Underwater concrete flexible epoxy anticorrosion paint and preparation method thereof

A technology of epoxy anti-corrosion coating and underwater concrete, which is applied in the direction of anti-corrosion coating, epoxy resin coating, polyurea/polyurethane coating, etc. It can solve the problems of inability to construct at room temperature, high brittleness of anti-corrosion coating, high flexibility of coating, etc. Problems, achieve strong adhesion, good corrosion resistance, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

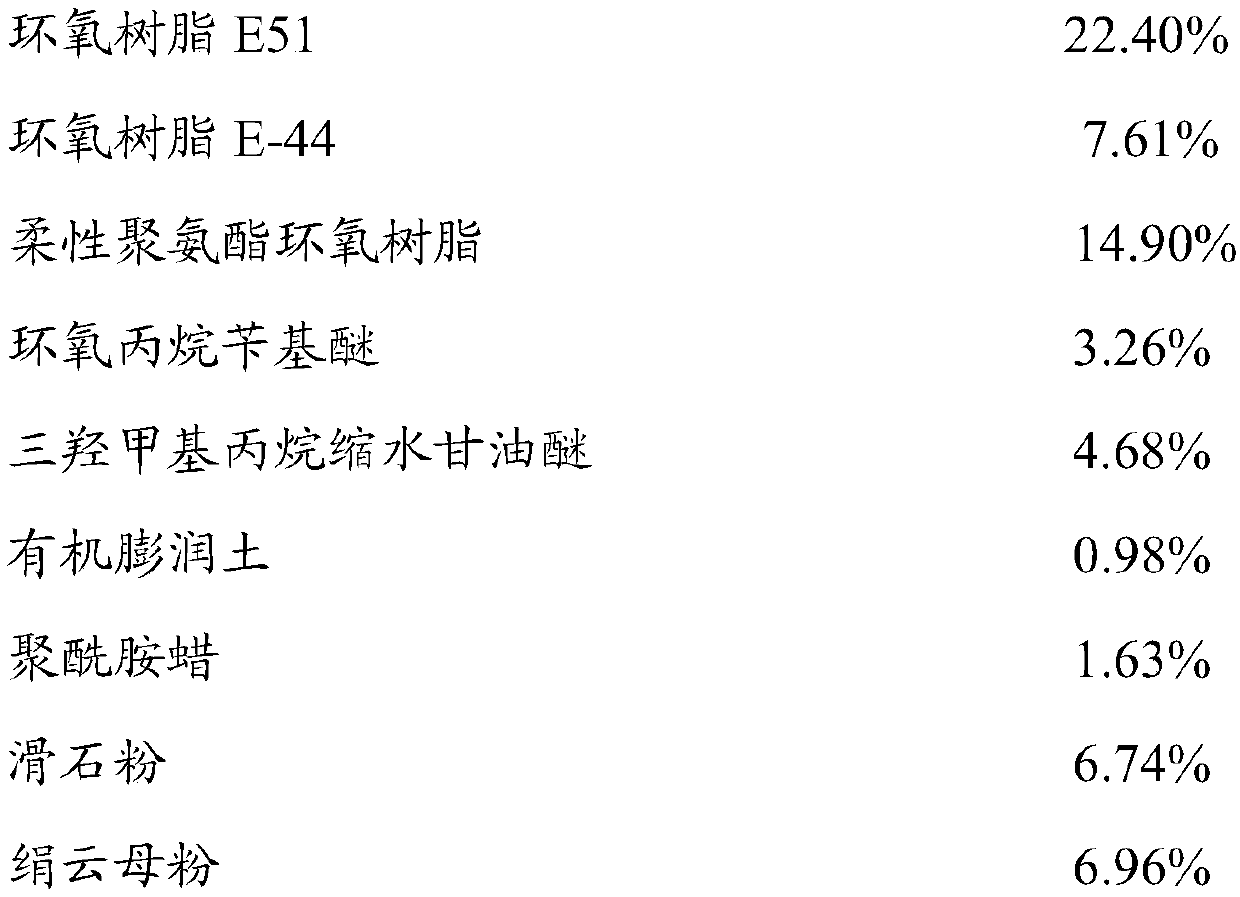

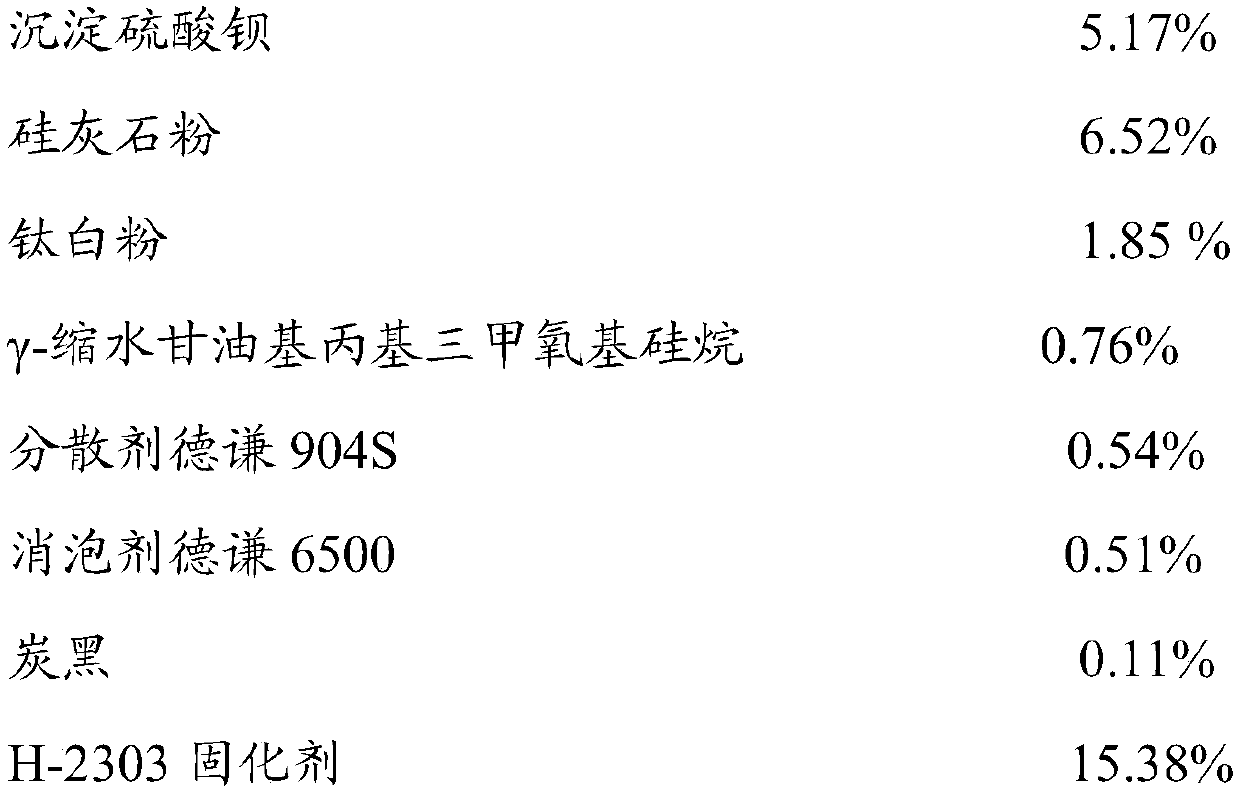

[0022] Prepare underwater tough epoxy anti-corrosion coatings according to the following weight percentages:

[0023]

[0024]

[0025] Preparation of paint:

[0026] (1) Preparation of component A: 22.40% epoxy resin E-51, 7.61% epoxy resin E-44, 14.90% flexible polyurethane epoxy resin 102C-4L, 3.26% propylene oxide benzyl ether, 4.68% Add trimethylolpropane glycidyl ether into the stirring tank in turn, heat to a certain temperature, stir evenly, then add 0.98% organic bentonite, 1.63% polyamide wax and stir, after stirring evenly, add 0.76% γ-glycidyl Propyltrimethoxysilane, 6.74% talc powder, 6.96% sericite powder, 5.17% precipitated barium sulfate, 6.53% wollastonite powder, 1.85% titanium dioxide, high-speed stirring dispersion, plus 0.54% dispersant Deqian 904S and 0.51 % defoamer Deqian 6500 continue to stir and disperse, add 0.11% carbon black for color adjustment after uniformity, and finally grind and pack.

[0027] (2) Preparation of component B: one-compo...

Embodiment 2

[0036] Prepare underwater tough epoxy anti-corrosion coatings according to the following weight percentages:

[0037]

[0038] Preparation of paint:

