Preparation method of anti-radiation fabric for facial mask

A radiation protection and fabric technology, used in cosmetic preparations, skin care preparations, pharmaceutical formulations, etc., can solve problems such as the decline of human health, anti-electromagnetic waves, and poor ultraviolet radiation performance, so as to repair cell damage and reduce cell damage. Injury, the effect of regulating expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

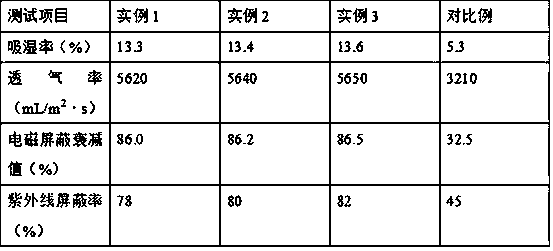

Examples

example 1

[0025]Weigh 300g of bamboo slices and put them into a grinder for grinding, put them into a beaker after grinding, impregnate the bamboo slices with hydrochloric acid with a mass fraction of 6%, place the beaker in a water bath with a temperature of 60°C, and react at a constant temperature for 2 hours. After the reaction The filter cake was obtained by suction filtration. After washing with distilled water for 3 times, the filter cake was impregnated with 15% sodium hydroxide solution, and reacted at a constant temperature for 2 hours at a water bath temperature of 60°C. After the reaction at a constant temperature, the filter residue was obtained by suction filtration. After washing the filter residue with distilled water for 4 times, put it into an oven with a temperature of 80 ° C to dry to obtain a reaction solid; stir and mix the above reaction solid and ferric chloride solution with a mass fraction of 14% in a three-neck flask at a mass ratio of 1:5, Use a stirrer to mix...

example 2

[0027] Weigh 400g of bamboo chips and grind them in a grinder, put them into a beaker after grinding, impregnate the bamboo chips with 8% hydrochloric acid, place the beaker in a water bath with a temperature of 65°C, and react at a constant temperature for 2.5 hours. Finally, the filter cake was obtained by suction filtration. After washing with distilled water for 3 times, the filter cake was impregnated with a sodium hydroxide solution with a mass fraction of 17%, and reacted at a constant temperature for 2.5 hours at a water bath temperature of 65°C. After the constant temperature reaction, the filter cake was obtained by suction filtration. , wash the filter residue with distilled water for 6 times, put it into an oven with a temperature of 90°C and dry it to obtain a reaction solid; stir and mix the above reaction solid with 16% ferric chloride solution at a mass ratio of 1:5 and put them into a three-necked flask In the process, use a stirrer to mix and stir at a speed o...

example 3

[0029] Weigh 500g of bamboo slices and put them into a grinder for grinding, put them into a beaker after grinding, impregnate the bamboo slices with hydrochloric acid with a mass fraction of 10%, place the beaker in a water bath with a temperature of 70°C, and react at a constant temperature for 3 hours. After the reaction The filter cake was obtained by suction filtration, washed 4 times with distilled water, impregnated with 20% sodium hydroxide solution, reacted at a constant temperature for 3 hours at a water bath temperature of 70°C, and obtained a filter residue by suction filtration after the constant temperature reaction. After washing the filter residue with distilled water for 8 times, put it into an oven with a temperature of 100°C and dry it to obtain a reaction solid; stir and mix the above reaction solid with 18% ferric chloride solution at a mass ratio of 1:5 and put them into a three-necked flask. Use a stirrer to mix and stir at a speed of 400r / min for 40min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com