, NO x The absorption efficiency is 30%. The denitrificat...

Embodiment 3

[0033] The layout of the flue gas purification device is as follows: figure 1 As shown, the treatment flue gas category is coke oven flue gas, particulate matter in flue gas, O 2 , SO 2 and NO content (as NO 2 Count) respectively 19mg / m 3 , 9% (volume percentage), 450mg / m 3 and 600mg / m 3 , the flue gas temperature is 140°C, and the treated flue gas volume is 540,000m 3 / h,O 3 The total dosage is 260kg / h, 30% (volume percentage) of which is put into the primary oxidizer ②, and 70% (volume percentage) is put into the secondary oxidizer ③. The first-stage absorption tower ⑦ uses ammonia solution with a mass concentration of 6% as the absorption liquid, and the liquid-gas ratio is 2.5L / m 3 , after the primary oxidation, the flue gas passes through the spray device of the primary absorption tower ⑦ After countercurrent absorption, SO 2 The absorption and removal efficiency is 95%, NO x The absorption efficiency is 40%. The urea solution with a mass concentration of 5% f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com