Odorless TPE (Thermoplastic Elastomer) material for medical oxygen delivery hose and preparation method thereof

A hose and oxygen delivery technology, applied in the field of odorless medical oxygen delivery hose TPE material and its preparation, can solve the problems of large rubber smell, breeding of bacteria, high processing temperature of TPE material, and achieve good resilience and compression deformation resistance. Soft touch, excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

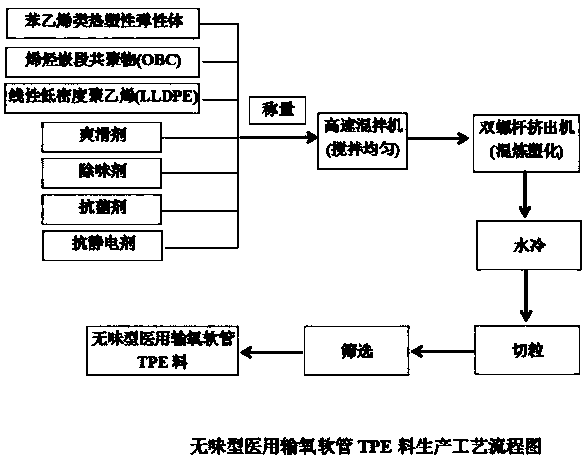

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 Shown, a kind of tasteless type medical oxygen hose TPE material and preparation method thereof, comprise the component of following parts by weight:

[0025] Styrene thermoplastic elastomer 20-50 parts

[0026] Olefin block copolymer (OBC) 30-50 parts

[0027] Linear low density polyethylene (LLDPE) 10-40 parts

[0028] Slippery agent 0.2-0.5 parts

[0029] Deodorant 0.1-0.5 parts

[0030] Antibacterial agent 0.05-0.2 parts

[0031] Antistatic agent 0.1-0.6 parts;

[0032] The styrenic thermoplastic elastomer is styrene-ethylene-butylene-styrene block copolymer (SEBS), styrene-isoprene-styrene block copolymer (SIS), styrene-ethylene- At least one of ethylene-propylene-styrene block copolymers (SEEPS); the olefin block copolymers (OBC) used are segments of crystallizable ethylene-octene with low comonomer content and high melting temperature ( hard segment)...

Embodiment 1

[0035] A kind of tasteless type medical oxygen hose TPE material, comprises the following components by weight:

[0036] SEBS 30 parts

[0037] Olefin block copolymer (OBC) 25 parts

[0038] Linear low density polyethylene (LLDPE) 35 parts

[0039] Oleic acid amide 0.2 parts

[0040] Porous aluminum-silicon-organic mixture particles 0.2 parts

[0041] Polyhexamethylene (bis)arc carbonate 0.1 part

[0042] Antistatic agent 0.5 parts.

[0043] The odorless medical oxygen hose TPE material is prepared through the following steps:

[0044] (1) According to the proportion of each component in the formula, put it into the high mixer after weighing, and stir and mix for 10 minutes to obtain a uniform premix;

[0045] (2) Put the above-mentioned premix into a twin-screw extruder to extrude and granulate, and the extrusion temperature range is 130-170°C; wherein, the temperatures of the first zone to the eighth zone of the twin-screw extruder are respectively: 130°C, 150°C, 160°...

Embodiment 2

[0047] A kind of tasteless type medical oxygen hose TPE material, comprises the following components by weight:

[0048] SIS 25 copies

[0049] Olefin block copolymer (OBC) 40 parts

[0050] Linear low density polyethylene (LLDPE) 25 parts

[0051] Zinc stearate 0.3 parts

[0052] Zinc ricinoleate porous particles 0.3 parts

[0053] Polyhexamethylene (bis) arc laurate 0.1 part

[0054] Antistatic agent 0.4 part.

[0055] The odorless medical oxygen hose TPE material is prepared through the following steps:

[0056] (1) According to the proportion of each component in the formula, put it into the high mixer after weighing, and stir and mix for 10 minutes to obtain a uniform premix;

[0057] (2) Put the above-mentioned premix into a twin-screw extruder to extrude and granulate, and the extrusion temperature range is 130-170°C; wherein, the temperatures of the first zone to the eighth zone of the twin-screw extruder are respectively: 130°C, 140°C, 150°C, 160°C, 160°C, 160°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com