Preparation method of Ruddlesden-Popper-like perovskite type catalytic material

A perovskite-type, catalytic material technology, applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of catalyst deactivation, complex preparation process, selectivity reduction, etc., to achieve energy reduction consumption, preparation method and process are simple, and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

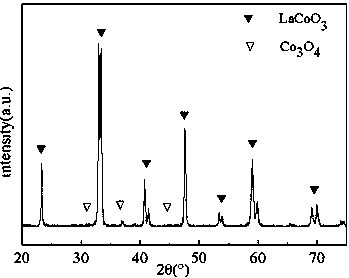

Embodiment 1

[0030] (1) Weigh the perovskite metal precursor, metal oxide precursor and complexing agent respectively, the perovskite metal precursor is composed of rare earth nitrate and transition metal nitrate, and the metal oxide precursor is composed of The nitrate composition of one of the alkaline earth elements, boron group elements or transition metal elements; the nitrate in the rare earth nitrate, transition metal nitrate and metal oxide precursor is according to the molar ratio 1:x:y (0< The ratio of x≤1; 0<y≤1) is dissolved in deionized water in turn, and the total molar concentration of metal ions in the solution is controlled to be 0.5-2.0 mol / L, then a complexing agent is added, and stirred at room temperature for 0.5h to obtain a precursor compound solution; the number of moles of the complexing agent added is 1 to 2 times the sum of the number of moles of all metal ions added. The rare earth nitrate in the perovskite metal precursor is one of lanthanum nitrate, cerium nit...

Embodiment 2

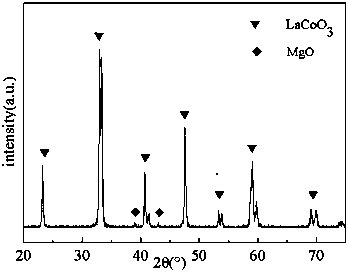

[0041] (1) In this example, the rare earth nitrate and transition metal nitrate in the perovskite metal precursor are selected from La nitrate and Co nitrate respectively, and the metal elements in the metal oxide precursor are selected from alkaline earth elements. Mg, that is, the metal oxide precursor is the nitrate of Mg. Weigh the rare earth nitrate, transition metal nitrate and metal oxide precursor according to the molar ratio La:Co:Mg=1:1:0.2. La(NO 3 ) 3 •6H 2 O 17.67g, Co(NO 3 ) 2 •6H 2 O 11.76g, Mg(NO 3 ) 2 •6H 2 O 2.07g was dissolved in deionized water successively, and the total molar concentration of metal ions in the control solution was 2mol / L, then 18.59g of complexing agent citric acid was added, stirred at room temperature for 0.5h, and the components were mixed uniformly to obtain the precursor The solution is mixed, and the number of moles of citric acid added is 1 times of the sum of the number of moles of all metal ions added.

[0042] (2) Heat ...

Embodiment 3

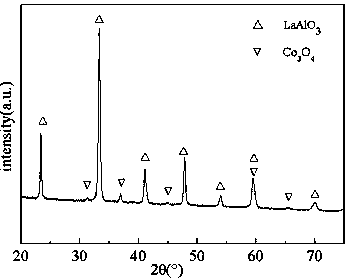

[0049] (1) In this example, the rare earth nitrate and transition metal nitrate in the perovskite metal precursor are selected from La nitrate and Co nitrate respectively, and the metal oxide precursor is selected from Mn in transition metal nitrate Nitrate, the nitrate in the rare earth nitrate, transition metal nitrate and metal oxide precursor according to the molar ratio La:Co:Mn=1:1:0.6, weigh La(NO3) 3 •6H 2 O 17.67 g, Mn(NO3) 2 •6H 2 O 8.59 g, Co(NO3) 2 •6H 2 O 11.76g and be dissolved in deionized water successively, the total molar concentration of metal ions in the control solution is 2mol / L, then add complexing agent ethylenediaminetetraacetic acid 30.55g, stir 0.5h at room temperature, make each composition mix homogeneously, A precursor mixed solution is obtained, and the mole number of ethylenediaminetetraacetic acid is one time of the sum of the mole numbers of all metal ions added.

[0050] (2) Heat the precursor mixed solution obtained in step (1) to 90°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com