[0039] (1) Preparation of component A: 24.00% epoxy resin E-51, 8.14% epoxy resin E-44, 15.32% flexible polyurethane epoxy resin 102C-4L, 2.79% propylene oxide benzyl ether, 4.93% Add trimethylolpropane glycidyl ether into the stirring tank in turn, heat to a certain temperature, and stir evenly, then add 1.29% organic bentonite, 1.07% polyamide wax and stir, after stirring evenly, add 5.57% talcum powder, 7.27% Sericite powder, 4.5% precipitated barium sulfate, 6.96% wollastonite powder, 1.93% titanium dioxide, 0.74% γ-glycidyl propyl trimethoxysilane for high-speed stirring and dispersion, plus 0.51% dispersant Deqian 904S and 0.56% The defoamer Deqian 6500 continues to stir and disperse, and then add 0.12% carbon black for coloring, and finally grind and pack.

[0040] (2) Preparation of component B: component B is a sin...

Embodiment 3

[0049] Prepare underwater tough epoxy anti-corrosion coatings according to the following weight percentages:

[0050]

[0051]

[0052] Preparation of paint

[0053] (1) Preparation of component A: 21.55% epoxy resin E-51, 9.11% epoxy resin E-44, 15.89% flexible polyurethane epoxy resin 102C-4L, 2.67% propylene oxide benzyl ether, 4.44% Add trimethylolpropane glycidyl ether into the stirring tank in turn, heat to a certain temperature, and stir evenly, then add 1.22% organic bentonite, 1.00% polyamide wax and stir, after stirring evenly, add 5.44% talcum powder, 6.44% Sericite powder, 6.67% precipitated barium sulfate, 5.33% wollastonite powder, 1.78% titanium dioxide, 0.67% γ-glycidyl propyl trimethoxysilane for high-speed stirring and dispersion, plus 0.56% dispersant Deqian 904S and 0.46% The defoamer Deqian 6500 continues to stir and disperse, and then add 0.10% carbon black for coloring, and finally grind and pack.

[0054] (2) Preparation of component B: componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com