Laser-assisted thermal polarization equipment and method for microscopic second-order nonlinear susceptibility optical elements

A second-order nonlinear, optical element technology, applied in the field of visible-near-infrared optical system materials and devices, can solve the problems of complex process, expensive equipment, unsatisfactory resolution, etc., and achieves good application prospects and improved preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

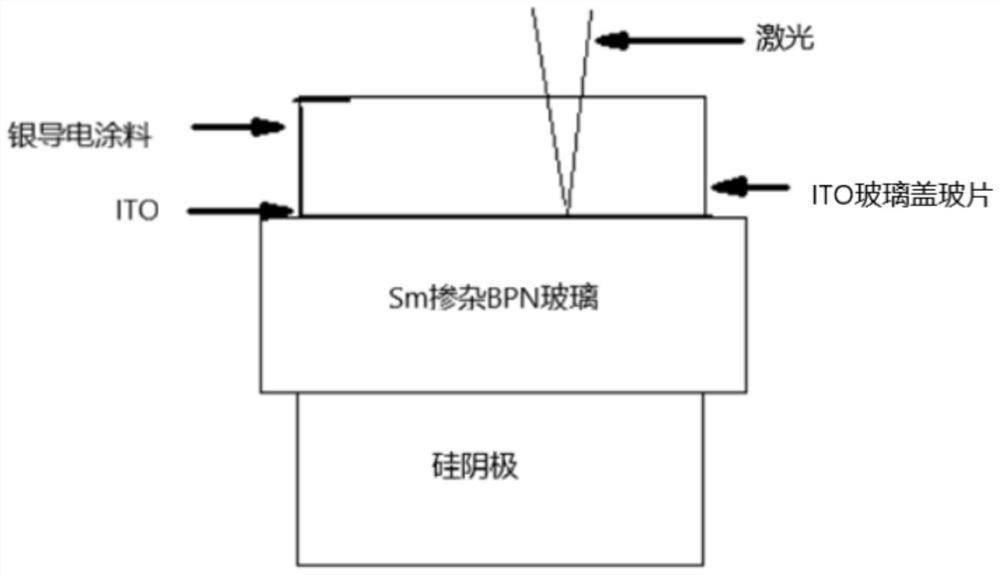

Embodiment 1

[0032] In this embodiment, a laser-assisted thermal polarization device for a microscopic second-order nonlinear susceptibility optical element uses a silver conductive coating to coat the niobium borophosphate (BPN) glass sample doped with Sm3+ ions. The ITO glass covered with silver wire is used as a cover glass on one side of the niobium borophosphate glass sample, and the ITO glass is used as the anode, and the silicon chip is used as the cathode, which is set under the other side of the niobium borophosphate glass sample. Silicon wafers, so as to form a sandwich device of ITO glass, niobium borophosphate glass samples and silicon wafers stacked and assembled, and connect the power supply for the ITO glass and silicon wafers, connect the heating power supply for the niobium borophosphate glass samples, and use it as a cover glass A laser is set above the ITO glass, so that the continuous laser with an emission wavelength of 1064nm passes through the ITO glass and directly r...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this embodiment, a method for laser-assisted thermal polarization of a microscopic second-order nonlinear susceptibility optical element includes the following steps:

[0046] a. This step is the same as in Embodiment 1;

[0047] b. Connect the catheter and the vacuum pump of the sealed stainless steel box assembled by the process device for preparing the optical element by thermal polarization in the step a to the external gas supply pipeline respectively, and firstly evacuate the box to the air pressure in the box by the vacuum pump 5Pa, it takes 20 minutes, then turn off the vacuum pump and fill the box with N 2 Gas to not less than 1.3bar, as the gas of the non-oxidative thermal polarization treatment process, remove the air, water vapor and dust in the box, and eliminate the influence of water vapor and dust in the air on thermal polarization;

[0048] c. This step is the same ...

Embodiment 3

[0055] This embodiment is basically the same as Embodiment 1, especially in that:

[0056] In this embodiment, a method for laser-assisted thermal polarization of a microscopic second-order nonlinear susceptibility optical element includes the following steps:

[0057] a. This step is the same as in Embodiment 1;

[0058] b. This step is the same as in Embodiment 1;

[0059] c. After completing the gas atmosphere setting in the process device for thermal polarization preparation of optical elements in the step b, under program control, use a heat conduction heating device to heat the sample from room temperature at a heating rate of 10°C / min doped Sm 3+ The ionic niobium borophosphate glass is kept warm at 300°C, and the niobium borophosphate glass is heated and kept for 15 minutes to make the temperature of the niobium borophosphate glass as a sample uniform, and place the niobium borophosphate glass in a uniform thermal field;

[0060] d. After completing the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com